|

|

Maintaining Johnson/Evinrude 1965 – 1968 (General Repairs) |

|

Johnson, Evinrude, OMC, outboard motor, outboard motor repair, outboard troubleshooting, 6 hp, water pump, carburetor,

|

|

Maintaining Johnson/Evinrude 1965 – 1968 (General Repairs) |

|

One thing that I want

to convey here is that I write only on motors that I have actually worked on, and

over a period of MANY years, consisting of many THOUSANDS of hours, and then

more in maintaining/updating them. These articles are motor specific,

HOWEVER if you are having a diagnosis issue, my Trouble Shooting article covers

MANY more aspects that may help you diagnose your issue.

CLICK HERE

for access to that article.

You do not see that

many of these little motors, simply because of the few number of years

that they were produced (4), however they would have been cheaper and lighter

than the 6 hp.

The Johnson motors will have a HP rating on the cowling, while the Evinrude motors will only have a plaque labeled "Ranger" on the top front of the cowling, with the only HP designation being on the nameplate mixed in with the starting procedure.

One difference you will notice other than the color, will be that as seen in the above header photos, the Evinrude cowlings will be a different shape than the Johnsons, other than that, the parts interchange. I have a feeling that this cowling change could have been a marketing test, however have found that the basic cowling is the same fro the 6hp of the same years, only the latch is different.

These are very light weight and simple two cylinder motors, magneto ignition, and no gear shift, which means no neutral and the prop is turning at any time the motor is running. Any reverse is obtained by rotating the motor 180 degrees.

If you see any indication in this article pertaining to Right hand or Left hand, this will be determined as if you were standing at the rear of the motor looking forward.

Year of Manufacture : This is important in any repair, for obvious reasons. These 1965-1968 Johnsons were designated LD models. They were made in standard 15" shafts or the LDL long 20" versions which was designated by a 3rd letter L in the model number. And in 1968 they added 3 different suffix letters B, E & M, so there must have been some slight changes. The Evinrude model numbers started in 1965 as 5502 or 5502S, this apparently equated to the first number as 5 hp, second number of 5, referring to 1965 and then I have not figured out the other 2 or 3 except possibly a model distinction as there could have also been a 5 hp motor made in 1955. This same motor in a (20") longshaft would have been 5503/S. The Evinrude model designations are confusing to say the least.

Even though longshaft motors were made, finding one of this series

would be quite

rare, as in those days most of these small motors were used on small fishing

boats and not as kicker motors for larger fishing boats which in most cases

require the longer shafts.

There should be the model and serial number on riveted on 1” X 2” aluminum ID plate on the LH side of the transom mount bracket (looking forward). Sometimes this ID plate can get removed.

In this listing below for Johnson the LDL indicates Longshaft

Johnson LD / LDL 22 = 1965

Evinrude 5502/5502S = 1965 -- 5503 = Longshaft

LD /

LDL 23 = 1966 Evinrude

5602/5602C = 1966

LD /

LDL 24 = 1967 Evinrude 5702/5702

= 1967

LD /

LDL 25 = 1968 Evinrude

5802/5802B, E, M = 1968

Statistics For These Motors :

These motors develop 5

hp @ 4000 RPM

Cylinders

2

Bore diameter 1.940"

Stroke -

1.500"

Displacement

8.84 CI

Starter -

automatic rewind

Bearings -

bronze bushings, both mains & rod

Carburetor -

OMC, metal float type

Choke -

Butterfly, pull knob

High speed jet, Preset

Idle jet - 3/4 turn out

Throttle

Control - Side lever

Fuel capacity - remote tank

Fuel/Oil mix is (24:1)

Point gap is .020"

Plug gap - .035", Champion J6C or J8C spark plug.

Flywheel key - Woodruff .153" wide x .235"

thick x .603" long

Flywheel nut - 3/4" wrench

Water Cooled - Rotary vane water pump

Gearbox oil - 90 W gear

oil

Gear Ratio -

Prop. dia. & pitch- - 3 Blade, LH, 8" X 7 1/2"

with 1/2" bore

Shear Pin -

1/8" (.125") diameter X 1.250" OAL

Prop nut retainer pin - 3/32" X 1"

Prop nut - special nut, 7/16" X 20 TPI

Paint Color -

Weight

Exploded Parts

Lists :

For a

internet link to a marine parts seller

CLICK HERE

that has exploded views as shown below in this article. From

this business, you can identify the numbered parts and purchase parts

online from them. On this model the above company shows some gearbox

parts (seals) as unavailable or NLA, however if you go to

THIS COMPANY, and go

to a 1968 year (the oldest they list and still within this model years

of production), they list many of these parts.

Similarities : Some of the following parts are shared by other size motors, this head gasket OEM # 329103 fits 5 hp 1965-1968, 5.5 hp1959-1964, and 6 hp 1965-1979. Gearcase seal kit 6 hp 1968-1979

Then there was also a 4hp that is similar and followed this 5hp from 1969 to 1979 and used a Johnson model of 4R70E. This 4hp was very similar to the 5hp but used a totally different pivoting type spool type starter and the throttle lever is simpler, being a just a rod on the RH side. These would have had the electronic ignition however. It also used the remote fuel tank as the 6hp, while other motors smaller, utilized smaller internal tanks. Probably the same lower unit/gearbox was used on both. And it appears that no thermostat was used on this one, possibly because of lower RPM did not create as much heat. And it could be purchased in either the standard horizontal gearbox or the angled "Weedless" unit.

Flywheel : To get to the electronics, the magneto which is under the flywheel, you will need to pull the flywheel off the tapered shaft of the crankshaft. Removal of this nut needs a 3/4" socket. If it is so tight that you can not loosen it normally, then try holding onto the flywheel and tap the wrench with a medium hammer to jar the nut loose initially. If that does not work then you will have to resort to a strap wrench or a air impact gun.

Most times if you just loosen the flywheel nut a few threads, (leaving it about even with the shaft end) then hold onto the flywheel by wrapping your arm around it and lift up enough to put a lot of strain on (almost holding the motor upright) then rap the nut HARD with a HEAVY brass mallet, the flywheel should pop off the crankshaft tapered end. The reason for the brass hammer is so it does not damage the nut or shaft threads. You could get by with a regular hammer if you are careful. One hard rap is better than a dozen love taps.

If this does not pop the flywheel loose, then you will have to resort to a flywheel puller as shown in use below. These motors have a thin aluminum cover held in by the flywheel nut that covers these puller holes. There are 3 holes that are threaded 1/4" X 20 TPI. The pullers usually have 3 slots milled in the top flange to accommodate the bolts to be threaded into corresponding threaded holes in the top of the flywheel. This puller could be also use if only 2 opposing holes were there. The large bolt in top is threaded into the puller boss. In use, you thread the 3 smaller bolts into the flywheel so that they will allow the puller to set evenly on top. You then tighten the large bolt into the puller, which puts pressure on the crankshaft end, pulling the flywheel up. If it comes really tight, then with the large bolt's pressure on the crankshaft, rap the large bolt head with a hammer, which usually will help and pop it off.

| Illustration from factory manual | Home made flywheel puller in position |

|

|

This flywheel is

located in the proper position on the crankshaft by a 1/2 round woodruff

key. This proper position is critical as it times the points

opening to when the spark fires the spark plugs (because of the location

of the magnets in the flywheel in relationship to the coils). This position is

also just as critical on the later CDI ignition. If this key gets

damaged or partly sheared, the motor will not run well, or possibly not even start.

Magneto Ignition, Points & Condensers : The ignition is magneto type, using points and condensers. Points were universal from the 1.5 hp up to 30 hp from 1952 to 1976 and then even to some 40 hp motors to 1973, with settings always at .020". Condensers pretty much followed this pattern from the 1.5 hp to the 35 hp at 1976 (excluding the 9.9/15 which are different).

On these motors, all

the points are set at .020". If you get a motor that is not firing,

pull the flywheel then clean up the points with a point file.

The last point file I purchased (2009) cost $7.50 from a auto parts dealer.

Sometimes all you are doing is to just remove oxidation off the contacts

if the motor has sat for some time. This can be usually

remedied by running a point file thru the point openings to freshen up

the contact metal.

Most of the service

manuals say to replace the points if worn or burned. Well, take it from me you

can usually clean them up for many more hours of run time afterwards.

However if the points are really pitted, that is a sign that the

condenser is not performing to capacity. If this is the case, then

it is recommended to replace them, along with the condenser. The one thing that does wear is

the points rub bar if it has not been lubricated from the last repair.

If you replace the points and still have running problems, you may well could have contaminated the point surfaces with oily fingers. If this may be the case, remove the flywheel, rotate the crankshaft until one of the points are open, wash it off with lacquer thinner, rotate and do the other set. Then insert a section of brown paper shopping bag in the points, rotate the crankshaft until the points close then pull this paper thru the points. This should clean them.

This older ignition using condensers,

if they start to break down, the motor can start and run for a while, but when

things warm up, the condensers and or coils can begin to short out internally

causing the motor may

die. You can crank until you are blue in the face but it refuses to start.

Let it set for an hour to let these components to cool down and it MAY then restart. Time to change condensers,

however hang onto the old ones as long as possible as the newer manufactured

ones have a reputation of not being made that good.

A condenser is simply a lot of aluminum foil wrapped between waxed paper as an

insulator. If the paper starts to deteriorate, after running for a while,

the metal will heat up then expand. IF this happens in a location where the

insulation is bad the metal shorts out to the next wrap, nullifying or shorting

out to ground so no output is achieved. But IF this is the case, many times when the

condenser cools down, the short goes away until it warms up again. Once it

has done this process a few times, then the short becomes rather permanent and the

condenser is inoperative

If that driver coil (under the flywheel) starts to fail, is cracked, or starting to melt down,

or whatever, there is a

possibility that it would also operate when cold, but fail by shorting out when heated

up by the running of the motor. However do not just replace them because

they are oozing black tar like goo. They may still run for some time.

For a more in depth article on magneto ignition along with fine tuning the point settings CLICK HERE. This article is directed at the 1974-1976 9.9/15hp OMCs, but the principal is the same for about all of the magneto ignition OMCs even with those that have external coils.

At the top of the photo below you will see a white pivoting arm, this is the throttle friction system that works against serrations on the lower outside of the timing plate.

| Top view of the timing plate with both the points, condensers & coils |

|

|

Coils :

Coils for these points

and condenser motors are the same from 1949

mostly up thru 1973 from motors 5.5 hp thru 40 hp. This motor's

coils are mounted on the timing plate under the flywheel. These coils, especially

those in the 1960's motors have a reputation for cracking and allowing

moisture in and then starting to break down, creating problems. The

factory (or supplier) changed the plastic formulation

on the coils at some stage and the replacement ones are considerably

better. If the coils have cracks that you can see,

they maybe also have cracks below which could be allowing electricity to

short out to the plate. If you are on a tight budget, remove the

coils, dry them out, then paint the cracks with a thick paint or epoxy,

which may get you by.

About 60% of the older motors I have had, needed one or more coils replaced,

and the current replacement costs range from $20 to $25 each,

which would be financially unviable for someone not working on their own

old motor with the price of labor at $85 an hour to not replace them.

But the mechanic is covering his behind, because of you possibly later having

one/them fail and he would get the

motor back for free repair only to find that in his saving you money he

actually got an unhappy customer and him a repair where he felt he had

to cover at least part of the second repair.

After doing some web surfing I found a website by Doug Penn where he showed on a video how to test both the coil and condenser of older OMC outboards. CLICK HERE for a coil testing video, and HERE for a condenser testing video.

Recommended Spark Plugs : The recommended spark plugs for these 5hp motors were Champion J4J, however if you are using it for a lot of trolling, I go to the hotter J6C or hotter yet the J8Cs. The recommended spark plug gap is set at .035", however with a well used motor where the rings may be worn and may oil foul the spark plugs, old some mechanics may recommend try to open the plug gap up from the normal to .035" or even .045" which seems to allow the plug to run hotter and cleaner. However maybe a better solution would be to a move to a hotter plug, like the J6C, especially when doing a lot of trolling.

Carburetor : To remove the carburetor, you will need to disconnect the fuel line, the choke lever and low speed knob (sometimes called the idle jet). This Rich-Lean knob just pulls off the finely splined shaft straight forward. After that, you will have to then remove the two top bolts (using a 5/16" box wrench) from the recoil starter spool mounting plate. Very carefully pull the complete starter to one side just so far that do not pull the recoil spring out of the base. You have to remove the starter to access the LH carburetor mounting nut and remove that nut. Replace the starter unit then bolt it back in to keep the spool and the spring from coming a nightmare. Remove the RH carburetor nut, slide the carburetor forward off mounting studs.

There is a coil spring attached to the carb roller arm and the other end goes in a small hole in a cast in stud on the top of the motor block up under the flywheel. You need to use a needle nose pliers to unhook this spring, and again to reattach it.

The carburetor is the basic simple standard unit

and possibly the first to use the fixed main-jet style (#15 shown in the

illustration below). Earlier motors prior to this model had an adjustable

main-jet in place of this fixed jet and the corresponding #44 plug screw. You will have to loosen and remove the rewind

starter spool so you can get to the throttle lever pivot nut so you can

then get a wrench on the port side carburetor nut.

| Exploded view of carburetor |

|

You can usually tear the carburetor apart, soak it in a carburetor cleaner overnight, blow it out with compressed air and reassemble without purchasing a repair kit. The float is varnished cork and may look cruddy, but if it is still intact and seems to float in gasoline it should function. All that is usually needed is to check to see that the float level is with the bowel flange when assembled without the bottom bowl on and turned upside down. If not parallel, then bend the metal stop tab on the float needle valve area to adjust the float level. If the float is not set at the correct level for the shut off point under pressure from the fuel pump in the carburetor, this could cause motor to run lean or rich.

Some carburetor repair kits cover a wide range of HP ranging from 5hp even up to 20 hp, however do not think just because the kit is the same for a 20hp as it is for the 6hp that they use the same carburetor. The kits may have numerous extra parts, as main jets where you just use the one required for your motor. The breather throat of the carburetor may also be a larger diameter for different hp of motors.

The main jet orifice in the bottom of the bowl has a recess on these models and be full of crud, even though they look clear. On the later carburetors there is a clean out plug in front that you can access this orifice. Use a proper fitting screwdriver to remove the orifice, but be sure there is no debris in or behind it. Be sure the plug screw has a good sealing gasket. This plug is in the same location that the early carbs had a adjustable main jet.

Inspect the idle needle jet to see if it is bent or has the tip broken off, straighten if need be or purchase a new one. Reinstall this jet needle / rich-lean screw, check the packing nut for tightness to insure there is no air leak around the shaft. The correct way to adjust this low speed needle, is to turn it all the way in until it is lightly seated. You then turn it back out 1 1/2 turns. That becomes a reference point for further adjustment. I like to be able to get a equal rotation each way so set the knob at about what would be 4 on the top. This should give you a basic setting. Once you get it where you want, you can pull it off , then reposition the knob where you want it.

With the motor warmed up and the twist throttle in a SLOW position approximating your intended slow/trolling speed, turn this low speed needle jet in about 1/8 of a turn, let the engine run for about 15 seconds to respond to your new setting. Do it again then wait for the results. A cough is indicative of a rich mixture. Too lean it will just die. When you make this change and the engines either sputters or wants to die, back it off the the last position then this should be close to the ideal setting. If you go to rich it will cough AND then die. You can now pull the idle knob forward and off the splined shaft, reposition it so that the knob pointer is down so you will have movement either way from this position for fine tuning if needed. This low speed setting does not effect the high speed running of the motor. However it you set it too lean, you may later have a issue with it not wanting to start when it is warm.

One thing if you look at the top of this carburetor, the 1/8" hole at mid-section topish is not plugged with a lead shot like all the rest. My thinking was did I loosen it and loose the plug? Well, after I got it running I covered that hole with my finger and the motor wanted to die. After numerous tries, I decided it was not supposed to be plugged anyway and probably there as a vent to alleviate any vacuum inside the float bowl.

In reinstalling the carburetor to the intake manifold, you may have to position it so that it just starts onto the studs, then start threading the nuts on equally before finally tightening them. What I am saying that there may not be enough room to start the LH nut if you have the RH nut tight.

There is no breather box on this motor as the mouth of the carburetor is open behind the front of the cowling.

| Starboard side view of carburetor showing the idle jet shaft, choke rod & the throttle linkage arm/rod to timing plate. |

In the center of the

cowling is the Slow-Speed (idle) knob & choke on left |

|

|

|

Throttle Control : The throttle control lever is located on the left side of the motor and raises high up on the side of the cowling. It has a friction detent system so the lever easily stays in place, yet movable with a clicking sound. This is rather unique in that the left rear side of the timing plate has vertical serrations and as seen in the second photo below a white plastic arm at the upper rear of the block and a spring loaded plunger that presses this arm against the serrations. The main throttle arm goes in and under the lower cowling, across to the other side and is then attached to the throttle cam by a arm and wire rod.

| Here on this model 5502 (1065) you can see the throttle lever & the speed indication decals on the LEFT side of the motor, (NO TWIST GRIP THROTTLE) |

|

|

Fuel Pump : This series of motor utilized 2 different fuel pumps, depending on the year of production. The first 2 years of production of this model (1965/1966), used an old style fuel pump. This early fuel pump was used on other motors as well, like at least the 9.5 hp of the same years, which is shown by clicking HERE.

This Both utilized a filter screen on the intake of the fuel pump. The early model fuel pump, under the center screw surrounded by a seal rubber ring, which secured the screen cover allowed the owner to access this screen as seen in the LH photo below. This screen and gasket can not be placed on wrong as there are 3 small alignment studs made into the plastic that has to align. When the factory went to the new style fuel pump on this model in 1967, this pump also included a fuel filter screen, as seen in the RH photo below the black plastic inlet is secured by a single center screw. By removing this screw, this fuel inlet cover can be removed, UNDER and pressed into the underside is a fine stainless steel filter screen. Also is a Neoprene gasket just the shape of this cover. On these the cover and gasket have 4 scallops corresponding to the 4 fuel pump bolts. If this fuel inlet needs to be rotated for better fuel line alignment, it can be rotated 4 different 90 degree locations.

| Here you see the early style fuel pump | Here is the later style fuel pump |

|

|

|

Shown in the photo below is what you see when removing the center screw of the old style fuel pump. This gasket appears to be made of rubber impregnated cork. There are 3 short protruding studs that all 3 have to align and fit before it will align and tighten down on the body.

| Here is the cover cap, screen & gasket for the early fuel pump |

|

|

Repair kits seem to be non-existent for these early pumps, however there are still some filter screens and gaskets available. But it is possible to convert over to the later small square style fuel pumps rather easily as the mounting gasket #0303615 is used on both styles of fuel pumps. In adapting the newer style pump, you will have to replace the two 10-24 X 1 1/2" mounting bolts with 2" bolts. You may also have to replace at least one of the fuel lines.

These later fuel pumps are pretty universal, the same one fitting most all these small motors up to 40 hp until about 1987. For a link to the rebuild procedure CLICK HERE.

| Here you can see the early fuel pump & throttle linkage arm & rod to the timing plate |

|

|

Oil Tube for Top Main Bearing : All of the fuel 2 cycle motors the fuel/oil mix passes through the crankcase on it's way to the cylinders. This oily fuel is what lubricates the internal parts. Most of it goes right through the crankcase, carried along with the airflow to the cylinders and burned upon firing by the spark plugs. But a bit of it "rains" out or splatters up against the inner crankcase and piston walls, then drains down settling at the lower main bearing. For some vertical shaft 2 cycle motors, this being one, there is collection pocket around this lower bearing housing. This oil collected in the bottom pocket is pumped to the top main bearing by the alternating suction/pressure of the action of the 2 cycle operation.

It is all accomplished by taking advantage of the different pressures in the crankcase. There is no mechanical pump like what you would find in a four-stroke motor. This oil is routed thru a small oil line to the upper crank shaft main bearing to provide better lubrication to that bearing and is located vertically on the RH side of the block just in front of the fuel pump. This tube is made of rubber (or copper when found on older models). Also it is usually painted the same as the power head, which makes it even a bit harder to identify unless you know what you are looking for. This tube needs to be free and clear for the oil to be moved upward.

Fuel Tank & Lines : These motors were apparently the first of this smaller size that utilized a remote fuel tank and quick disconnect couplers and were new enough (made after 1959/1960) which use same the vacuum tank and the single fuel line and fuel pump commonly found nowadays.

Recommended Fuel / Oil Mix : On these 2 cycle motors you have to mix the oil with the gasoline to lubricate the internal parts of the motor, so you need to know how much gas you will be needing, add the oil before you fill the fuel tank so that the oil mixes better than just dumping it in after you fuel up. However if that is not possible, then guess, add a majority of what you think it will take, top off the tank and then add the rest matching the amount of gasoline it took to fill the tank. If you are using portable fuel thanks, before hand, when you fill it, make you a stick gauge, by adding 1 gallon at a time, use a clean 3/8" or 1/2" dowel start filling the tank, mark the dowel at each gallon you add, then you can use it as a measuring stick. This way you can refill a partly full tank with the known amount of oil.

The formula shown below will be on all modern 2 cycle oil sold in the last 30 years or so. On most all of the pints and quart plastic bottles of TWC-3 oils there will be a narrow clear vertical window on the edge of the bottles. On the sides of this window will have numbers representing ounces and Milliliters for other parts of the world. Or you can purchase special measuring containers showing different ratios and the amount of ounces needed.

Fuel/oil mix on all the OMC motors that have needle roller bearings (this motor included) is 50-1 of TCW-3 standard outboard oil. However I have found that since I troll much of the time, other than getting there and back, I like to use a mix of 75-1 but of a SYNTHETIC blend oil instead of the standard oil. This gives me at least the same or better motor lubrication, plus it gives me less smoke at a troll and the spark plugs last longer before fouling.

A quart has 32 ounces of oil in it. So for a portable 6 gallon tank to fill it using the 50:1 ratio would take 16 ounces, (1 pint) or 1/2 of the quart.

|

FUEL MIXING TABLE |

|||||

| Gallons of Gasoline |

Gasoline to Oil Ratio |

||||

|

Ounces of Oil to be Added |

|||||

| 16:1 | 24:1 | 32:1 | 50:1 | 100:1 | |

| 1 | 8 | 5 | 4 | 3 | 2 |

| 2 | 16 | 11 | 8 | 5 | 3 |

| 3 | 24 | 16 | 12 | 8 | 4 |

| 4 | 32 | 21 | 16 | 11 | 6 |

| 5 | 40 | 27 | 20 | 13 | 7 |

| 6 | 48 | 32 | 24 | 16 | 8 |

The official OMC fuel/oil mix for most outboard motors in this year ranges has for years been 50:1. This means 50 parts of regular gasoline to 1 part of outboard motor oil. Remember that this was before unleaded gasoline or even possibly an octane rating that was listed at the pumps. The factory service manual states that any gasoline that can b e used in automobiles will work in these motors, however little will be gained by using premium fuels. The later manuals recommended fuel is 87 octane gasoline. Early on for the 2 cycle motors the recommended oil was regular automotive 30 weight motor oil, then the outboard industry came up with any TWC oil, which then finally evolved into the latest which is TWC-3 outboard motor oil. You probably will not see much of the older TWC-2 oil out there anymore. You can spend your money and purchase OMC oil for about $6.50 a quart, or buy a name brand quart for $3.59. Sure the manufacturers want you to buy their oil, and for a new motor under warranty, it may be advisable to do so. But the consensus from many experienced boaters is to use any good brand of oil, as long as it has the TWC-3 rating, it meets or exceeds the manufacturers specifications. The TWC-3 represents, Two cycle, Water Cooled, type 3 formula. The formula 3 has decarbonizing additives designed to be more compatible with the newer non-leaded fuel.

So from the above information, you can see that fuel and oils have changed dramatically since these motors were first brought out in 1965. In this instance, times have changed for the good, as we now have a better gasoline along with way better outboard oils.

DO NOT use oil designed for your air cooled weed whacker or chain saws as these air cooled motors run a lot hotter than the water cooled outboards. The water cooled outboards require the specially designed TWC-3 oils.

Tiller Handle : The tiller handle is simply that, no provision for any speed control on it that you normally see on these small motors. The speed control is a lever on the left hand side pivoting from under the carburetor, with the handle raising up as if you would think it was a shifting lever, only on the cowling behind it will be a decal reading FAST - START - STOP.

To Start It : These points and condenser motors when COLD usually won't start in the minimum throttle position so line up with the lever with the "start" on the side of the upper cowling. If it does not fire within the first few pulls oR you are in doubt and if the markings have disappeared, then advance it to about a medium/fast setting as it will start if set faster, but will NOT start if set lower. Pump up the fuel line primer bulb until it becomes hard. Pull the choke knob out and with a quick effort pull the starter rope. If everything is functioning, it should start, possibly on the first pull, but usually within the first 3 pulls.

To Stop It : There is no kill button on these motors, you just move the throttle lever as far to the rear as it will go and the motor should die, it not, then choke it to kill it.

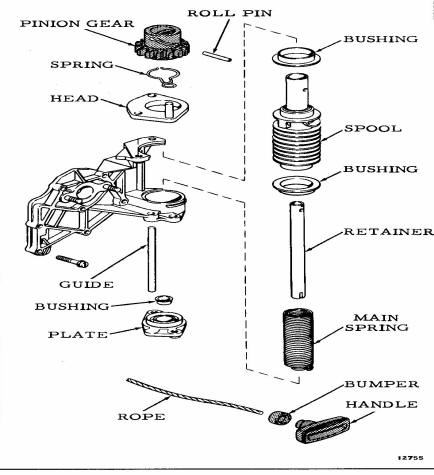

Recoil Starter : The recoil starter uses a rope type spool system that works very much like an automotive type starter unit only manually. As you pull the rope, the pinion gear slides upward by means of a cam riding on the cam roll pin. This engages the starter pinion gear with the flywheel gear, rotating the motor.

On the larger motors this type, these starters do not rotate the motor fast enough unless you really get mad at it to give a good compression reading or even start the motor if your adjustments are a little off. However on this small motor, that is usually not an issue.

If you have to replace the rope, the service manual says 66 3/4" is the proper length. One thing you need to know if you have disassembled this unit, is that the main spring is ONE spring wound as two (one inside and another outside). When rewinding, you wind it REVERSE as to what you would think. If you do it the way you would think is needed, the lower inner part of the spring EXPANDS to where it may not be reusable. And aftermarket replacement springs sell in the $75 to $100 price range.

In rewinding this spring, a LARGE screwdriver and Crescent wrench is inserted in the slot in the top of the retainer shaft, rotate this 16 1/2 LEFT HAND rotations, insert the roll pin through the retainer shaft hole, the spool's pin hole AND the pinion gear slot. If there is any left over starter rope, it should be shortened at the pull handle so that the rope lays at the very bottom of the grooves, and not climbing up on any rope coils.

For a more detailed instructions (factory and my own personal) go to my 6 hp article by CLICKING HERE , as these 5 hp motors use the same starter assembly as many of the other sizes in/near the same HP range.

| Front view of the carburetor & spool type starter | Here is the illustrated starter unit |

|

|

|

Thermostats : These are the same from 5hp to 55hp for years 1959 to 1994. Since these motors are usually used in fresh water only, they can usually be removed, cleaned up with no problems. If the motor was designed to use a thermostat, do not run it without the thermostat as the motor will not run in a high enough temperature range to allow the motor operate at it's efficiency level. Plus if you troll it a lot the spark plugs will foul a lot because they are not up to a proper operating temperature.

Thermostats were interchangeable from 5hp in 1965 to 55 hp in 1992.

This motor I owned had a pocket for a thermostat, but it was missing. But after surviving for 50 years, it is hard to say what kind of "mechanics" worked on it. Then looking at the illustrated parts list for this model, none was shown, so maybe they found with that small a motor, it may have ran OK without one??

Water Pump : To remove the lower unit/gearbox, there are 4 bolts at the lower part of the exhaust housing that attach the gearbox to this housing. Remove them. The gearbox and driveshaft should slide down and off the water tube that is attached to the bottom side of the powerhead. Do not try to carry this unit by only lifting on the exposed driveshaft as it will pull out of the gearbox. You can then remove the two screws holding the upper water pump housing, which allows this housing to be slid up the driveshaft, exposing the impeller.

On the upper end of the driveshaft you will see a lower brass cup, spring and upper 1/2 of a shaft seal. Remove them up and off the shaft. HOWEVER retain them in the relationship that they came off as the upper part is part of the seal and needs to be replaced properly. Below this seal unit is a 3/32" X 11/16" stainless steel roll pin. Drive it out and save with the seal unit for reassembly.

These water pump impellers are the same that was used on most of the small motors up to about 8 hp from 1952 to 1978. OEM #0777819. The early motors used a metal upper pump housing and required impeller #0434424, or if aftermarket, Sierra #18-3001. If the motor uses the later plastic pump housing use impeller #0763735 instead. The impeller key is made similar to a Tee, but the single protrusion is round going into a hole in the driveshaft, where the to of the Tee is square, fitting into the impeller keyway. The motor I worked on, this impeller had a Nylon hub and the key had worn a slot in this hub so it would rotate about 90 degrees around the shaft. Time for a new impeller. This impeller has six vanes and dimensions are approximately .50" thick, 2.74" diameter, shaft hole ID .440"

Water Pump Re-Assembly : I have found it best to inset the impeller into the housing with the vanes rotated as if the motor was being rotated clockwise looking from the top. I usually lubricate the vanes with a slight amount of oil or Vaseline. Place the impeller in/on the water pump housing, being sure you install the impeller in the same rotation that the motor will be turning, RIGHT HAND looking down. Rotate the impeller as you force it into the housing. Move the impeller so that it's hole in the hub is pretty much in line with the housing shaft hole. All vanes need to point the same direction. Install the impeller key #13 in the driveshaft. This model's key are made in the from of a Tee. The bottom peg is rounded that goes into a hole in the driveshaft, leaving the top of the tee which is rectangular slide into the square notch in the impeller.

Slide the water pump housing (with the impeller down in place) onto the driveshaft, moving it enough to get the impeller and housing to both accept the driveshaft. Be sure the impeller key in the shaft retainer hole has the hex part of the key vertical to be able to accept it's mating slot in the impeller hub. Slide the housing farther down onto the key. It wants to turn sideways slightly enough during assembly that you need to have it rotated very close as the 2 slide together to assure it is right. The water tube outlet will be to the rear. Bolt the housing down to the lower unit base using anti-seize on the threads.

One thing when reassembling anything on the lower unit that MAY get exposed to water (especially salt water) is to coat all the bolt/screw threads with a anti-seize compound. A later mechanic will thank you. As this motor all four of the lower unit fastening bolts to the exhaust housing were corroded enough that they all twisted off, requiring more tedious work to remove. As viewed by CLICKING HERE.

The above also applies to the upper driveshaft spline, grease it with a good grade of waterproof boat trailer axle grease. This will ensure that the next repairman will be able to remove this lower unit/gearbox when he needs to replace a water pump impeller.

Driveshaft Seal Assembly / Alignment : Upon reassembly, the one thing different than the normal water pump reassemble is installing the 3/32" dowel pin (part #8 in the illustration below) in the driveshaft upper section. This pin holds the seal unit up, putting spring pressure onto the bottom of the lower crankshaft seal unit.

In the illustration on the left of the photos below, number (4) is the actual seal, with the pin pushing the retainer cup and spring forcing the seal up to bear against the #2 plate. The lower spring retainer washer (#6) has "bumps" on the bottom of it. The pin (#8) drives against the bumps, turning the washer. Friction turns the spring and carbon/ceramic seal. This seems to be a rather unorthodox method, but it apparently works. This seal is very similar to those used for the older 5.5hp, 7.5hp and newer 6 and 8hp motors as well.

If you look at the spring cup retainer you will see two bumps on the bottom. These protrude just low enough to engage the retainer pin, which then drives the spring and O-ring seal, while the upper seal plate stays in position just by friction pressure against the gasket.

When you remove the lower unit, #1 and #2 may stay stuck in the upper part, and fall out when you are not aware, so either take them out or be careful. #1 is a gasket to the lower part of the block. #2 is a stainless steel upper seal plate. #3 is an O-Ring seal. #4 is a fiber/Nylon cup that holds the O-Ring in position in a shallow groove. #5 is the spring. #6 is the cup spring retainer. #8 is the cup retainer roll pin. #13 is the impeller key and of course #12 is the water pump impeller. The old O-Ring was so worn that I could not get a good measurement, (and lost it) but found one that was 3/32" thick by 5/8" OD and 7/16" ID that fit. This could be thinner but still have a 7/16" ID and work. Before you fully assemble the seal, apply a bit of Vaseline or trailer axle grease to the O-Ring/upper seal plate.

Once you have all these seal parts installed on the upper driveshaft, you can proceed to install the gearbox unit back up into the exhaust housing. As you align the driveshaft spline, you also have to align the water pump tube in the mid-section into the water pump outlet grommet. This tube is rather soft cooper and may get bent, so be sure that it is shaped so that it is not close enough to be dragging on the driveshaft that it may wear through. You should have to insert this water tube into the water pump outlet grommet first, push the gearbox up, locating the hole it needs to enter in the block, then rotate the prop slightly to allow it to enter the crankshaft spline. You should now feel the spring compressing as you push up the gearcase into the driveshaft / crankshaft spline.

In the photo below on the right, you can see the O-Ring protruding upward between the seal plate and the cup.

No worry on this one to also simultaneously align the shifting rod linkage as there is none.

| Illustrated view of lower crankshaft seal assembly | Actual view of the seal assembly |

|

|

No Overboard Water Indicator on Early Motors : These motors were early enough that they did not have an overboard water indicator (pee hole) which did not came into being until after these motors were discontinued. They do have a "water outlet" as seen in the illustration below, which on this motor are four small holes on each side of the mid-section of the exhaust housing. These outlets allows for some outlet water to mix with the exhaust gasses to cool the housing and at the same time allows only a small amount of exhaust with some spitting water, as an indicator of sorts, some may call it second exhaust port, however in actuality, in these smaller engines you could say it is an idle bypass, because at idle speeds there is not enough exhaust pressure to overcome the under-water pressure out the larger hole near the prop.

I have traced the water flow in the service manual and found that a simple modification to the thermostat cover can be made to create a water indicator hole line. The thermostat cover is at the top rear of the head. It uses 3 bolts for attachment. There is a bypass flow from the motor's intake to behind the thermostat. I reasoned that if this bypass was there to relieve pressure buildup before the thermostat opens, that I could tap into it and not make any change in the thermostated cooling of the motor itself.

I had done this modification before on a 1972 6 hp motor, so I pretty well followed that idea here.

| Water passage thru this motor |

|

This model thermostat cover was slightly different than the 6hp you take this thermostat cover and there was less room above because the upper cowling was smaller. On the top side at the same location that the bypass enters from underneath, you can then drill and tap for a 1/8" pipe tap, USING THE BYPASS HOLE ON THE UNDERSIDE AS AN ALIGNMENT GUIDE. DRILL FROM THE UNDERSIDE, CENTERED IN THE EXISTING ROUND RECESS. As these pipe taps are tapered, you can get by with only tapping it just until the tap exits the bottom of this cover plate. This cover is so thin at that location that you possibly can not get enough material to give more than a couple threads for the new outlet Ell. But because of the lack of upper clearance, you will need to remove the top raised ridge in the area of your new hole so the Ell can be screwed as deep as possible.

Now you can screw a 90 degree pipe elbow (it is best to purchase an OMC Ell #321886) which are made of nylon, which are recommended as they are more forgiving if you need to tighten more into this hole and add rubber tubing to the starboard side then drill a hole in the lower rear cowling for it to exit.

When the Ell is fully tightened and with the outlet pointing in the direction as seen in the RH photo below, you will probably have some of the threads protruding below the bottom of this cover plate. File this excess off. Now since you are tapping into the overflow channel, you will need to reach in with a Dremel tool and remove a bit of the threads to allow early warm water to exit the motor before the thermostat opens.

For the hose, I have found that automotive windshield wiper hose works great.

The photos below are taken off my 6hp article, but are so near the same that the principle is there.

| Shown here is the thermostat with the cover removed & you can see the bypass water inlet hole from the block just forward of the stat | Location of the new fitting showing the threaded Ell on the bottom inside of the thermostat housing cover using the existing water channel entrance as a drill location |

|

|

Unforeseen Problem After Overboard Water Conversion : One thing I found after this project was done was that now the upper cowling would not seat far enough down for the to latch to function. It appears that this Ell now just happens to sit exactly under one of the 1/4" bolts that attach the lifting lip to the motor cover cowling. This one was worse than on the 6hp. What worked for me was to purchase a 1/4"X 20TPI X 3/4" FLATHEAD stainless steel bolt, then countersink the fiberglass at the hole to accept the taper under the flat head, allowing for the head to now be even with the fiberglass, you may just have enough room for clearance. If not, then the latch bar that is attached to the lower cowling can be adjusted to allow the cowling latch to be closed.

| Rear view of the placement of new pee hole elbow & overboard water tube line from the thermostat housing to the lower cowling |

Note the new

countersunk flathead screw on the left needed for clearance of the new Ell fitting. |

|

|

|

Motor Mounting Clamp-Screw : The two clampscrews that hold the motor to the transom WILL need service occasionally. The pivoting handles of these screws should have oil placed on the pivot pins from time to time to keep them from seizing up, then breaking off. To service these screws, it is best to remove them from the bracket. There is a smaller screw that comes in from the rear and is screwed into the rear of the main clampscrew, holding on the large cupped washer in place. Use a 7/16" socket wrench to remove this smaller screw, then you can unscrew the clampscrew and totally remove it from the front of the bracket, clean, grease and replace.

If the screw comes out hard enough to gall the threads in the bracket, you may need to run a 5/8 NC (National Course) tap in to clean up the threads. Try to preserve what you have, because you can not purchase new just the handle, but the whole handle, bolt and clamp washer for a mere $75 EACH.

Motor Mounts : There are no real motor mounts on this motor as the rotating pivot shaft takes up all the thrust and with this small a motor there is not a lot of thrust on the mounting clamps.

Tilt Lock : This motor has no actual tilt lock, but just a fiction fit on the tilt hinge bolt.

Gearbox : There is no gear shifting, so just a simple set of bevel gears are in a modular cast gearbox with a removable rear propshaft bearing plate. This appears to be one of the first to get away from the old two piece horizontally split gearbox as seen in the photo below.

To remove this lower unit (gearbox) from the exhaust housing, remove the four 1/4" size (3/8" head size) bolts from the bottom side of this unit where it bolts to the exhaust housing. WARNING, in all probability these bolts will be seized and if you unknowingly think they are starting to unscrew, THEY WILL BREAK OFF. Looking at the lower part of the exhaust housing above where these bolts are located, you may see some slight holes. This will be the location of the bolts. It may be best to soak these recesses with a good grade of penetrating oil for a week or so, hoping to elevate the chance of any bolt breaking. If not then you will be in for the task to remove these broken bolts, while saving any threads in the housing, (Not An Easy Chore).

| Side view of the lower unit/gearbox showing the water pump setting on top and the water intake slots |

|

There appears to be a change

in this gearbox in 1967, therefore many of the earlier versions, parts

may not be available. The one thing I see by comparing parts

illustrations between the years of production, it seems that the prop

shaft seal may have not been the best of design (probably not a large

enough OD). So in 1967 they changed the gearbox head and seal

and discontinued the head AND seal. I suspect the new head and

new larger OD seal will interchange with the earlier

versions (again my guess). However the only motor I have

had experience was a 1965, so have no later one to measure. By

measuring, I mean the diameter of the prop shaft. The 1965 and

66 have a 1/2" dia. prop shaft. IF the later ones use the

same size shaft, then possibly the later head should work. Also

the prop nuts are different, (the earlier ones being obsolete) which

causes me to question the above.

The drain plug washer does not show up in the parts list for the

1965-66 motors, but #0311598 does fro the 1967s. Why would they

change that???

Seen in the photo below are two silver colored dime size threaded in plugs, with the words Oil Level above the upper one. The other "Fill" plug is on the lower edge of the radiused gearbox. You remove the upper one, then remove the lower, quickly insert the gear oil fill nozzle and squeeze oil in until it runs out the top hole, which is the proper amount.

Now again looking at the photo below, line up the part you can see of the driveshaft above the water pump, and visually extend it into the gearbox. It comes out nearer the front than the rear, and to make it as simple as possible, the driven gear on the propshaft is rearward of the drive gear on the driveshaft. This would in normal shifting type gearboxes be the reverse gear that is being driven. Therefore these props have Left Hand blades.

| Side view of the lower unit/gearbox showing the water pump setting on top and the water intake slots |

|

|

Water Intake : These motors main water supply to the water pump comes from water intakes are on each side of the rear of the gearcase housing, in front of the prop, so when the prop is spinning, it is sucking water past the intake holes.

Water Pump : This original Impeller #277181 and was replaced by OEM #0777819, and again by #0434424 is for metal pump housings. If motor has a plastic housing use impeller #0763735 instead. Impeller dimensions are approximately: .500" thick, 2.700" diameter, shaft OD .440". This tells me that the early versions used the pot-metal water pump housing.

Prop : The prop uses a shear pin 1/8" (.125") diameter X 1.250" overall length. These pins appear to pretty substantial and I doubt if they would break before a blade on the prop would. This motor uses a LEFT HAND 3 blade aluminum prop in 8" X 7 1/2" size and has a 1/2" prop shaft hole. I can not find a part number on it, only the size.

These props had the drive pin forward of the rubber drive hub, with a threaded hex nut on the rear. This nut had a circular groove in the center of the hex where the cotter pin can be pinched over and into. Forward of the nut's hex is a 1/8" turned down section for the rubber cap to snap over the complete nut and cotter pin to retain it.

Prop Shaft Seal : This part is factory discontinued for the early 1965 - 1966 motors.

I still have the 1965 motor used for this article, and in measuring the shaft and approximate OD of the seal while still in the housing, I get about ½” x 7/8" (.875"). In looking up these dimensions for "radial shaft oil seals" on an large industrial supply company, I get .500 ID X .875 OD X .250 width, which appears to be a pretty common seal size. But there are about 3 lip variations, If I was buying one, try to get the double lip version. For those of you who are too lazy to go to your local NAPA store and let them come up with a part number and order it for you, you can go to https://www.mscdirect.com/ or 1-800-645-7270 and order #36676203, which sells for $7.99.

The numbers that I took off my seal (while still in the housing) are CMC 736 7624., but without a cross-reference book, I can not relate that to a National or Brazo brand part #.

| Rear view of the lower unit/gearbox showing the 3 blade prop & nut, with rubber nose-cap |

|

Prop Shaft Nut : The 1965 and 1966 #032236 prop shaft nuts are obsolete. 1967-1968 uses #0203829 which sells for $35. Shown below is a CAD drawing of the early obsolete nut and washer.

| Here is a CAD drawing of the prop nut & washer. |

|

In Summary : The gearcases of these early motors appear to be somewhat of an orphan, therefore 50 years later, if there appears to be any chance of a problem, shy away from them if you are a prospective purchaser.

Copyright © 2014 - 2022 LeeRoy Wisner All Rights Reserved

Back to the Main Ramblings

Page

Originated 11-24-2014, Last updated

06-23-2022

Contact the author

1965 Johnson 5 HP Prop

shaft nut

0322236 : Replaced by 0772577 1965 LD-10 obsolete, NLA

??????? 1966 LD-11 NLA not listed, wrong part

203829 — NUT,PROPELLER $35 1967 LD-12

203829 — NUT,PROPELLER $35 1968 LD-13B

203829 — NUT,PROPELLER $35 1968 LD-13E

203829 — NUT,PROPELLER $35 1968 LD-13M

-----------------------------------------------

#12 Impeller #277181 (replaces OEM #0777819.

If application has a plastic housing use impeller 0763735 instead.

0434424 is for metal pump housings.

Impeller dimensions are approximately: .5" thick, 2.7" diameter, shaft

id .44"

Evinrude Johnson OMC Impeller & Key 0434424 is equivalent to parts:

#37 Drain Plug washer ---- 1967 0311598 - Drain Plug Washer

#29 prop shaft seal

0310328 NLA

#27 gearcase head O-Ring 0310327

#28 gearcase head NLA -- 0382586 - Gearcase Head used in: 1967 Johnson

5 HP (Model LD-12)

#25 prop shaft & bushing Assy 0381042 -- 0381042 - Prop Shaft And

Bushing Assembly used in: 1967 Johnson 5 HP

#26 front prop shaft bushing

If your impeller does not rotate with the shaft, the key that locks the 2 together is missing between the impeller & shaft. The impeller is supposed to be tight & offset in the upper part of the pump housing. To get it back into the housing, you will need to rotate the impeller as you force it in. Two ways to do this is (1) best would be with the impeller on shaft & key installed with the housing upside down so you can see what is happening (a bit of Vaseline may help) rotate the direction the motor will be turning (Clockwise looking down or CCW looking from bottom). Rotate as you force the impeller vanes in, they should all be pointing the same direction. Be careful to not slide the impeller on the shaft so far the key dislodges the impeller or from the slot in the driveshaft. (2) would be install the impeller in housing, then push driveshaft in from bottom trying to push the impeller sideways enough to get the shaft aligned with the upper sealed part of the housing. Stop the driveshaft just short of where the shaft keyway is. Install the key in shaft & rotate until the key & slot in the impeller allows the shaft to be slid the amount that the key will still be in the impeller.

Now turn it right side up & slide the lower end of the shaft down into the gearcase to where it bottoms out & you can then realign the pump housing to fit the holes in the housing to bolt it back on.

When in. some of the vanes will be compressed more than others. This is what pumps the water in thru the more open vanes & when the shaft & impeller is rotated, the water is forced out because these vanes are now compressed to the inside of the hole.