|

|

Maintaining Johnson/Evinrude 9.9 & 15 hp 2 cycle Outboards 1974–2007 ( Carburetor / Fuel Pumps) |

|

Note -- some of these articles have pictures that require a possible long load time, especially if you are on a dial up connection

Items Covered Here : This section will cover all the 2 cycle 9.9 and 15 hp carburetors, carburetor timing along with fuel pumps, but keep in mind that there may be a few slight differences depending on the year of manufacture or whether there has been an upgrade made on the motor.

This article covers all the 9.9/15 hp motors, however the main difference between the 74-92 series and 93-07 will be the access to the carburetor. This being, the later series manual starter was top mounted on the top of powerhead, and it has to be removed first by the 3 bolts holding it to the powerhead. The tricky part in removing this starter is getting the wire linkage to the "start in gear block" worked up through it's hole in the starter housing, and then reconnected later .

Carburetor Air Intake :

The carburetor cover is held onto the carb by

4 screws from the top of the black plastic

carburetor intake cover (OMC calls it a silencer). This cover made

with a intake horn to the LH side looking forward. For those of you

who may have to give the motor a slight boost if it has sat for a long time

and need to spray a bit of starting fluid in, this breather/silencer/horn is the place to do

it. But remember that starting fluid has ho lubricant as compared to

your mixed fuel, so DO NOT use this for any sustained running.

This horn will also be the location if you are winterizing, or decarbing the

motor. However you could also simply remove the cover and have access

more directly into the carburetor.

Carburetor : Do not think that you can up the horsepower by simply modifying a existing 9.9 carburetor by replacing the main jet with a 15hp main jet. All you accomplish is that the engine is being fed too much fuel and not enough air to properly mix with it, the engine will then blubber (floods out) at the top end. It may even blubber and die. The spark plugs will usually be wet and fouled. It may run OK up to about mid throttle range and idle OK, but it will have less top end power than with the original 9.9 main-jet. This could possibly also be a problem if you ordered a carburetor repair kit. The factory only lists one kit for both the 9.9 and the 15hp motors. If they include both main-jets in this kit, be sure to install the proper one for the 9.9 or for the 15hp that you are working on. If in doubt compare the hole sizes from your existing carburetor, with the larger hole (more gas) for the 15hp.

Believe me as to the above, as I

have been there/done that. Matter of fact that is what years ago got me

into writing the original of this article so I could document and remember myself,

as I could not readily find any factual information on the subject, only

speculation from so called experts. To reiterate the above, a modified 9.9

carburetor using a 15 hp main jet WILL NOT work, (BEEN THERE, DONE THAT) it will

run, but less power than it was with the original 9.9hp main-jet as it will have too much

fuel for the air ratio and the motor will be blubbering all the time at higher RPMs

and it will not achieve even the same speed as with the smaller main-jet.

Factory

specification rating for HP in relationship to RPM of the 9.9hp is at 5000

and the 15hp at 5500. With operating

range for the 9.9hp at 4500 to 5500 RPM, and the 15hp at 5500 to 6500 RPM.

Also there is a neoprene seal on the outer part of the idle jet shaft (buried into the casting body) that needs to be there otherwise there will possibly be air pulled in around the threads. There is another plastic needle "bearing" that is inset into the inner part of the needle recess that the front of the needle goes thru that acts as a front bearing to align the needle to the seat. This bearing usually stays in place, however if it does come out, just slide it onto the unthreaded front part of the needle and reinstall. Trying to remove this bearing is about impossible.

On some of these motors, you may find that the starboard carburetor nut is buried and does not give you a lot of room to get a standard wrench on. Most 7/16" wrenches has a handle so long that it is stopped by the outer side of the lower cowling. Shown below is a modified a 3/8" wrench that was ground out to fit 7/16" that the wrench angle seems to fit about all models that I have found.

| Modified carburetor wrench |

|

|

Difference

Between the 9.9 & 15hp

:

When they designed this series of motors, they designed it as a 15 hp

and then detuned it with a different carburetor for the 9.9.

When the 9.9hp and 15hp came into being in 1974 and up

thru 1978, the only real difference between the two motors was the carburetor. In

1979 they added a shim, part

#325038, (one for each cylinder), behind the leaf

valves and under the stop plate for the 15 hp, apparently to allow leaf valves

to open up more at higher RPM, giving the motor more fuel in the air mixture.

The owners manual indicates that the operating range RPM for the 9.9 to be 4500 - 5500 where for the 15hp it is 5500 - 6500 RPM. So where the 15hp gets it's power over the 9.9 is that the carburetor allows more fuel/air to increase the RPM by 1000 which equal the extra power.

It is my experience however that the 15 hp does not idle down as slow or as smooth as the 9.9 hp does. It should not really make that much difference as at an idle they use a different idle jet than the main jet, except that the 15 has a larger throat size and apparently needs slightly more fuel even at an idle (trolling speed). So if you intend to troll for trout at a SLOW speed, you may want to stay with the 9.9 carburetor, however if you want it for a backup motor and salmon troller (which usually requires a slightly higher troll speed) then consider the 15 hp. The change to aftermarket Boyeson reed valves may help in this situation however.

The outside visual dimensions of both carburetors appear the same, unless you look INSIDE the throat from the front. If you look in from the rear, you will have to position the throttle plate to a horizontal position to be able to see the throat very well. The 9.9 hp carburetor’s INTERNAL THROAT is .625 dia., 15 hp internal throat is .875 dia. up until late 1987 when they went to a plastic topped carburetor. NOTE this is not measured from either the from or back but the internal throat that you can see on the LH photo below. The outlet or rear throat dia. is the same on both (.994") to match the manifold port dia. The idle jet venturi system is also slightly different between the two. The part number for the the pre 1987 9.9 hp Carburetor Assembly is #388936, while the 15 hp Carburetor Assembly is #338273. This increased throat dia. and larger main jet allowed it to breathe better and to pull more fuel in, increasing the RPM about 1000 RPM, hence more HP.

For those of you who think you are a good machinist and

can bore out the throat of a 9.9 to make it a 15hp, well NOT REALLY.

The throats are made different, you may be able to take MAYBE ¼ of the

needed diameter, but would you get any noticeable gain? Then the

mainjet tube from the float chamber up thru the center of the throat and

into the upper section is different on the 15. And I have NEVER been

able to remove these tubes without ruining them (or getting so close to it

that I gave up), so without being able to do that, you could not bore it

out.

| 9.9 on left & 15 hp on right as viewed from front, & with choke open, notice the internal throat size differences | 9.9 on right & 15 hp on left as viewed from rear, but with throttle plate closed & you can not tell any difference |

|

|

|

The photos below show the differences in the carb throats. In the RH photo, looking in from the front behind the choke, the light blue is the throat size for the 9.9 hp, while the dark blue represents the 15 hp carburetor, represented by this CAD drawing of pre 87 carbs. The one on the right was snatched off the OMC 9.9/15hp group board on the internet. Considerably more air flow. In redneck terms, the 9.9hp will be about the size of a nickle, while the 15hp will be closer to quarter.

| Here are the differences, CAD drawing of a pre 87 carb. | Here, a close up view showing the difference in the throat diameter |

|

|

A

problem in buying a used carburetor is that the part number may be hard to read

as it is only stenciled on. And many people, even marine mechanics, do not see enough of these to

be really sure which is which unless they see them side by side. The reason for this is that when these

motors were sold new, say in 1978, the 9.9 went for $647.75, while the 15hp was

about another

$150. Needless to say way more 9.9's were sold than the 15's by possibly

80%, therefore considerably less used 15's parts are available.

FYI, here are the specs on the carburetor mainjet/orifice = 9.9hp Part Number 321742 - ID Number 40 - Orifice Size

0.040 inches - 5/16-24 thread size, 15hp Part Number 322293 - ID Number 54 -

Orifice Size 0.054 inches - 5/16-24 thread size. Either one will screw

into the other body, but will not function unless the throat size is correct

for the HP. BEEN THERE - DONE THAT early on in my learning experience.

If you

do decide to up you HP by changing to a 15hp carburetor, try to stay in as

close a a year range as possible because there were changes in the carb arm

cam roller diameter. As the replacement carburetor you get may

have a different size roller, you will have to "link and sync" the carb roller to

the timing plate, otherwise you may not achieve the high end performance

that you

anticipated. Or swap the carburetor roller arm assembly off your 9.9

to the 15hp carburetor.

Carburetor, Early Metal : Early production motors had all metal carburetors including the fuel float bowl. Then from about 1980 to late 1987 the same basic carburetor as previously was used, but had a black plastic bottom fuel bowl. This plastic seemed to be an improvement in that if water had entered in the system and got trapped in the bowel, then sat for a while creating RUST inside the carburetor, even enough rust on the outside if used near saltwater to corrode holes in it. If you have to replace the metal bowel the cost was $24.00 as of 2005. I have however seen metal fuel bowls on 1982 to 1987 carburetors, however I am not sure if the carburetor was ever changed or just the bowl. Or there may have been a supply of metal bowls on hand on the dealer's shelves if the plastics had gotten cracked?

The older floats are made of varnished cork which can get deteriorated over time, especially now with the Ethanol fuel, and may not function properly, if so replace it with the newer black plastic type.

If the float bowl gasket on the carburetor is black, it is the older composition cork material used for bowl gaskets, the float will usually be cork also, then you are probably way overdue for a overhaul. There could be pieces of this cork gasket floating around inside the bowl, occasionally plugging the main jet. The float should be OK unless the varnish has deteriorated.

On the early carburetors which used all steel float needles, the little float needle valve clips did not exist then. They have become necessary because the modern soft tip needles can stick shut.

You may see float needles used a nylon tapered tip for the actual shut off seal even on the early production 1974 but these may be replaced parts over the lifetime of the motor.

When ordering carburetor repair kits for these older carburetors, you will find a small white Nylon funnel that is actually a needle bearing. Somewhere along the line early on, the carburetor was apparently redesigned internally to better support the needle. So your carburetor may or may not use it, in any case you can not see inside well enough to tell if one is there or not, and if one is, how do you easily remove it without damaging the metal carburetor, so I simply do not use it. And it is not shown in the illustration below as #21 is the outer rubber needle thread seal.

These older metal topped pre 87 carburetors idle jet needle is 2.500" Over All Length, as compared to the later plastic topped needles as shown below in that section. The body of these needles were made of brass while the tapered needle itself is made of Stainless Steel. The straight (front) steel section is .092" diameter and is .300" long. The tapered needle part begins at the rear edge of the straight part but is .063" diameter, tapering a distance of .240" farther back to it's terminal end of .028" with the end being flat. Overall length of this steel section is .530". The overall diameter of the brass threads are .250" with a thread pitch of 28 TPI, with the smaller brass diameter of .156" to where the stainless steel is permanently inserted.

| Here is the idle jet needle of the 9.9 & 15hp metal topped carburetors #22 in the illustration below |

|

|

| The illustration below is a OMC carburetor from 1974-early 1987 |

|

In the LH bottom photo, you will note that the cam roller pivot arm is white plastic and with an adjustment screw. This would have been a later unit in that series because the early arms were made of steel with no adjustment. Some of these carburetors are missing the throttle cam roller and arm unit.

|

Carburetor, 1974 to 1979

|

Carburetor, 1980 to early 1987 plastic fuel bowl |

Late 1987 to 1992 with

|

1993 to 2004 |

|

| RH VIEW |

|

|

|

|

| LH VIEW |

|

|

|

|

Carburetor, Late : One thing to be careful is when reassembling these plastic topped carburetors, DO NOT over tighten this plastic cover, as you could break it. There are numbers cast into this plastic top that indicate the sequence of the tightening of these screws.

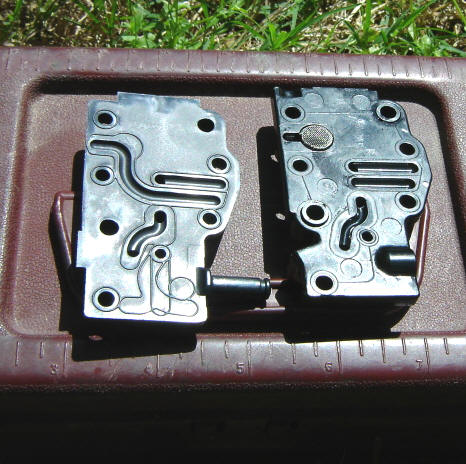

Late 1987 and newer production carburetors up thru 1992 were completely different, had the bottom fuel bowl and top made of HEAVY black plastic. The choke lever is the same in these newer carburetors even though the motors used the cable twist grip which utilized a totally different throttle system.

You will find that during this time-frame and later, that the factory was playing /trying to somewhat standardize with carbs. Apparently the bodies used the same castings but had different throat size for different HP motors from 5 to 20hp, but the covers were interchangeable (somewhat). There were considerable top numbers dropped or superseded, ultimately trying to utilize one or two different covers for many motors. What I have found is that the carburetors up to and including 1992 used 5 screws holding it down, the 93 and later uses 6 screws, with the 6th on the left rear by the roller looking forward.

Also for the 9.9/15hp carbs up to and including 1992 the idle adjustment screw came in from the front of the carb allowing the adjustment to be made from the front of the cowling. The 93 and newer used a rear side idle adjustment screw that required the upper cowling cover to be removed to make adjustments. Other models (6 and 8hp) went to the rear adjustment a few years earlier (1988). Many of these plastic tops were cast with provisions for either screw location, depending on the final machining, as some had the boss cast at the rear side but not threaded. Later ones were both threaded, which made that top more universal. However it seems that there was a early top and a later top. The early top rear idle screw location was at an angle rearward. The later tops rear idle screw location is 90 degrees to the carb body. The front idle needle for the early top is too short to function in the later top.

The covers that had both idle positions threaded, were designed to use either of the needles (front or rear) but only one or the other. The cover had provisions where both needle passages assessed passage into the same passageway in the top, which in turn led to one hole in to the aluminum body. Just plug the unwanted hole depending on the model.

The late replacement top covers are made of a different material. The early covers in addition to the 5 screw holes, had two larger holes at the location of the metal that held the choke rod. Here there was a plastic standoff that went into these larger holes. This was slightly longer than the thickness of the top, apparently to not have any extra pressure on the top when the breather was screwed down. The late replacement covers eliminated these two larger holes, but added raised bosses so that now those breather screws also help secure the top. In addition to these interchangeable tops, the gaskets also could be different, diverting air/fuel differently as needed.

In the float chamber here is a white nylon collection box that is sandwiched and gasketed between the main body and the bottom fuel bowl that has a removable main-jet on one side. These carburetors appear the same for the 9.9 and the 15 hp with the exception of the main-jet AND the throat dia. in the main body. In the parts list, the main-jet for the 9.9 is spec'ed out at a hole #34 (.055dia), while the 15 is #54 (.110 dia.). The idle jet suction tube comes off this collection box and goes up into the plastic top for suction to the idle jet itself. The inner hole here is rather small so the fuel needs to be clean. However this arrangement appears to help keep debris out of the jets.

The choke butterfly is the same as the previous models, but the throttle plate is smaller. The internal throat of the 9.9 is about .500 dia. while the outlet hole into the manifold is .750 dia. This is quite a bit smaller than the earlier versions, with the guess is that this newer carburetor is probably more efficient. It appears to have all the screw holes and outboard fittings in the same locations, but whether it would interchange with the earlier versions and function reliably is something I have not tried, but I suspect it would function OK. However some of the the internal castings of the intake manifold appear different also. OMC repair kit #439073, or NAPA /SIERRA part# 18-7219.

IF it is more efficient, then the motor will possibly idle better and have less of a black oily residue ooze out of the lower part of the exhaust housing for weeks after it is put into storage. One other observation while the carburetor is off, you will notice the intake manifold has a slight vertical separator on the bottom section up about 3/16". The supposition is that this may help fuel flow to the individual cylinders better. These later carburetors also had an adjustment screw for the cam follower.

Both these older and newer style carburetors up to 1992 use the same air box or silencer, but to most of us it is known as the air breather.

If you see a carburetor advertised on e-Bay that does not have the above RH side choke lever, but only a shaft protruding with a roll pin installed, it will be for a 1993 or later motor, as the choke lever is different.

There then was another twist that you may encounter and that is a remote controlled motor that has a electric choke. On these there is a small solenoid with a wire running up to the choke lever on the carburetor for activation when you hit the remote choke button.

| Illustration of exploded view of late plastic topped carbruretors |

|

Also in the newer plastic fuel bowls you can see a drain plug threaded into one side of this plastic bowl. There may also be another boss on the opposite side. This could because these parts seem to be as universal as possible, fitting many different carburetors. And some of these motors do not use a choke, but a fuel primer, if this is the case, this second boss can be tapped and act as a fuel supply for the primer instead of teeing off of the carburetor's fuel inlet line. These primers inject raw fuel into the rear of the carburetor and behind the high speed butterfly.

Update Carburetor Top Cover : There seems to be a lot of unanswered questions on this subject. Repairs for some of these carburetors can be confusing and expensive. This can get confusing and I may be adding fuel to the fire, but here is what has been found.

The new style black plastic topped carburetors used on motors made from late 1987 to 1992 had a habit of the plastic cover warping or cracking. The crack begins near the front hole for the idle needle jet and running along the top of the cover over the needle cavity. Warping also occurs at the middle rear. Either could allow air into the idle circuit making for a rough running motor. This could also contribute to a hard cold starting motor.

The factory came up with a reinforced top cover to rectify this situation. The fuel circuit on the new cover is different from the older cover and the gasket that fits between the cover and body is also different. The older covers can be identified by the pivot for the throttle cam roller, with this pivot being a metal screw that screws into the port side of the plastic top cover. The later update covers utilize the pivot post as being integral with the plastic top and use a retainer washer held in by a O-Ring for the roller arm as shown below.

The early hard plastic covers used a threaded screw as a pivot for the cam roller. If the throttle linkage was not adjusted correctly, at the high speed end of the throttle/cam range the cam could place undue/excess pressure on this screw, cracking or even breaking the threaded boss as seen in the cover on the left. This particular cover also had the threads pretty well obliterated. You will see the white nylon modification and JB Weld on the top. The rear idle screw boss is not threaded on this one.

The middle cover in the left photo below, both idle screw locations are threaded, but it still has the threaded cam pivot screw. You will notice both this cover and the one on the left have bosses with larger holes which use internal pillar posts that the choke plate is secured down by. The middle cover is missing both pillars, while the left one still has one in it.

There is another cover not shown below between the middle and right cover that would be the same as the middle except would utilize the integral plastic post as the late replacement top on the right. But you can tell the right cover in the left photo below is a late replacement because of the 90 degree rear idle boss, but not threaded. You will also notice no two large choke pillar holes. Also the texture and color is duller than the older covers. The thickness is thinner, but the bosses are raised at the 5 screw holes to compensate allowing the original screws to be used. The large center raised portion is eliminated, possibly to allow for more flexibility of the rest of the cover and there are braces out to the pivot peg.

And I suspect there is still another cover earlier than the one shown on the left. This one would possibly been used before they decided to change and add a idle jet at he rear so could be made without that boss.

The cover on the right photo is a late replacement for a carburetor that uses the rear idle screw, where you can see the plugged front location.

On the bottom of the covers there is a slight raised ridge around the holes or passageways which provides a better seal than if the cover was just flat.

The post 93 covers used 6 screws with the 6th one going into the cover in the location of the round flat topped boss at the base of the pivot peg as shown on the two covers on the right in the photo below. Again it looks like a chance to utilize one cover to fit many carburetor bodies.

And then the post 93 plastic float bowls are the same as the pre 93, but also have a drain screw or primer choke fitting on the RH side.

| Transgression of carburetor top covers, top view | Late top cover |

|

|

Shown in the photo below is the same tops as above, with corresponding gaskets but from the a bottom view. The photo on the right shows the early and late idle jet needles. Note the late needle is longer. The threaded body is the same 1.980", but the late needle itself is just over 1/8" longer. Actual overall dimensions for both are, the early 2.770" with the late being 2.888". As a reference, the older metal topped pre 87 needle is only 2.500" OAL.

| Carburetor covers with gaskets, bottom view | Early & late needles |

|

|

It appears that if you have a early plastic topped carburetor cover and are having problems, by all means protect what you have as it will get expensive to convert to the new conversion kit. Do so even if you have to JB Weld things back together.

The repair kit lists as being for, 10/14 hp 87-91, 10/15 hp Commercial models to 87–92. And 9.9/15 hp recreational models 87-92 using a carburetor with separate black cover (original part # 0331735 (superseded to 0433973) .

Now to confuse things, the parts catalogs lists a early and a late carburetor, but does not describe the difference NOR where the serial number break between the two is. The last letter of the motor's model number tells them the series or modifications. Probably the only way to truly ID these would be to call the parts supplier and provide them with the COMPLETE motor model number or the carburetor part number if available. In one online parts supplier the later unit was listed as fitting a code number "N". I have a 92 that is a code #A, which I assumed is an early version.

You will note that the current BRP catalog shows kit #0433973 ($34.00 as of 2007) ($99.97 as of 2013) as a kit and fitting the EARLY carburetor which includes the cover #0336049 (discontinued and superseded to #0337833 $12.99, gasket #0334043 $4.08, late needle #0435356 $25.99, needle seal #0315232 $4.99 and cam follower washer retainer O-Ring #0321117 $1.05. Is my math wrong here as these parts are about 1/2 the price when compared to the price of the kit?

Now, I will comment that my 1992 motor had never had a problem of the top warping or cracking at the needle, and it has the older style screw type pivot shaft. However in it's previous years it appears that someone screwed the pivot shaft in too deep, breaking it off behind the screw boss. This break was not into any passageways and JB Welded back together. That lasted for who knows how long until I was having a reduction in high speeds. In investigating, I found the roller sleeve was broken and 1/2 of it missing. Ordered a new roller assembly and when I got into it, found that the internal threads in this cover where the pivot screw goes into was almost all stripped out, allowing the roller unit to wobble. Now I found the threaded screw boss was also split horizontally, just a lot of plastic fatigue.

I made a new Nylon peg (similar to the newer replacement tops) to replace the older style pivot screw, then JB Welded everything back together. In this process, I tried to replace this cover with another newer type off a 1989 6 hp that had the rear idle needle jet. By plugging and sealing that hole I tried to use my front needle. It did not work. The motor ran and idled down decently, but no matter how much I tried to adjust the needle in or out, it ran the same, so I had to assume the covers and needles need to be matching each other, with my needle being shorter.

OK, I bought the late cover #0337833 at $12.99, which fit, BUT my old needle was short and would not bottom out allowing the idle to be adjusted. I then ordered and installed newer needle gasket and needle seal, but for some reason the motor does not want to idle down like it used to no matter what I do to rectify it. Possibly because of standardization, where all these new top parts are the same for both the 9.9 and 15hp. ???

Now if you get a new needle, or even just install a new needle seal, this seal is rubber and unless you smear some Vaseline on the needle threads, (even if you do) it may be so tight, that when reinstalling the outer adjustment knob, that the serrations inside the knob will strip out when you try to adjust it. Time for a new knob also.

Now an update on this new cover utilizing the molded in plastic peg for the pivot of the carburetor roller arm. Be sure you use the right O-Ring retainer on this peg, (#33 in the illustration above). If it does not secure the arm, (or becomes broken) you will get erratic idling, hard starting and no top end speed because the carburetor arm is disconnected. If you need to replace this O-Ring, a well stocked hardware store may have them in a size of 3/16" ID X 5/16" OD.

Removal of the Carburetor : You need to remove the 4 screws from the top of the black plastic carburetor intake cover (OMC calls it a silencer). However the early ones I have seen are white instead of the common black color that is on the later versions. It just could have been that some motors that had white ones that were made of a material that did not survive vibrations as I have seen may missing. Remove the choke lever, and the idle knob. When removing the idle knob, it pulls off straight forward. Make a note as to the location where the indicator tit is pointing, as you should replace it in the same location when reassembling.

You also need to remove the recoil starter unit. The manual starter unit can be unbolted with the one 9/16” headed bolt head in the center of the recoil unit. Be very careful as that spring is dangerous! Pull the rope out a few feet and tie a slip knot in it so that it can't rewind back. Carefully remove the starter handle, then grab the rope inside at the starter pulley, then let the rope withdraw somewhat but not completely (leave a foot or so to work with). Now, secure the rope inside at the starter pulley to the upright pulley gear guide in a manner that will prevent the spring from rewinding the cord etc. Hold the manual starter assembly together when loosening the top large retaining bolt (do not remove that bolt completely from the starter housing assembly). Carefully remove the starter assembly while holding it together. Screw a 3/8" nut on the bottom of that large retaining bolt to hold the starter together while you're working on other components.

There is a small coil spring (#1 in the photo below) from the carburetor to the ratchet of the starter and up to about 1979 that needs to be unhooked. This spring's tension is released by a lug that the timing plate cam positions when the twist grip, shifting lever are in neutral. If the throttle is faster and the motor is in gear this black plastic dog drops down into the starter spool teeth, not allowing the manual starter to be pulled. This dog's function will still operate by gravity if the spring #320490 is missing, but not as positively. This spring is obsolete and only available from aftermarket suppliers at a cost of $9.95.

Commonly Lost Part : There is also a Z link rod (shown below) This ties the roller bar unit to the throttle valve of the carburetor. Do not loose it either, or a makeshift one will need to be fashioned from a piece of welding rod. The important thing here is to get the bends just right so that the timing is consistent when the timing plate moves this roller forward to give movement in the throttle valve increasing fuel flow.

In the illustration below is the dimensions for it if you need to fashion one. These appear to all be the same from 1974 up until about 1986, after that, there is a different number that has a slight "V" bend front to back.

| OMC # 312830 Link, cam follower |

|

Clean & Rebuild the Carburetor : One thing I read a on the outboard repair forums a lot is that someone used a carb cleaner on his carburetor, but it did not help. OK, there is a big difference in using a carb cleaner buy squirting it into the running engine's breather intake, OR doing a complete carburetor tear down/cleaning job. If your carburetor is plugged internally with any kind of debris, just how do you think spraying cleaner into the intake is going to do anything down deep inside the bowl/jetting? To do a carburetor repair, you need to remove it from the motor AND do a COMPLETE disassemble, soak, clean, dry, inspect, and replace parts if needed.

To get ready for this you need to remove the fuel line off the carburetor. Pulling these carburetors off the 1974 to 1992 usually require also removing the recoil starter spool assembly. The post 93 motors use a totally different recoil starter assembly and the carburetor can be removed without taking the starter off, however as easy as it is to remove, it might be worthwhile.

Once the carburetor is off, unscrew the bottom screws that hold the sheet-metal bottom pan on. When removing this pan, be careful, try to save the gasket if you are not going to get a repair kit. Remove the cross pin that holds the float, remove the float and the needle valve. You will need to also remove the idle shaft screw, tighten it lightly until it bottoms out, count these revolutions it takes before it bottoms out. Then remove it completely. In replacing it, do the same, all the way in and out to you numbers (usually 1 1/4 to 1 1/2 turns out. This way you can replace it with the same number of revolutions when you reassemble it. If the insides are dirty, you can get a can of carburetor cleaner, spray on or soak until things soften up. Usually you can use an air hose to blow thru the passages, be sure they are clear.

In the illustration

of the early carburetor above, you will notice the #26 float needle valve and seat that the needle has a small

wire clip shown. This was not on the early, (possibly 3 or 4 years of

production). Where this clip goes is, it slides into a groove in the

needle, then the other end goes over the flat part of the float pivot plate

just ahead of the pivot pin. In functioning, it ensures that the

needle is retracted when the float drops as the fuel is used. It could be

possible that if the needle were to stick up (closed), did not open to allow

fuel back into the carburetor, the motor would starve for fuel.

This float has 2 adjustable settings, one

with the carburetor turned upside

down, so the float closes the needle, the

bottom of the float should be parallel with the metal body. This is the

shut off level utilizing the float needle valve so the carburetor does not flood.

The other

setting a drop setting, is how far open it goes, allowing fuel into the bowl. There is a

tab on far rear of the float pivot metal. This tab bears against the

needle valve seat base. It is the stop for allowing fuel into the carburetor.

I have not seen any measurements in any service manuals, but by bending this

tab so when the carburetor is laying upright, you can adjust this open height

setting. I have found on most of my carburetors 1 1/4" is the setting

(longest point from the metal body to of the bottom of the float) that works

for me, however an other mechanic found in print somewhere saying 1 3/8" drop.

Now to confuse things, just measure the depth of your float bowl. I get

.900, or just over 7/8", so anything over that .900" will be meaningless as the

float can not travel over the depth of the bowl.

There is one solution that works great to soak carburetors in, it is any of the outboard de-carbonizing liquids. One that is universally available at even automotive supply stores is Sea Foam http://www.seafoamsales.com/ that is used as a fuel additive to help unstick automotive hydraulic lifters or run it in the gas to decarbonize piston rings. It will not damage any of the rubber parts. Just soak it overnight. Another solution is Pine Sol household cleaner.

However just

soaking it in cleaner is not cleaning it. The jets need to be removed,

then

checked for debris, removing any if found. The small passages leading behind both the main jet

and

idle jet need to be free of debris. Usually you can blow out these

passages with compressed air. Blow one direction, then change directions

blowing the other way if possible. But if you are unsure, read on.

It is best to remove the core plugs

on top and sides of the carburetor (as

seen by the red arrows in the photo below) to access and clean the well

area and 4 small holes (2 larger) leading from the well to the rear of the carburetor throat. To

remove this plug, gently drill a small hole through it, (they are made of thin

aluminum) being very careful not to hit bottom when you go through.

Insert a ice pick or bent nail, pry the plug out. Exposing the idle

circuit mentioned! You need to

do so, as these are the primary passage ways for the starting circuit when the

choke plate is closed and the idle passage ways when at idle. Plus

they assist the venturi system of pulling fuel through the high speed main

jet.

| Here the upper core plug is removed showing the idle jet holes |

|

Clean the cavity, then replace

the plug. A replacement plug is part of the carburetor repair kit.

To install, clean any debris in the bottom ledge that the plug fits into, locate the new plug, get a punch of just slightly smaller diameter

than the plug and flatten out the new plug to seal it in place. Go easy, but be

careful not to whack it so hard you crack something. If you do not

have access to a kit, you can reshape the plug and reinstall it, then cover the

hole and the edges and the removal hole with JB Weld.

There are other

smaller lead plugs (blue arrows in the photo below) that MAY have to also be removed to clean out

the inside IF there is no passage. However try blowing compressed air

thru the passages that it looks like these lead to/from before you remove them

as they may be OK. These are simply lead shot from shotgun shells, that

are tamped into the hole to plug it. The reason these plugs along with

the core plugs are there is because with these older carburetors, in making

the air/fuel passages make corners in the body, the drilling had to be

accomplished by drilling more than one connecting hole to make a corner.

These plugs sealed off the corner. When the plastic topped carburetors

came into being, these were plugs eliminated as the machining was all done on

the bottoms, and the plastic tops/gaskets could divert the air/fuel to needed

locations.

| The photo below is a OMC carburetor from 1974 to early 1987 showing the removable plugs |

|

With the carb upside down and the float

needle removed you will see in the center a hollow brass plug with slots in

it for removal. With that jet out, below it is another small tube that

also is slotted. This tube is pretty much NON REMOVABLE, at

least in a usable condition. It is not even listed in the parts

diagram, meaning it is not sold separately. It is a hollow tube

that acts both for the high speed fuel along with the idle fuel. Gas

siphoned up by vacuum through the center of the tube for high speed.

This tube has a few small holes drilled crosswise in it that pulls fuel for

the idle part of the carb. If you screw it up, you have ruined the

carb. You might try to unscrew it, but if it resists, leave it alone.

Here you may want to find a small drill bit that will fit inside this tube,

then carefully clean it's insides. I usually clean things the best I can and blow it clean with compressed air.

I suspect they (the factory) used a special hollow screwdriver with a driver

internally to protect the nozzle exposed end.

In the photos below the other "jet" is really the

float needle seat. It is usually easily removed.

The photos below are from off VERY BADLY corroded 1975 9.9 carb that is an

experiment on reviving it from the grave. In the RH photo the bright

ring is simply my filing the corroded surface to illustrate better the inner

nozzle slots.

| Here the main jet (orfice plug) | Here below the main jet is the nozzle |

|

|

You can possibly get by without a repair kit or gaskets if you are careful in your disassembly do not use a gasket sealer when you reassemble it as some may dry out when the motor is stored over the winter, where some of this sealer may dry out and chunks of it can get in the main-jet. Later gaskets were a neoprene type positively does not need any sealer. If it just had debris and water in the bottom, you can get by without a repair kit. But if it is gummed up varnish you will need to go farther. Check the idle needle valve for straightness of the tip, if it got dropped, this tip can get bent. If you are good, you can possibly straighten a bent one, otherwise just get a repair kit.

For the price of a $12.75 repair kit

for the early versions, while about $21.75 for the later style. You get all new gaskets, needle valve, main jet

and new metal plugs that are

needed to replace the old ones if you have to get all the channels cleaned out,

and float adjustment instructions. Note the 3 different gaskets supplied

by the kit on the right in the photo below, these would be for different motors,

so you would need to use the correct one for your carburetor. Also on the

RH photo, the manifold to carburetor gaskets have a different diameter hole, the

smaller one fits the 9.9, while the larger is for the 15hp. And count the

number of screw holes in the brown gaskets, which are 6, so these could also fit

the post 93 models.

Most carburetor kits will be made to cover numerous versions

as seen in the RH photo below.

The metal topped 1974-1986 were pretty much alike, however after about mid year

of 1986 when they went to the plastic topped carburetor, there were numerous

changes in these until that series ended after 1992. So you will

find kits may contain parts that may not have been used on ALL of the

carburetors the kit covers. Here, use the rubber gasket that matches the

one that was on it.

In 2002 these motors were changed to 4 stroke and the carburetors were changed completely, eliminating the plastic tops.

|

OMC part number 398453

Carburetor kit for 1974 thru 1986 |

OMC part number

439073

Carburetor

kit for 1987 thru 2001

|

|

|

|

When reassembling, place the float back in position, replace the cross pin. Be sure that the small wire clip is attached to the needle and the tail is over the float plate. Tip the unit upside down to check the float height. The now upside down unit should have the top of the float parallel with the now top of the housing. If not, you can adjust it by bending the metal tab that acts as a stop for the float. Be sure that the float and needle can move up and down freely, otherwise if either binds, the motor may run at different speeds depending on how much your boat is tipped to one side or the other or raised in the shallow water drive mode.

How was the rubber idle needle seal? They call it a bearing, but actually it is a seal that keeps the needle from vibrating from it's adjusted position AND from sucking air around the needle threads. Air sucks easier than gas, so too much air/too little gas equals lean condition, equals sneeze.

You probably may not have to remove the main throttle body butterfly, during your cleaning/soaking, BUT if you did, it can be installed wrong, which does not allow this shaft to move as much as needed. When re-installing this butterfly, IF you re-attach it using the 2 screws, but do so with little spring tension on the shaft, you will only get minimal movement of the spring loaded shaft. Remove the 2 screws, rotate the shaft just enough forward to position it (over center) to allow the 2 screws to again be screwed into the shaft. This butterfly should be closed when the carburetor is off the motor, but should be able to rotate the shaft enough to totally open the butterfly as when the motor is wide open throttle.

Screw the carburetor's bottom float bowl pan back together and reinstall the carburetor onto the motor's intake manifold. Remember to reattach the small spring on the starter ratchet if it was made prior to about 1982. On the later plastic topped carburetors, you will find numbers near the attaching screw locations. These are for the tightening sequence.

When reassembling the idle jet needle screw, and you forgot how many turns it was set at, a good starting spot would be to screw it in until it lightly bottoms out, then back it out about 1 1/2 turns for the pre 87 carburetors. It has been found that for the post 87s, that have the plastic top, the presetting is about 4 turns out, probably because of the finer threads on the needle as compared to the earlier needles. Tighten the top cover screws to 8-10 INCH pounds.

The repair kits shown above on the right #439073 and #431897 appear to not include the main jets. They also cover a variety of motors, that is why 3 body gaskets are included, you will need to identify the proper gasket by comparing to your old gasket as these kits fit 6 and 8 hp 2 stroke 1986-1996, 9.9 and 15 hp 1989-1996 2 stroke, and 20 hp 1991-1996. This does not mean a 6hp carburetor is the same as the 20 hp, but just that the items in the repair kit parts fit all those identified, however you may not use all parts supplied.

In rebuilding your carburetor using a kit; make sure you remove welch plug (a small 1/4" dia. aluminum plug) on top of carburetor and get the idle circuit holes absolutely clean and blown out with compressed air. This plug can be removed using a ice pick. You will ruin it, but try not to damage the carburetor body as the new plug needs to seat airtight. I have even used the old plug, by tapping it back in place and JB Welding the ice-pick hole up.

Reinstall & Adjust the Carburetor : The initial idle jet setting is for the early metal topped carburetors is usually 1 1/4 turns out from lightly bottomed out. After getting it running this idle setting can be changed after the motor is warmed up to achieve your desired idle setting.

After reinstalling the carburetor onto the intake housing, you need to reinstalled the choke knob. The choke knob shaft has a slot in the middle that the carburetor's choke lever goes into. This shaft needs to be installed with the longest length of the slot upwards, otherwise the choke lever does not have enough room to function. It also has a thinner section in the middle that needs to be on the underside as the rear part also acts as a stop. In the photo below the red arrows point to metal that retain the choke knob shaft and apply tension top and bottom on it. The blue arrow points to the actual choke arm that goes into the slot of the shaft. The breather box has been removed for better photography purposes.

| Choke Knob installed into the carburetor cover plate |

|

Now you need

to re-install the plastic carburetor intake cover (air breather).

The idle knob is next, it is the 25 cent size plastic knob that slides over

the serrated idle jet needle shaft, and is about center of the front lower

cowling. The cowling under this knob says "Slow Speed Adjustment",

which is misleading as it is really a idle adjustment.

I try to set this knob with the pointer protrusion down so I have about a 1/2 a turn either way. As it will not rotate totally around because of a stop bump on the front cowling. Even after you replace this idle needle jet in the same location as it was before tearing it down (same number of turns out from lightly bottomed out), you get it running again, you may need to fine-tune adjust this idle knob for easy starting and trolling.

| Front panel, showing choke, carburetor idle adjustment (Rich/Lean) |

|

When you get the motor warmed up and running in gear at near your trolling speed, then turn the carburetor idle screw knob (lean/rich) one way or the other until the motor changes and either runs worse or better. By rotating this knob a slight amount, let the motor run for a few minutes, rotate it slightly more in the same direction again. Doing this you are making the motor run richer or leaner at an idle (mixing more or less air into the idle mixture).

Eventually you'll hit the point where the engine wants to die out or it will spit back (sounds like a mild backfire). At that point, back out 1/4 turn. Within that 1/4 turn, you'll find the smoothest slow speed setting and the smoothest the motor will run at slow speed.

From this point, the idle could need to be adjusted again richer to provide the additional fuel necessary to accelerate crisply while under load. Test acceleration, any hesitation, lean miss, (sometimes called a lean sneeze), or cough, make slight adjustment richer on the idle and retest. Repeat to perfection. The end result may be as far as 1/4 turn richer than 'best' idle in Neutral.

You can verify this by lightly choking it, creating more fuel and less air, enrichening the mixture. The needle could either set wrong, or there is an air leak in the gaskets, carburetor, fuel line, fuel line fittings, etc. or it might be as simple a fix as backing out (rotate counterclockwise) the needle a bit more slightly richening the flow into the motor.

If you get to where you can not rotate the knob anymore, but need to turn it farther, pull this knob off frontwards, rotate it 180 degrees, push it back on, now try to twist it some more. The front cowling has a bump on the top of the knob hole, stopping it from being twisted in more than needed. But since this shaft is serrated, you can slide the knob on in any position.

When you have finished the above adjustment, pull the knob off forward, reinstall it so the pointer in the "DOWN" position. You will now have a "GO TO" position if need be, which will be discussed later.

It makes sense when shutting down the motor for what may well be a extended period of time, to disconnect the fuel line and run the motor unit it dies, using up all the fuel in the carburetor. This procedure should not be used for multi carbureted motors as IF they do not run out of fuel at exactly the same time, you will be starving that cylinder, possibly creating galling inside the cylinder because of lack of lubrication.

Setting the Slow Speed : Most of us Shade-Tree mechanics can do pretty well in adjusting the timing/carb /twist grip throttle settings for an idle by ear. However if you get into a situation where you can not get it to idle and the engine repeatedly dies, maybe you are asking a bit too much of the motor in that slow speed. And do not rely on the SLOW, START, FAST settings on the tiller handle for actual speed settings as over time, these adjustments WILL be worn and not be correct. The only real way in this case is to use a Tachometer and actually see what you are getting from the motor.

If the idle speed in a test barrel if set correctly, 675-750 RPM in forward gear, you will probably see something like 800-900 in neutral, and 600 in reverse. But if it is set it for 600 in forward and then reverse will drag it down to around 500 which is too slow for the motor to run and it will die.

Or if all else fails,

did you remove the soft plug and lead plugs on the carburetor and blow the

passages out with compressed air? I would check your spark plugs for

cleanliness, (or replace them). Or look for an air leak somewhere in

the intake system. This could be the intake manifold gasket where you

tired to reuse the old one. It could also be from around the

idle needle shaft. Is the idle needle not bent at the tip? OR,

check your compression, if it is low, (especially on one cylinder), that

could also effect low speed operation. Another possibility would

be the reed valves in the rear of the intake manifold could have debris

under them so they were not totally closing, effecting the 2 cycle operation

(unlikely, BUT possible).

Then, it could

be possible that you have fishing line wound around the propeller shaft,

creating a resistance at low speed ?? Or a dry or rusted gearbox ??

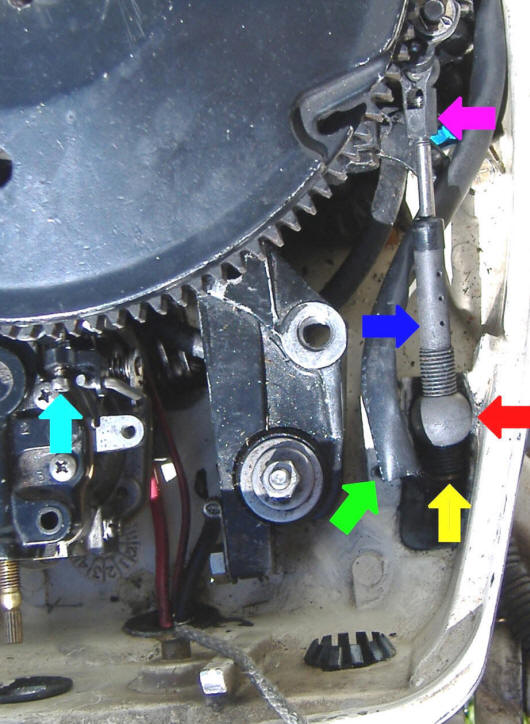

Adjust the Slow Speed Stop Pre 87 Motors : There is also a large slow speed stop knob on the left hand side of the lower cowling on all of the pre 87 motors. This large knob activates an internal threaded rod that acts as a stop for the throttle plate linkage and is used for a slow speed setting without having to be sure that the twist grip is in the same position each time you want to idle or troll, (not to be confused with the actual carburetor idle settings). This knob is rotated from the outside of the lower cowling to make contact, stopping the throttle linkage at a desired location. This shaft is shown contacting the throttle linkage at the red arrow in the photo below.

| Slow speed stop shaft limits movement of throttle linkage to timing plate. |

|

|

After the motor has been run enough to have it warmed up, try to let it idle. If it is running so slow that it dies this adjustment may be not stopping the throttle linkage arm to bump the linkage tab so you can adjust this knob stop screw on the motors left hand side. It may be best to initially do this with the motor cover off, so that you get an idea of which way to turn this screw. Turning this knob counter-clockwise pulls the threaded rod out which makes the motor run slower. Again this is not the carburetor idle jet, but a slow speed stop adjustment.

Adjust the Slow Speed Stop Post 87 Motors : After 1987 the side stop knob was discontinued when the cable throttle system was instituted. The new slow speed setting was then changed to a twist knob on the end of the twist throttle.

These can be a little tricky, and many, once they get it idling right, just leave this knob alone. First you will need to adjust the carburetor to it's best slow speed setting. The knob on the end of the twist grip is a final adjustment only.

It has internal threads which just provide a ready adjustment while the motor is running. This black knob on the end of the tiller twist grip throttle handle will rotate just over 4 complete turns. At the outermost adjustment, it wills top as the internal threads bump the outer end of the handle. rotating clockwise the threads will thread out of the internal handle threads and no more adjustment is achieved. You can test this movement by pushing in on the knob. If it has minimal movement, the threads are still engaged, but if this knob moves in about 1/8" it is out of the threads. By just reversing the rotation, (counter clockwise) the knob will pick up the threads and begin it's adjustable qualities.

I would set this knob at about one turn out from the most inward position when it started into the threads as a starting point in your fine tuning adjustments.

The throttle cable may (or was designed to, but not always will it work right) need to be adjusted so that the knob can do the final adjustment. In the photo below on the left, you will see a red arrow. At this juncture the cable threads into the ball coupler to the timing plate arm. Push down on this plastic ball receptacle end until it pops off the ball. If it doesn't come off, then you will have to unscrew the ball from the timing plate arm. Now you can thread this end so the cable is either longer or shorter.

But first twist the speed control handle to as slow as it will go. Depending on your slow speed the motor is running at, if it is running faster than your desires, thread this ball receptacle farther onto the shaft (like a couple of turns), snap it back on and see what changes were made by twisting the throttle handle. You are trying to get the motor running a tad bit slower, even dying. If this does not do it , do some more adjustment. If you don't gain anything, try the other direction. But remember how many turns you went or at least your initial starting position.

Once you think you are close, at the slowest running speed, turn the slow speed knob on the end of the handle. This knob does not have a lot of mechanical advantage, so you will have to advance the speed, then reduce it to see what gains you have made. If it is not where you want, then look at the "Throttle Timing on Post 87 Motors" in a section below as this goes hand in hand with that.

| Here, the red arrow shows the threaded adjustment on the end of the throttle cable. Shortening the cable threads allows the timing plate to rotate clockwise more allowing the motor run slower. | Type 3, cable type, red kill button on end, but with man overboard switch there also | Type 4, (1991 & 1992) cable type, red kill button & with man overboard switch farther back on side |

|

|

|

|

Carburetor Timing

: This

is many times called "Link and Sync" and will be applicable to all of the

9.9/15hp (and many others as well). The

throttle cam plate that rotates under the flywheel when you twist the twist grip

and the plate has an raised line type mark on the front of it. This mark needs to be timed so

that when you advance the throttle twist grip, that the carburetor roller is at

this mark when the carburetor throttle shaft just STARTS to turn open (RED

ARROW) in the photo below. To

adjust this on the older motors, you loosen the 2 bolts on the RH side of the plate, adjust the

cam plate to where it just aligns with the roller at the same exact time that

the throttle plate begins to rotate. For the newer motors, the plate is shown

below is made of plastic has a adjustment screw on the outside (PURPLE

ARROW). They also have another adjustment screw on the throttle cam

roller unit.

To tell when the throttle shaft starts to rotate, take a small alligator

clamp, attach a short wire to it, as if you were attaching a electrical wire

under the screw head. Clamp this alligator clamp indicator unit onto the

end of the throttle shaft (BLUE ARROW). Now

you have some indicator way better than just watching for rotation of the shaft.

The flywheel and air box were removed here for clarity.

In the photos below, you can see the timing mark by it being the lighter colored raised part at the right of the arrow's point. The older aluminum timing plates also have this same style of mark. This timing plate needs to be adjusted as the roller is just touching when the carburetor throttle shaft starts to move. On this motor, this would place it away from the timing cam plate by probably .030" at an idle.

The timing mark on the timing plate cam does not need to touch the roller at the low end (or idle) of the twist grip rotation. On these motors, at low speed, the the timing plate will move counterclockwise AFTER the carburetor cam movement and throttle butterfly valve will stop. This allows the timing to go where the motor runs at it's slowest before it would die, while not moving the butterfly valve, if the low speed side of the carburetor, (the carburetor air jet idle screw) is set right.

One thing that may make a difference in this timing is if you change carburetors, as they may not be exactly the same distance from the mounting plate to the roller pivot location, which can make a difference in this timing. Also the thickness of the carburetor/manifold gasket could also be different also effecting the timing.

| Alligator clamp indicator | Timing the carburetor throttle shaft to the ignition timing plate on a 1979 |

|

|

|

For the later, post mid 1986 motors that use the cable throttle linkage system, there are three adjustments on this cable, (1) a Allen screw on the carb throttle lever that moves the cam roller. (2) at the attachment trunion ball and (3) at the rearward end of the cable where the threaded end can be adjusted on the shaft. This end is what snaps onto the ball that connects it to the timing plate linkage.

You might have to remove pull the starter and remove a clamp that was holding the trunnion in place. There are threads on the outer cable that goes through the center of the trunion ball. By turning the ball, it travels on the shaft thus adjusting the length of the cable. That cable length change is what allows the plate to be able to rotate all the way to its proper low throttle position ultimately leading to the proper synchronization setup.

Throttle Timing on Post 87 Motors : Here we will be discussing the tiller motors as compared to the remote controls. This can get complicated because of the numerous adjustments available AND they all interact together. And a prerequisite is that you have the carburetor adjusted for the idle speed you desire.

One thing to keep in mind, once you have the "link and sync" set, no matter what the other adjustments you make, the "link and sync" will not change.

The light blue arrow at the top of the photo below is the carburetor roller "link and sync" adjustment.

To make any of the adjustments listed below, you will first need to remove the recoil starter assembly. There is a threaded trunnion ball that is secured in a pocket in the base of the lower cowling. This trunnion ball is necessary because this cable, from this ball to the connection with the timing plate connection ball is so short that the cable fluctuates up and down depending on whether it is extended for high speed or retracted for low speed operations. This trunnion ball is secured by a clamp that is held in by a 3/8" headed bolt with it's location is indicated by the green arrow. This camp has to be removed to make these described adjustments. The following information is not taken from a service manual, but by trial and error on my part, so possibly there are better instructions out there. If anyone has access to factory service manual on this, please contact me with it so I can update my info.

What all of this does is allows throttle cable adjustment to be made to accomplish more than one things. These are (and not in order), (1) adjust the timing plate to coincide better with the markings on the twist grip, like SLOW, START, or FAST. (2) give a wider range of available speed instead of being oriented toward a higher or lower setting, which if the lower setting, may not allow your motor to achieve a higher RPM. (3) prevent premature carburetor roller failure, if set to where the timing cam is pushing the roller beyond it's allowable mechanical movement capabilities. (4) and if the shaft is set so there is a LOT of idle space but limiting the high speed achievement of the motor. Therefore since I do not know factory settings, we will have to make adjustments on trial and error, until we find a happy medium setting.

There is another adjustment screw on the far end of the plastic timing plate, which is not shown in the photo below, but in my estimation, it normally will not do much benefit UNLESS you are trying to squeeze every last bit of throttle/timing out of the motor, and then that is questionable if everything else is properly set.

Under where the clamp was, you will see a 1/2" threaded plastic shaft that the throttle cable passes through. Threaded onto this plastic shaft is a larger trunion ball (red arrow) that is threaded onto the shaft. The end of the cable is threaded into a snap off coupler ball (purple arrow) end. Push this coupler ball end down enough to snap it off the ball that is attached to the timing plate. This coupler may loose it's tension to stay on the ball over time, which may then need to be replaced.

The front of the cable housing has a brass threaded end (yellow arrow) that screws into the threaded shaft (blue arrow). By looking closely you will be able to barley see the brass end ring at the tip of the yellow arrow. This needs to be threaded all the way into the shaft (blue arrow).

My method of setting these is to adjust the trunnion ball so that at the fastest throttle position, that the timing cam, at it's farthest fast position, pushes the carb roller to it's bottomed out position, with minimal, if any movement left in the roller arm, but not putting excess pressure on the roller/arm unit. You could probably make these adjustments by not totally removing the clamp and turning the shaft, (or as I did by removing the clamp and adjusting the trunnion itself). You will notice 3 evenly spaced small holes in the plastic shaft. Apparently these are for identifying revolutions.

You can test this with the starter assembly off and the clamp off, BUT you will have to push the trunnion ball into the socket that it will later be in after the clamp is installed as you are checking your adjustment.

The photo below is where my motor adjustments seem to function OK.

Also I noticed that at wide open, the carb roller adjustment screw head

binds on the plastic top, which needed to relieve a minute amount of plastic

for clearance. This threaded end can give

some final adjustment in addition to the twist grip plastic end cap

adjustment for slow speed idling. However it has been found that when

threading this Nylon coupler on, rotate it slightly upward on the outside,

(as seen in the photo below) otherwise it can become uncoupled if situation

s are slightly wrong when you move the throttle to slow position.

TIP

# 1 ; After reading all my above comments, you may

find that the indicator on the twist grip does not align with any of the

speed indicators (Stop-Slow-Fast). My simple solution here is to

delve into your fishing tackle supplies and find a sheet of the adhesive

backed lure tape. Cut a wedge shape from it and attach it to the twist

grip covering the old indicator if need be. Here I have found, let it

get warm and at an idle (trolling) speed. Attach your new speed

pointer to correspond with the Slow, or depending on the year, the section

of the rotating arrow that would be idle. Now you have a new

reference point.

You might even, use a felt pen and put a mark to what would be then be your other speed reference point where you can align the two (as shown by a mark, but I need to run it more to be able to get the marks where I want them). In the photo below, you can see the old shallow reference line. On this motor there was not anywhere close to enough take up to make this difference, hence my Red-Neck alteration. The one thing I did find was, was this tape was prone to become knocked off, so I overlaid it with a single covering of clear strapping tape, wrapped all the way around.

| Here we see the simple Red Neck repair |

|

|

Slow Speed Stop :

The deeper the trunnion ball (red arrow) is threaded onto the shaft

(blue arrow) the wider range of throttle adjustment you will find and slower

the motor will be able to idle down and be able to use the slow speed stop

knob on the end of the throttle handle.

Now you can set the "Slow Speed Stop" on the end of the twist grip as described above, which may take more adjusting.

| Here we have a post 87 cable throttle system & the adjustments |

|

The real problem that I ran into here was that with the above adjustments set so that the throttle markings, SLOW, START and FAST were aligned where you would think they should be, with the throttle roller being at a position where the timing plate mark would just start to move the carburetor roller, the timing plate was out of synchronization for maximum open throttle which would not perform a optimum high speed. My solution was to adjust it so I had my maximum high speed, which still gave me my idle speed, BUT with the throttle indicators being off (way fast like actual slow speed running was just faster than the START position). This positioning also screwed up the end of the throttle handle slow speed adjustment to where it would not function.

Remote Fuel Primers:

The models using remote control (steering wheel as

compared to tiller operation) will usually require a remote choking system,

there being two types. The early used a solenoid to activate the

manual choke butterfly. The later ones may have used a fuel pump primer,

injecting fuel directly into the carburetor throat OR into the intake

manifold. And then you may see other adaptations that may have been

added over the years, (some being inventive).

In trouble shooting these, (1) Check your electrical system to the solenoid. (2) Check the solenoid itself. On the later pump systems, if the first 2 are OK, then, check for leaky fuel lines, second, in all probability, your solenoid diaphragm (#5 in the illustration below) is bad, not allowing it to pump fuel out.

| Here we have a early electric remote primer system | |

|

The Motor Will Not Start : I also have had the ball socket (purple arrow above) become disconnected occasionally when you moved the throttle to SLOW (even after installing a new Nylon coupler). In this situation, the motor will not start, (it may try, BUT will not stay for long) as your timing plate is positioned at the stop position and no amount of fuel you try to impose will even get it to do more than try to start, but then fail again. This can tax a trouble shooting situation because you are usually looking at the other side of the motor and may only find this after doing a spark test and then maybe a carburetor rebuild which neither will improve the situation. You can not keep it running long enough to to a pull the spark plug wires to see if it is running on only one cylinder. After finding this disconnect, my Red-Neck solution was to Zip Tie the coupler to the timing plate arm.

| Here you see the Zip Tie solution for the ball coupler coming loose |

|

|

Check the Cam Roller :

While you have it apart, check the cam roller. This

roller sits on a plastic arm. The early carburetors used metal arms,

with white plastic following that. Later when the black plastic tops

came into being, the arm was also made of black plastic. Attached to

this upper arm was a roller, with some also having a outer sleeve as the

contact point. If you get erratic, non reproducible inconsistent

operations, or lack of high RPM operations, it may be of a benefit to check

this roller sleeve. Sometimes they will not rotate on the shaft, which

allows the cam to wear a groove in the roller. This roller sleeve may

even become broken as seen in the photo below, or completely missing, which

will effect the carburetor/timing, especially the higher speeds. New

part #0396236 solved the problem, I

have even seen the arm shaft where the roller or slides depending on

vintage,

become worn, compounding the above problem.

One reader had problems setting the idle adjustment. "I could set it up just perfect, then after a few revs of the throttle open and closed, the idle would be messed up again! Either too high or two low. After disassembly, I noticed a worn spot in the throttle cam roller (LH photo below), since this directly translates to tiny movement in the carburetor butterfly at idle, it makes a huge difference to the idle speed depending on where this wheel stops turning when at lowest throttle."

His situation, I suspect was that the

timing between the roller and timing plate was set slightly retarded as this

roller should not have been touching the

plate cam at an idle.

The LH photo below, with this roller sleeve broken and missing parts, the motor would not rev fast enough to put the 12' fiberglass boat on a plane that it had before.

| Worn roller on the "pre sleeve" carburetor cam roller | Carburetor cam roller sleeve rear 1/2 broken off on a 1992 9.9hp |

|

|

|

Then if you can not get the motor to return to an idle, you may have the carburetor cam roller arm return spring not engaged or the outer tail broken. Shown in the photo below, you can see the coil spring wrapped around the pivot shaft. The inner end has a rounded hook that hooks over a protruding lug on the carburetor's body. The outer end of this spring has a 90 degree bend, with the end of this spring protruding out the small hole in the outer arm plate. If this spring is reinstalled incorrectly, OR the outer tail has broken off, the roller will not remain in contact with the timing plate cam, giving erratic idling.

| Here we have a LH side view of an early metal topped carb, showing the cam roller arm return spring |

|

If you are having problems locating a start position on your twist grip throttle setting because of obliterated wording, or if you have a remote throttle, a method of locating the timing "START" position would be to advance the timing plate to where the carburetor arm roller just touches the timing plate cam, then advance it about 3/8" (9-10mm) more. This positions the timing and throttle at about the start position in the carburetor.

Intermixed Parts : One thing that needs to be pointed out is that if you change carburetors, and / or partial or complete ignition systems is that possibly the two may not really be compatible. Usually this will be where the carburetor roller can be a different diameter. If you happen to get one that the roller is smaller than the original, you will get a situation like the photo above for the "Link and Sync", where the roller does not touch the cam plate mark when it should. This would give you an engine that may starve for fuel, then hesitate before you advance the twist throttle more. And it may never achieve full power. Apparently this was a mismatched parts motor with either the electronics and flywheel OR the carburetor were off different years of motors.

In the rollers that I randomly measured, they ran from .470" dia. for the early all metal carburetors all the way up to .625" dia. for a 1992. The post 93 motors were .500" while another one somewhere in the mix was .530" dia. From this, it appears that each carb roller probably matched the timing cam for that particular motor. This is why it would be pretty critical if you were buying a used carburetor, to find one NEAR your vintage. Also if you get some slop of the roller on the peg that the roller sets on, this is normal, to provide some slight self-alignment over the whole range of it bearing on the timing plate cam.

In the photo below, the simple way to adjust this cam to match the roller was to remove some material off the inner (RH) retainer peg which drops into pockets in the metal base plate. Altering this cam allowed the cam to move forward, and to come in contact with the carburetor roller. There usually is enough tension applied by the CDI plate screws to hold this cam in place, if not then a cardboard shim may be in order. The only other solution would be to find a larger roller that could be fitted to the arm, OR a new arm and larger roller.

The only other option on this motor, since it does not have a roller arm adjustment screw like the later motors do, would be to make a new longer throttle cam follower link. But that would come down to trial and error, plus removing more parts off the motor to access this.

| Here we see the bottom side of a plastic timing cam off the motor in the photo below, with a red arrow pointing to where material was removed. |

|

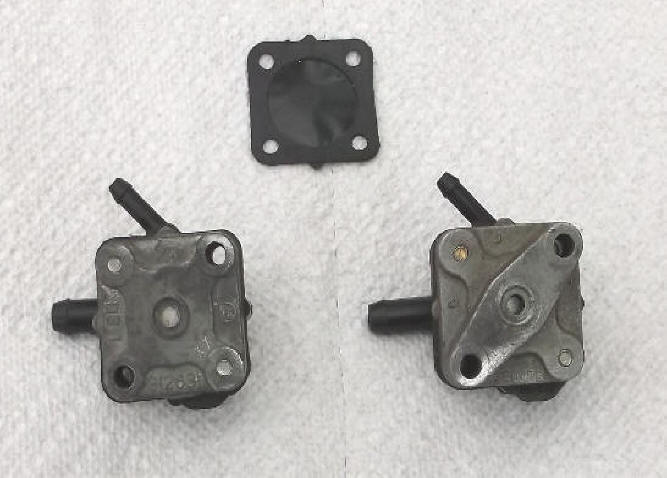

Fuel Pump Problems : The primer bulb is a manual fuel pump of sorts. It's purpose is to initially pressurize the fuel system and once the motor starts, the motor takes over using internal engine pressure, alternating vacuum inside the block to activate the fuel pump, sucking fuel from the tank. With the motor running your bulb is no more than a fat piece of fuel hose so you can expect it to be soft at that point.

Second to check would be to whether fuel is coming UP TO the motor. Is the fuel line connected to a VENTED tank. It works best if you hold the primer bulb upright, with the outlet upward when pumping it. If the check valve spring is weak, this will help the pumping by not allowing the fuel to bypass then go back into the tank. Otherwise you can hear a gurgling in the bulb as you release it. The primer bulb should become hard after about 3 or 4 pumps when the carburetor bowl becomes full and the float valve then stops the fuel from bypassing, being forced up into the carburetor flooding the motor. After the motor has run enough to remove this pressure of the internal fuel you have pumped, the bulb should become soft as the fuel flows thru it. A simple way to check if it he tank, pump bulb and line is functioning is disconnect the coupler off the motor, then use a nail, push in the small metal ball on the motor end of the fuel line coupler. While you are holding this ball in, pump the primer bulb. If fuel gushes out this coupler and all over your hand, everything is OK up to there.

A faulty fuel pump would not stop it from starting if you pumped the fuel line primer bulb up. If everything else is OK and the carburetor bowl is filled by pumping primer bulb, the motor will start, it then won't stay running (over a couple of minutes or so) once the fuel in the bowl is used up if the fuel pump is bad.

If the motor

still fails to start and the suspect could be fuel, I would then pull

the fuel line from the fuel pump to the carburetor, crank the motor over. Fuel should

spurt out of this line.

If you feel you need to test the fuel pump

pressure for these motors, the factory specs call for 1 psi @ 600 rpm, 1.5

psi. @ 2,500 to 3,000 rpm and 2.5 psi @ 4,500 rpm.

If with the motor running, you happen to have fuel spraying out the small hole on the back of the fuel pump, you have a ruptured fuel pump diaphragm. That hole is a vent hole behind the diaphragm which allows the diaphragm to pulsate, sucking the fuel from the tank. If the diaphragm itself has a hole in it, fuel is passing through that hole from the other side. It also provides a visual indication of a fuel pump issue. Under circumstances like this, your motor may run at lower speeds but appear to starve at higher RPMs. In essence it actually may have to much fuel because of the pin hole in the diaphragm, pumping fuel directly into the crankcase and since this motor is a 2 cycle which uses the suction of the bottom side of the pistons to suck the fuel in, then forces it out the intake ports of the cylinders.