|

Rebuilding the new OMC Fuel Pump

|

|

The

illustrations below are off OMC's fuel pump repair kit instructions #433519 or

NAPA 18-7800

This same basic fuel pump was used on many motors from made from about

1987 thru the current models for 9.9 hp up to

155 hp using non VRO.

However -- on the 9.9/15 hp motors

from 1987 to 1992 depending on whether it came equipped from the factory with a

electric starter or not, there was a different fuel pump. If it had only a

rope starter, then it was equipped with the older small square fuel pump, but if

it had a electric starter then this newer larger fuel pump was installed.

For these 6 intermediate years repair kit #0398514

would have been proper for the

electric start.

The pump body seems to be the same except the rear mounting plate.

Repair procedure would stay the same as shown below however.

NOTE -- These 2 illustrations are

from scanned pages from the original repair kit.

|

This repair kit is for 1990 and newer 9.9 thru 155 hp model Evinrude and Johnson outboard motors without the (VRO) Variable Ratio Oil Injection System.

Some of the parts in this kit are not used in some applications. Discard the extra parts.

(1) Contents of Kit

| Ref. |

Part Number |

Name of Part |

Qty |

| 1 | 335334 | Check Valve | 2 |

| 2 | 318375 | Air Dome Support | 1 |

| 3 | 328779 | Housing Gasket | 1 |

| 4 | 332678 | Diaphragm | 1 |

| 5 | 328777 | Cover Gasket | 1 |

| 6 | 332694 | Vacuum Housing Cover | 1 |

| 7 | 319822 | Large Cover O-Ring | 1 |

| 8 | 324660 | Small Cover O-Ring | 1 |

| 9 | 303615 | Pump to Block Gasket | 1 |

|

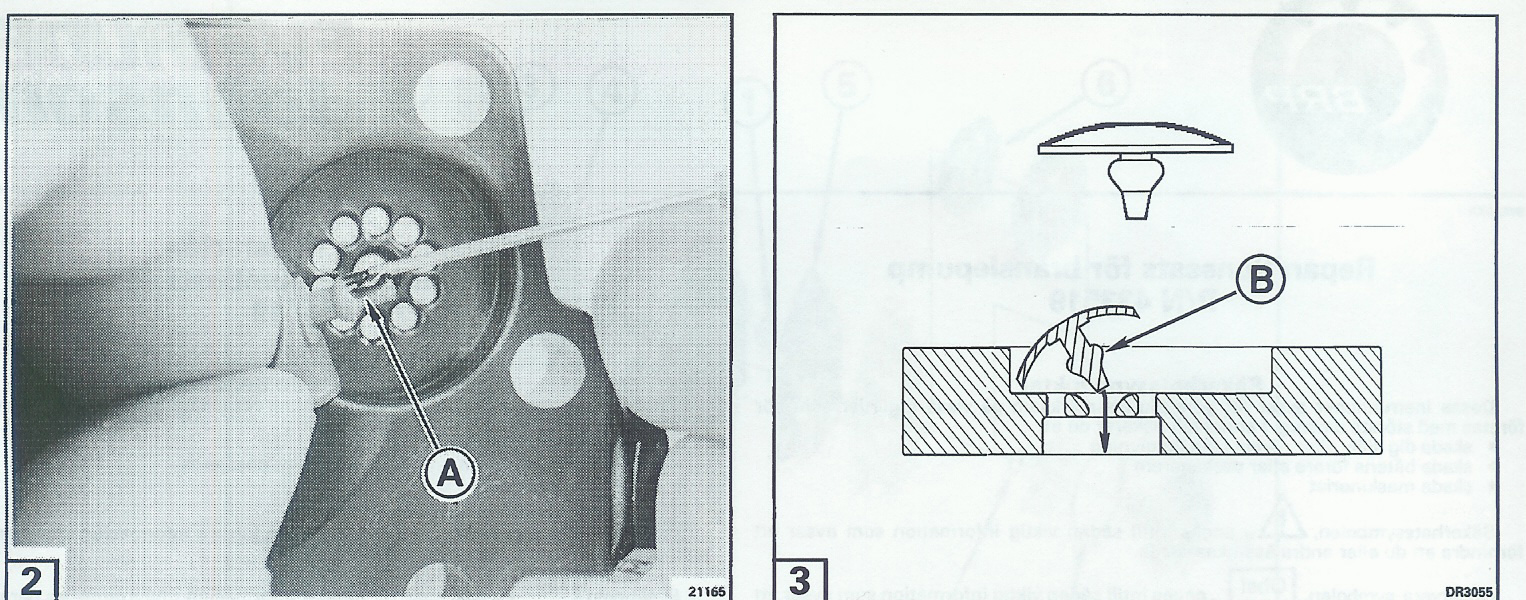

(2) Disassemble your pump carefully, taking note of the position and orientation of each part.

(3) Place a drop of oil on the stem (A) of each check valve. Install the check valves by pushing the stem thru the center hole with your finger tip or pencil eraser until the enlarged head (B) is thru the housing.

(NOTE) Do not use your finger nail, pencil point or ANY OTHER TOOL to install check valves or valve damage and premature failure will result. Do not assemble check valves into a dry housing, and do not pull valve stem thru the housing. Never reuse a check valve after it has been installed and removed. Removing a check valve damages it and reusing valve will result in premature pump failure.

Reassemble pump, hook up fuel tank and squeeze primer bulb to check for leaks. Fuel leaks could cause fire or explosion. Repair any leaks before operating motor.

You can see from the above information that this fuel pump is considerably

easier to repair than the older one was.

Back to the Main Ramblings Page

Originated 11-16-06 & last updated 01-19-2021 ***

Contact the author