|

|

Outfitting My 18' North River Aluminum Boat

|

Aluminum Boat ; I had owned a number of boats in my lifetime (80+ some years), from 8' prams to a 22' inboard work / fishing boat. The boat I had acquired in 1990 was a 20' fiberglass Tiderunner that was a great ocean boat, but life has a way of changing things unforeseen to us. My crew was my son and his nephews. The wife and I sold the business to our son in 2003, which as most business owners know, cuts down significantly on their leisure time. And the daughter then moved to Montana, taking our older grandsons with her.

This left me with manning this boat alone, or finding a whole new fishing crew, (however, I had a few bad previous experiences with fishing partners, so was somewhat skeptical), and the wife at that time had back issues whereby with even any slightly rough ocean waters was hard on her. And this boat was large enough to not really be one that a solo person could easily launch/recover without holding up the ramp time. I knew a lot of people, but did not have a lot of close friends because of being a busy business owner, and at my age most either owned their own boats, were not fishers, or were not alive anymore.

I also had a 16' riveted aluminum Hewes Craft sled

at one time and was happy with the

convertible top and open bow style as it allowed me to launch and recover at a

ramp that did not have a dock. So that was what I was looking for, but with a prop

motor, considerably more ocean seaworthiness and something that I could handle and fish alone if

need be.

Trying to sell these two was not going well because of the economy at that

time. After looking for a couple of

years, while the Tiderunner just sat in the RV bay of my barn, I pretty well had decided what I

wanted, and was doing afterhours repairs on farm machinery, boats, quads, guns or

whatever I could find to add to my boat fund. I had sat in a new 18' Hewes

Craft boat at a sportsman show a year or two before, spending considerable time with the salesman

listening to his thoughts on motors that would meet my fishing needs. I

even stopped at the Hewes Craft manufacturing plant on a side trip of a hunting

trip for more information as to what they could do to suit my needs. Yes,

they could accommodate me, but OK,

go home and save some more money.

Then in mid summer 2009, I found an add on Craigslist for a 2005 18' North River Mariner that had a 2005 Evinrude 75hp E-Tec outboard motor, and located on the Oregon central coast, at a price that I could then afford from the cash I had saved. My neighbor accompanied me to look at it, we ran the motor on muffs, negotiated on price a bit, and I towed it home.

The previous owner was not a fisherman, but liked to fish (there is a difference), and had owned it for 3 1/2 years (buying it new) and was fishing a local bay/river mouth. This boat was not exactly what I was looking for, but would work, and I could afford it. It was a basic boat, minimal sonar, no radio, anchor or mooring lines, no rod holders, but it did have a good convertible top, and the trailer did not even have a spare tire. But this could provide a base from which to launch my new fishing machine.

As you read through this article, you will see the years of evolution it took me to progress to what this boat is now.

Safety Afloat ; Safety on the water is/should be always your prime concern. One of the first things to add to this new boat to me, was to add this placard, as I always insist that everyone aboard wear a PFD. This placard placed prominently in the cabin does not (usually) require any explanation.

| The placard here is self explanatory |

|

|

Start Modifying For My Needs ; If you happen to have a boat that has those "steps" at the transom that take up floor space, you might investigate what is under and behind them. Usually the reason as I understand it is that the USCG requires floatation in all boats under 20'. Under this step behind it under the splash well was foam flotation for the rear part of the boat. However the space where this foam was inserted on this particular boat was not utilized to it's full extent. The splash well is tapered to the rear for the water to run out. The foam under this splash well appeared to be cut with a chain-saw very undersized which left way more open space than could have been utilized. I guess that is what you get in a modern day production line.

The floor space for this boat was crowded at the rear where most of action would take place in landing/netting large fish. So removing this boarding "step" provided much needed extra floor space, at least to me. By careful measuring and fitting the large section of foam that was under the step it was inserted under the splash well. This foam was simply sawed to shape with an old fashioned carpenters hand saw.

Also there was about 2 1/2" of space left on one side, where an extra sheet foam was inserted into completely filling that compartment with the exception of a 1 1/2" channel on the bottom outside for water run-off into the bilge. Now the left over foam was again fitted and inserted into the space above under the gunwale and the rod tray and again extra foam added as seen in the RH photo. The side of the aluminum step was cut off and the front simply moved rearward. In the end, no floatation was actually lost and the much needed extra floor space was immensely improved.

You will also notice the Ball Babies for securing downrigger balls tucked out of the way and placed in the corners on the rod trays.

| Here is the original Starboard "step". | Shown the Port "step" is removed for more floor space. |

|

|

|

More Storage Space ; For most dedicated fisherpersons with small boats, the boat does not have enough storage space. In the photo below on the left all the space under the seat that is on this pedestal type mounting is really wasted. On the right is the same boat and seat but with a revised storage arrangement. The seat boxes are made from 1/8" aluminum and have a 2" stainless steel piano hinge on the front for the lid and are held in position by 2 snap on rubber straps that were designed to hold firearms into gun racks mounted on a Quads front of the handle bars.

There is just enough room under one of these seats to now store a Coleman Port-A-Potty, much to the delight of the ladies in the family.

|

Note the

wasted

space under this seat on a pedestal |

After

-- Here the

same boat & seat as on the left photo, but using a Lazy Susan type swivel setting on top of a 16" X 20" welded aluminum storage box with a hinged lid |

|

|

|

| Here the Port under seat storage, safety dry box, tools in dry box, spare engine parts, spare starter rope, First Aid kit, distress flag, Dee handle gaff & 2 drift socks | Here the Starboard under seat storage, 5 gallon Port-A-Potty bucket, sea anchor, mooring bungee, poncho, cooking pans, towels & TP in zip-lock bag, & other miscl. |

|

|

Catch-All Box / Chair ; Where do you put fishing gear, etc. during the day when the action is on and yet keep the lures/leaders etc. out of the way.

When fishing, most of the time, I like to sit in the rear, and use my kicker motor to troll, using this swivel chair as shown in the photo below. On this chair the legs needed to be lengthened 5" so that the seat would swivel over the transom's splash well when used as a seat for operating this motor.

This extra height provided enough room to have a galvanized sheet metal pan made that was then brazed onto and between the legs. Now an update for this one, since I am near salt water at times, the bottom of this pan seems to become rather rusty, no matter how many drain holes I drill in it. My recent addition as seen below is to cut out most of the bottom, leaving about 1" bottom lip, kind of like it is now angle iron. Inside this I have now added expanded stainless steel metal that has 3/8" openings. OK, the small stuff may fall through, but that is what the plastic tray is for. The plastic bucket is a 5 quart paint bucket that I keep fresh water and Lemon Joy in. The spray bottle is filled with a mild solution of Lemon Joy.

Also it would be nice to get the whole chair frame galvanized as I fish on or near saltwater, but that is for another day.

|

Here is my fishing skippers swivel seat chair and the catch-all shelf under it |

|

PFD at Ready ; If you have your boat inspected, you will find that the Coast Guard wants you to be able to ACCESS your life preservers within 30 seconds. This does not mean that you can have them stored under all your other gear under the bow and still in the protective plastic wrapping. Therefore having them attached to the seat backs, erases all doubt as to accessibility. In the photo below you will notice that a strap of 1" Nylon was made up using snaps and it is attached to the top rear of the boat seats, holding the PFD onto the rear of the seat.

| Here the PFDs are out of the way & readily accessible |

|

|

Navigation Aids ; Modern day navigation depends almost entirely on electronics. For the well equipped fishing boat this now normally will be a combo sonar and GPS unit. Here I originally installed a Lowrance Eagle 5, then a HDS-5, but upgraded later to a HDS-7.

Here, I

also have a secondary sonar, as a backup, and/or different frequency.

And later there is a Furuno radar on the tower which it is

mounted on.

Also a VHF marine radio should be mandatory if the boat is to be

used on anything but an inland lake, at least in my area. And here I have

registered it with

the DSC

for emergency SOS GPS one button signaling.

| Here the Furuno Radar & Furuno secondary sonar screen are seen | Here the helm Lowrance GPS/sonar & VHF radio |

|

|

Docking Lights For a Small Boat ; Have you ever came in later than you had expected? Sometimes it can be REAL BLACK out there. And a hand held spotlight might be OK for coon hunting, but it sure is worthless if it is black, midnight, raining and cold when you are trying to hold it by hand outside to get your location and yet keep the glare away from you or the skipper (Been there-Done that), and in the process, you took the wrong turn into a blind slough.

Or you have to launch before daylight because of a LOW MINUS tide at your normal launching hours where the ramp is short and or shallow with a drop-off at the end of the concrete. If you did not launch at 4AM, you would have had to wait until about 9AM and then miss the 6AM morning daylight bite (and the salmon derby was on). Then just off the launch area some do-do heads have placed their crab pots, (Yah, close to the launch for in their morning retrieval) so you need lights to prevent tangling the crab pot ropes in your prop just so you can get out into open water out in front of this launch.

Initially I mounted 2 rod holder bases on the bow. I have had 2 boats of which one had hand rails. On this one, the clamp on rod holders were attached to the rails. The other a jetsled, has a squared off bow, perfect for attaching the rod holder bases. Economical automotive driving lights from Wal-Mart were affixed to a donor rod holder spline unit off of a set of old rod holders and attached by a 3/8" bolt threaded into the plastic A set of electrical wires was run forward under the deck to a cheap rubber 4 prong trailer connector. This way these lights can ride in my storage location and can be utilized only when needed.

I got some funny looks at times because of these fishing rod holder bases being in unusual locations at the bow, but they are there for a reason and that is to get me home easier and safely.

On the boat pictured below on the left you will notice the Columbia River rocker anchor setting in a anchor nest designed for secure storage and yet readily available. The wide roller is a benefit when retrieving the anchor. These anchors have the chain attached to the BOTTOM of the anchor and the chain is affixed to the top of the anchor shaft only by a large tie tape. This is so in case your anchor becomes fouled in something on the bottom, you can motor upstream, breaking the tie tape and then pull the anchor backwards out of what it may have become fouled into.

These lights worked well, but had an issue of being so bright on the forward part of the deck directly in front of the lights that it gave off a bright reflection was hard to see over. Then when I installed a radar arch on the same boat, I moved these lights to a permanent position on the outer front of the arch as seen in the right hand photo below. Here they are far enough to the rear and the convertible top shields the light whereby eliminating any night blindness for the skipper at night.

| Rod holder bases used to mount removable docking lights |

Here the lights from the left photo were moved to the top front of the new radar arch |

|

|

|

Passenger Grab Bar ; If your boat is not equipped with a hand rail / grab bar on the passenger side, it might be a good idea to install one. As when running, if you encounter any waves or rough water, this gives the passenger something to hang onto. You as the skipper have the steering wheel to help your stability in rough water.

In the photo below you will also see in the side tray my well worn chart book, including all my GPS locations and other printed material, like battery electrical schematic, port mooring/docking charts for the areas frequented, etc. The black box for voltage to my downriggers is also shown.

|

Hand-Rail

installed on port side with

chart book, & notice the 12 volt cigarette lighter receptacle on the dash |

|

|

Bilge Pump Indicator Light ; I made this installation after finding the bilge pump had died and probably had not been turned off after running it. In my old age, even hearing aids do not solve all problems and if you can not hear it from the helm, and forget to turn it off, who knows how long it can run. Sure the owner's manual says you can run it dry, but for 3 or 4 hours? And then when you need it, you could get nothing. This may not stop the motor failure, but it sure can not hurt if it helps you remember to turn the switch off. OK, I went to Radio Shack and purchased a small red LED indicator light. This light is about the size of a lead pencil. The installation was made in the dash right above the bilge pump switch.

You can purchase these in either red, green or amber for $2.19 at that time. Installation is simply drilling a hole .272" diameter, inserting the light unit, tightening the nut on the bottom side then connecting the red wire to the outgoing switched terminal wire (usually black) on the switch and the black wire from the indicator to the grounding strip.

As shown in the photo below this LED light is really bright, now there is no doubt if the pump is on or not. Some of the boat manufacturers are now using a switch that has a built in light in it when turned on.

| Bilge pump indicator light on |

|

|

Work /Cleaning Station ; Here since this boat was only a 18' and after modifying the floor space as shown in a previous section, the idea of adding more usable area seemed like a good idea, so a 3/16" aluminum cover was made bent, welded that fit over the transom and forward over the splash well on the Port side. The idea was to provide a cover for a 6 gallon trolling motor fuel tank (at that time I had a 2 stroke Johnson kicker), create a cleaning station, work area, seat or a platform where with a davit/pot puller positioned just forward of this location, a shrimp or crab pot could be pulled and the swung to the rear allowing a location to place the pot when removing the contents.

Shown in the RH photo, the yellow under the seat is a sheet of 3/16" polypropylene (could not complain about the color as it was free, which has faded out over time) that is to be used for the cleaning station. First thought was to make the polypropylene removable, but then, why, so now it is screwed down? And a Outer Banks 24" seat pad can be placed that is designed to fit on top of a 48/54 quart ice cooler. It has Velcro strips for fasteners. This cushion seemed to be a good idea at the time of building the shelf, however as a fishing boat it was removed after the first trip, and now just sets in the garage gathering dust.

Here you will also note rod holder bases and other stuff including a fish bonker.

The LH photo below is taken from the stern and shows blood relief slots milled on the back lip before it was welded onto the base. The stern mooring line passes thru a hole on the edge to the underneath compartment that it shares with a 6 gallon fuel tank and the wash-down hose.

|

Shown

from the rear, is the lip all the way around the rear and sides with rubber protective molding on

top & blood slots in the back lip |

Shown from front, the cleaning / work station / cushion with the removable cushion in place |

|

|

|

Combination Seat & Ice Cooler/Fish Box

;

Space again being at a premium,

the use of a 58 quart Coleman Xtreme ice cooler and a Outer Banks 30"

seat pad

on top was the choice. To keep the cooler from sliding around in the

boat, I had

some 1/8" aluminum bent into 1 1/2"angle and I then cut wedges out in the

inner corners as to be

able to bend it to fit the bottom of the cooler. These corners were then Heliarc welded together.

This angle frame was then screwed to the floor where I wanted the cooler to stay. Now it is secure from moving around, along with being able to be removed for cleaning, or carrying any fish ashore.

I left enough room behind this cooler and the inside of the boat to to allow a floatation throw cushion (Coast Guard required) to be able to just slide in along with the landing net handle to fit behind the cushion when under way.

To secure the seat pad to the lid, I originally snapped the cushion to the lid using the provided straps on the ends of the cushion. This proved to be not so good of idea when invitees tried to lift the lid, they always just grabbed the cushion cover, tearing off the snaps.

So the next year's plan "B" was to take the unit to a upholstery shop and have him cut the cushion down to match the cooler lid better (about 2" off the length). He then sewed a double (folded over) skirt and I snapped the skirt all the way around onto the cooler lid, (using pop rivets) leaving access between the two center snaps for opening the lid at the same time, as seen in the photo below. This now secures the cushion to the cooler and kind of forces invitees to use the lid handle recess as re-designed by being able to see the hand location on the cooler is.

| Cushioned side seat with cooler underneath, setting in the formed aluminum angle frame to keep it from sliding around. |

|

|

Large Fish Box ; OK, so we had found that the above 58 quart cooler is too small. I found this out in 2011 when my son and I had 5 salmon to 16# in it. The only way to close the lid was to remove the ice to make room for the fish.

If you have a boat that has an open bow, there is a lot of wasted space here. But here is another idea common on this type of fishing boats on the west coast. A Coleman 100 quart cooler can possibly be mounted in the forward part of the open bow, and held in place with a trucker's bungee cord. It took a lot of looking and measuring, but the one I now have allows it to be mounted far enough forward and is low enough which allows me room to open my center windshield and able to access the cooler from the rear and yet be able to board the boat over the bow from shore.

And I still have room on the bow for my Columbia River rocker anchor, anchor line and puller ball, forward bumper and 3 bow lines, plus a 12# river anchor used for securing the boat to the shore when launching when alone, all this makes for being rather crowded, but quite functional.

This boat does not have a under the forward deck fish box (as found on some boats of this type) forgoing it for more storage under this deck, accessable through small double doors in the bulkhead under the center window step through, which in my now mind is better.

| 100 quart Coleman cooler in the open bow as a fish-box |

|

|

I still keep the 58 quart cooler as the basis for a padded seat, but it also now doubles as storage for my small bait cooler, or lunch box, even a place for rain gear storage if I take passengers along.

Fish Box Ice ;

So you have spent a lot on all

the other things it takes to catch a fish, but when you catch one, or

more, how much thought have you given to taking care of the fish and

preserving excellent table fare after it is bonked?

Depending on the size of your cooler, 1/2 or even 1 gallon

plastic milk jugs when filled with water, then freeze them works great.

However they take up way too

much room. You can also refill and freeze 16 oz. water bottles.

The good part of this, is that when they thaw, you have cold water to drink.

And in keeping the fish box cool sure improves the quality of

the fish. For a link to extensive tests on cooler temperatures,

CLICK HERE.

My main fish box is now the above mentioned 100 quart cooler mounted in the open bow as seen above, and I have standardized on 1/2 gallon plastic apple or cranberry juice jugs as re-freezable ice containers. These are a more convenient size and 4 of them keep it cool for 2 days before they melt to about 1/2 but even then the cooler is still cool. What I usually do now, is to rotate two of these ice jugs each day.

What I have done now, as seen in the photo below is by cannibalizing old plastic shopping cart plastic sides and bottoms have made a bottom grate from this plastic. This holds my fish up out of any water/slime. I also usually put my fish inside a wet burlap potato sack, which keeps the cooler very clean, and if the sack gets smelly, trade off with another, wash the grungy one off with soap and let dry.

| Old shopping cart grates in the cooler bottom |

|

|

After fishing, I don't even have to remove the cooler, but just pull the burlap sack, with fish inside, pull grates if need be, the drain plug and wash the cooler out if it gets dirty, let it drain out the boat's bow scuppers.

Bleeding Bucket ; If you happen to be a salmon fisherman who frequents the Columbia River or other locations where Seals or Sea Lions frequent, or even the ocean with blue sharks being present, the old and popular method of bleeding your fish over the side on a bleeder rope could lead to a decrease in your take home catch. Even a few minutes could be disastrous. Enter a bleeding bucket. Here, a Kitty Litter plastic bucket works great, OR that 5 gallon one you have under your seat for a "Port-A-Potty", also works.

| Here a Kitty Litter bucket is used as a "Bleeding Bucket" |

|

Garbage Container ; Again space always being short on a small boat, and what do you do with used lure packages, candy bar wrappers, etc. ? In the photo below you will notice what is left of a 5 quart Pennzoil motor oil jug that is Velcroed to the bulkhead under the glove box. It being out of the way, but close at hand is very convenient. In this case the Velcro strips were attached to the bulkhead and plastic jug using contact cement.

| View a early view of the Port side cockpit before the radar, showing the garbage container & fire extinguisher, along with the small doors to the storage under the foredeck |

|

|

Windshield Defroster ; There are permanently mounted heater/defrosters available, but if your boat is smaller and you do not have the room on your dash, consider going to a RV store, purchasing a 12 volt hair dryer. These sell for less than $20.00, and usually come with a fold up handle for space saving and they work just great. They plug into a standard cigarette lighter power source.

| Portable 12 volt windshield defroster |

|

|

Another Defroster Trick ; Here is a trick I recently learned to keep the inside of your windows from fogging up. Use some liquid soap on a paper towel and wipe the inside of the window, BUT do not push hard enough to remove all the moisture. The theory was that if there are many minute soap bubbles on the glass, they deter any fog from forming. A rather cheap method that works.

Dual Battery Installation ; Depending on your needs/usage a 2nd battery could be beneficial. If you venture out in the ocean, or even a large bay and use a older 10 hp or lower, electric start motor for trolling that does not have a high amperage alternator like the new motors do to recharge what it uses from the battery, you could be in for a learning experience. You may find yourself in a situation where initially that when you restart your main motor that you sonar dies, this would be an indication your battery is getting low and draining power from your operating sonar unit. If you need to rope-start your main motor, once they get over about 75 hp, your efforts may prove useless.

Depending on your boat, you may have to be rather inventive to find a location that you can add another battery close to the original one. On mine the logical location would have been under the splash well and opposite the existing one. However that side has the gas filler hose so close that a regular battery could not have been placed there. I had looked this over before placing the wash-down pump there anyway.

By relocating the fuel/water separator at the rear, 6" to the starboard, I was able to place a 1/8" aluminum sheet tray with ends bent 1 1/2" down on the front and up on the rear to form a platform over my fuel tank suction hose elbows with enough clearance so they did not rub. The rear end of this plate is bent so that it just fits the angle of the inside of the transom and is bolted to it. The front downward lip is covered with a vinyl edging to insulate it from the top of the fuel tank.

A section of this base in the rear had to be cut out to accommodate the now relocated fuel/water separator. A plastic battery box base holds the battery in place. This battery box is to fit a group size 27 battery. The original starboard side batter was a group 24. I could not find another group 27 battery tray, so had to extend the base to accommodate the longer 27 battery. And in doing this, I also discarded the original tie down straps and installed a 1 1/2" nylon web with QD buckles. There is still enough room to get to the drain plug on the right side and to the bilge pump on the left if need be. Rather tight fit, but doable. And still enough room to store two boat bumpers.

Here I labeled the batteries with instructions (and had them laminated) for normal operations. You will also notice on the upper inside of the opening there is a 3 position switch that is connected to a 2 Amp trickle charge battery charger. Here I can toggle the switch to maintain either battery when at home in the RV bay for long term battery maintenance.

On the starboard side of the battery box, is a aluminum 6" X 6" lip that the new battery disconnect/selector switch is located on. There are more than one battery wiring system when it comes to dual batteries. Here is a link to one that I have settled on. CLICK HERE Go to the bottom section for this information.

On my boat I have a main disconnect switch (the red thingy shown below), I have each battery labeled and

instructions as how to set the disconnect switch.

I would normally only use the main motor as a "Get There" motor and then the trolling motor the rest of the day, unless it is a run back to make another pass. I keep all my electronics on while fishing and in the past (using a different trolling motor with less charging capacity) when only having one battery, I have had it get low enough that when starting the main motor, the sonar would drop out because of low voltage. This dual system pretty well isolates the main motor and yet when in the ALL position serves as my now normal run position of my trolling motor Yamaha T8 which maintains charge on both batteries when trolling, (which I do a lot of).

The #2 battery powers the main motor (and the hydraulics full time) and is charged by the main motor. But the dash/ignition are activated by #1 battery, which means the main motor will not start without the switch being in the #1 position, OR the ALL position. My trolling motor is tied directly to the #1 battery and is independently operational at all times, therefore I have emergency power even if a main fuse is blown.

However with this setup and the battery selector at #2, there is no power to the ignition switch for the main motor, so in essence #2 position is useless.

The reason for not wanting to run both motors simultaneously is that since both are actually connected if in the ALL position, without a diode to stop any voltage feedback where there could be possible damage to the newer main motor's computer, BUT in all probability, you would never run both at the same time.

Later when replacing these batteries, both are now group 27 Marine Deep Cycle batteries.

| You will notice that there is not a lot of extra space left in this compartment now, however there is just enough room for two bumpers on the right side |

|

|

Battery Terminal Nuts ; Be sure to remove the wing nuts (if that is what is supplied) on the batteries and replace them with stainless steel hex nuts AND tighten them down snug with a wrench. This simple thing may save you a lot of hard to find electrical problems later because of a loose battery connection.

Wash-Down Pump ;

Once

you use one of these little jewels, you will not go back to the bucket on a

rope to wash down the deck. Getting the fish blood and scales off the

deck while it is still wet makes life a lot easier than waiting hours or

days, then TRYING to remove them.

There is one requirement however,

and that is there has to be some way to get the water you just sprayed onto

the deck to be removed.

Here, it just drains into the bilge and pumped

out, and/or the drain plug pulled upon parking the boat. This is not

ideal, but for this type of boat, that is what you get.

The installation shown below is on this aluminum boat that required wire-feed aluminum welding the aluminum suction pipe into the transom. In the left hand photo below, the suction line and in-line strainer are mostly covered by the fuel tank filler/vent hoses in front of them. You can see the suction line coming thru the hull, with a 1/2" brass ball shut-off valve (with the red handle). The 1/2" aluminum pipe goes into a street Ell which then goes into a in-line raw water strainer. Out of that there is a 3/4" vinyl hose that is clamped in place and into the diaphragm pump to isolate any vibration or chance of the pipe breaking off. Another 3/4" hose on the pump outlet, up behind the panel and into another street Ell that the garden hose fitting is attached to for the coil hose connection to the outer (front) of the panel.

Behind the clear vinyl pump outlet hose is a fuse block for the pump. The wiring goes thru the aluminum panel inside a plastic grommet to the rocker switch near the hose outlet. The switch has a red indicator light in the rocker that shows when the pump is turned on.

This pump unit was made to fit into the space where the 2nd battery would have been. You may notice that the metal at the juncture of the kick-panel and the hull side has been relieved to allow blood, scales and water to be washed rearward. Behind this hole it was made sure that the foam insulation was not blocking the water escape channel. On this installation, I lathe turned all the aluminum pipe and fittings, simply because I had the metal lathe, it was a challenge and I was not sure I could purchase any aluminum fittings, much less the proper length ones without making many 100 mile round trips to the nearest marine store. A later note - the upper close coupled aluminum Ell fitting deteriorated to where it fell apart after the first year, probably because with this pump being pressurized, that salt water stayed in this area even when shut off. I then made a replacement out of Nylon which solved the problem.

Here the coil hose is unscrewed from the panel fitting and stored until needed, with a protective cap attached onto the hose fitting when not being used. A regular rubber drain plug was ground down to fit the water inlet that was welded into the transom as a emergency plug in case of a failure to the pipe system inside.

I am amazed at the pressure and volume that this pump produces, it even has a built in high pressure cut out when no flow is being demanded.

And later I installed a 2nd battery in the center over the rear of the fuel tank. Believe it or not, but there is still enough room in this area for 2 rubber boat fenders.

| Shurflow

wash-down pump installation in a pre-existing boat location behind a

fold-down door & nestled in with the fuel tank fill / vent lines. |

The coil

hose, nozzle & rocker switch mounted on the front panel, the switch itself is protected by the rod-holder when the hose is off. |

|

|

|

Smelly Bilge ; There is a downside situation in using this type of wash-down unit where you wash the deck down and into the bilge where your bilge pump then pumps it over the side. But in use, if you are a fisherman, you will get blood and fish scales washed into the bilge of most boats that are not equipped with self bailing scuppers.

Then after a while, you may well have an unpleasant smell

coming from your bilge/battery access area.

After using the boat

for a week-end and then parked it in the garage during a hot summer, have you climbed aboard only to

smell a not so peasant aroma of decaying blood? You may want to

wash the deck down with some soapy water, raise the tongue jack high enough

to facilitate draining, pull the drain plug and open up your

hatch to the bilge to let things air out. You may even need

to put some bilge cleaner in there, or at least a small amount of detergent

soap and or Lysol to help this clean up process.

Also your one of your winter jobs may be pull part of your deck and scrub the inner hull down, if possible. This is also more of a necessity if your boat is made of aluminum and you on occasion use it in salt water. Salt corrosion that is in hidden places make for unexpected and expensive repairs.

Bilge Ventilation ; While we are at the bilge, may boats also have an access door to the batteries under the motor well and into the bilge. If your boat is a aluminum, it may draw moisture or have a lot of condensation in this area during winter storage. It may be beneficial to install one or two louvered vents, otherwise you may need to open this cover (which may be a invitation for small critters) to let things dry out better.

You might consider placing a couple of 6" plastic ventilation louvers in the battery door, (as seen below) or where-ever the door goes into the bilge area.

| Two louvers installed in the battery/bilge cover door, & a measuring stick below |

|

|

Control Using a Kicker Trolling Motor ; There are a few methods of usage here. Since most large "Get There" outboard or inboard motors do not troll down slow enough, you may see usage of the Happy Troller plate, or actual drift socks, even drags made of 5 gallon buckets to slow the boats down to a trolling speed.

Others oblivious to fishing/trolling requirements just troll fast with the main motor hoping to chase down a fish.

(1) One suggestion is that many times wind and or tidal movement contributes to a steerage problem, that if you are using a smaller trolling motor, it may at times be hard to control the boat UNLESS you lift the large motor's/outdrive up out of the water. If you leave it down, the larger motor's skeg cuts into a lot of the steering that the smaller motor is now struggling to overcome. Jet motors are less susceptible to this as there is less hanging down.

On larger boats or those with even canvas tops, your smaller trolling motor does not have enough power to overcome the big rudder that you still have in the water right next to this smaller prop that you are trying to do the steering with especially since the trolling motor is running slow and IF the wind is pushing the boat beyond your slow moving control. This can be very counterproductive at times, hence by raising the main motor this increases your steerage ability when using the smaller motor for power. Just remember to lower the main motor when you start up to make another run, if not, the motor will sound loud and could possibly ruin a water pump impeller if not in the water ASAP or before.

| Here the

main 200hp motor is lilted UP with it's lower unit as much out of the water as possible and where all steerage is done manually by the smaller 8 hp trolling motor |

|

|

Those of you who are running a TR-1 autopilot unit on the trolling motor may also find the above method beneficial.

Depending on the location, proximity of other boaters and the weather, I usually like to sit at the rear on a swivel chair, run the trolling motor, thereby looking forward, watching the rods and being able to see where I am going all at the same time. And some fishing areas we may not have the luxury of trolling in wide open spaces, but you are pushed (by other boaters or water depth, even floating weeds) into confined areas like a river channel in a bay or a hot spot at a special water depth.

Don't get me wrong as I also like the comfort of a cabin as much as the rest of you, but I have a problem of being able to pay attention to the rods at the rear (the reason I am there) while still watching forward trying to stay out of the way of those idiots who are running a TR-1 auto-pilot and do not watch where they are going because of it (or think they are more important than your smaller boat). Also many times since I am retired, when the fish are there, I fish even if I have to be there alone.

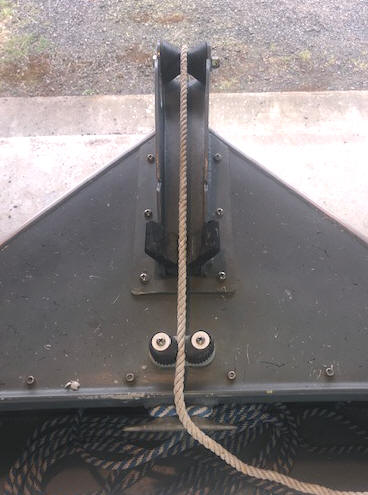

(2) The other more common/preferred method is to connect the trolling motor to the main motor by means of a quick disconnect coupler, leave the main motor's lower unit in the water to act as a rudder but without this main motor running and steer both from the helm steering wheel, as shown in the photo on the below. It is however not ideal if dealing with a fleet of "Bumper Boats" at buoy 10 on the Columbia River where your rapid maneuverability is limited. This method is used especially if the weather is nasty and you can sit inside under the convertible top (even with a propane heater going) if so equipped.

| Here a

stainless steel quick disconnect tie bar connects both the motors

with main motor down & steered by steering wheel if in inclement weather |

|

|

(3) Another helpful thing to do if you happen to have a boat with a center windshield that folds out of the way for bow access, is to open this window, allowing the wind to flow thru the boat. This helps somewhat by helping to eliminate the sail effect of the convertible or hard top. This can be used in addition to the above trolling situations where you may be encountering some wind problems occurring in trolling where there is wind involved (and on the water isn't that about always)?

Mounting Your Downrigger ;

It is a very proven method of effectively fishing by using downriggers.

Mounting them in proper locations on your boat needs to be thoroughly thought out

before you start drilling holes. Depending on the number you are intending

to run AND the size of the boat will also be a factor, but lets say just 2 in my

case. Number one priority is that they need to be easily accessible and in a location where

the wire (when making a turn) does not get tangled with a prop, (especially the

trolling motor's) OR rubbing the sides of the boat in a close turn. This

criteria with boats from 16' to 20, usually places your bases at the rear, but forward

usually about four feet, as when trolling the gear will be behind the downrigger

boom. And you need to EASILY access all of this gear.

Some boats, especially aluminum may have low pipe railings that limit the

locations, other aluminum ones may come with welded on metal bracket bases

so you have little choice here, but their placement is normally well planed.

I am not going to get into a discussion here as to which

brand of downrigger is better, but I have used/owned numerous brands and have

settled on the Scotty Electric. However I do not like the Scotty swivel

base, (for my boat it is too tall) but the Cannon which has a considerably lower profile

is my choice, so I have made a 1/2" aluminum adapter plate to

accommodate the Scotty base on top of the Cannon swivel base (as seen in the photo

below).

For me, I want extendable booms, with the one on the trolling motor side being longer, (to clear it's prop).

Swivel bases have numerous advantages, (1) The unit can be swiveled from a out of the way position while in storage or running to the fishing grounds, to an operational 90 degree out position for fishing in seconds. (2) The closer they are to the boat when initially deploying, helps immensely if it is rotated in when attaching the downrigger ball and getting it in the water, then rotate the unit to outward fishing location. If you try to attach the ball on the wire and the rigger all the way out, when you let go of it, with that heavy ball and of you let it drop even any slight amount, it will drop enough to break off the wire or ball connection, loosing the ball and possibly some wire. I HAVE SEEN THAT HAPPEN NUMEROUS TIMES. (3) The longer the units are (farther out they extend), the harder it is to safely retrieve your clip to reattach your line to so you need a happy medium OR, Scotty makes a retrieval system that helps in the above two instances and is worth investigating. However part of this type of fishing is to help spread your gear out so you need to compromise on the boom length. (4) When netting a large fish, it may be beneficial to pull all the gear on that side, and swivel the downrigger forward and out of the way, OR tip it up, eliminating chances of fouling your gear, or the fish.

| Here is my modified low profile downrigger swivel base |

|

My downriggers are the old Scotty dual belt style which required only a size #14 wire and a 20 Amp fuse. Finally I splurged and bought myself Ace Line hauler electric shrimp/crab pot puller for Christmas, which mounts on the Scotty downrigger base AND plugs into the Scotty electrical receptacle. However this pot puller has a considerably more heavy duty motor, requiring heavier wire and a 40 Amp fuse. My old fuse block was made for the old style glass tube type fuses and trying to find a 40 Amp glass fuse is about impossible now. Which meant that I had to change fuse blocks. What I came up with was from a auto shop that specializes in radios, including the boom boxes. Here I purchased a dual spade type Maxi Fuse style, dual plug in fuse block.

So then remount the new block, and pull all new (larger #10) wire. This in itself was a real chore, even after pulling the rear inspection covers, one battery and for an 85 year old geezer laying on my side, reaching back without being able to really see well in order to attach the new ground wires to the ground bar under the motor splash well, and behind the fuel filter proved almost impossible. The seized screws holding on one of the inspection covers were impossible to remove, so I by using a angle head grinder, and ground off the heads. I finally got the 2 top broken screws out, (using a lot of penetrating oil, pounding, and heat, then using a Vise-Grip pliers) but not the bottom ones, which I just ground down flush and re-drilled/tapped new holes 1/2" above. And then repainted the cover.

| Here is my fuse block for both downriggers, mounted up under the rear starboard gunnel |

|

Drain Holes For an Open Bow ; Many original open bow drain holes that you may find on these river boats are smaller than I like to see. On the photo at the left below shows what it looks like originally and on the right my modification after enlarging them and by adding a clamshell cover.

In looking for a clamshell, most marine stores do not inventory these larger ones and not really knowing the size needed is not to my liking to special order something that I am not sure I want (especially at $32 a pop). I knew a fellow who had purchased a Hewes Craft boat and it had the size I really wanted. I called Hewes Craft and for less than $20 they shipped me 2 stainless steel ones.

Then a few years later, one got knocked off, so another call to Hewes Craft, but guess what? They discontinued using them because of possible liability, IF it got plugged and could not drain efficiently.

| A view of the original scupper drain hole | Clamshell covering the larger scupper hole |

|

|

|

Need Internal Lights? ; How many times in dim light or even if your boat is on the trailer that you go aboard and need better lights to find something? Some of the needed locations would be prohibitive to run wiring to, so enter the small stick-on battery operated lights, of which io have one under the bow storage. However it is my experience that the adhesive can deteriorates over time and the light falls off.

In the LH photo below a 12 volt LED compact light is wired into the aluminum side rail behind the captain's seat. The toggle switch is under the rail and just ahead of the light. This thing is small but bright enough to be valuable when rigging/tying gear up early in the morning before hitting the water.

In the RH photo below small automotive amber fog lights are mounted on the rear of the radar arch, and pointed so the whole rear deck is illuminated. These two lights have a single toggle switch placed under the Port gunnel so as to not being readily flipped on accidently. These really help if you want to be on the water at daylight, and need to get your boat ready before the sun comes up. And being amber, they do not blind nearby boaters if tied to the dock.

| Here is a small mid LED light installed in the starboard side rail | Here we have rear deck lights mounted on the radar arch's outer corners |

|

|

|

Freon Signal Horns ; These devises are way better than most electric horns commonly found on recreational boats. As long as the canister is intact and filled with Freon, these horns are very effective, producing a signaling noise that can usually be heard even above the sound of operating a boat. They are relatively cheap and can be refilled by purchasing a new canister.

However not all of these horns/canisters are the same and canisters of different brands may not interchange. Even ones of the same manufacturer may be different IF the model is not the same. These canisters screw onto the horn body, however the threads are not universal. Most of these threads are about 7/16" in diameter, some are fine threads while others are course threads. Then of the smaller PWC style, there is one style that uses a longer course threaded plastic tip. However this horn has the push button on the rear, not on top.

The three that I have are Falcon brands, the small one is designed for Personal Watercraft, while the others are more for conventional watercraft. Both are Falcon brand and use the fine threaded canisters. One brand was encountered that uses the same fine threads as the Falcon, and that is SeaChoice. The other small Falcon brand unit that I have has a belt clip and is called a personal protection model, (this may be good for ladies in a urban area or hunters in bear country) however it has the course threads.

West Marine also sells an almost identical larger horn, the

only apparent difference is that it is red, however it uses the course threads.

Somewhere I saw an add for refillable canisters using compressed air.

But I do not know which threads these use.

In my search for a compatible threaded canister, I even contemplated soldering or Epoxying a tire valve stem into the canister and making my own refillable compressed air unit.

| Here Freon a signal horn, this one is a Falcon brand |

|

Power Flare ; If you ever get in a situation where you need to have your boat located on the water (especially in the dark), sure VHF may notify the Coast Guard, but what if it is dark and you are so busy (or you may not have programmed your GPS/sonar unit to show the coordinates on the sonar screen) that you can not give an exact (GPS) location directions? Sometimes you may need all the resources available to be identified/located.

I saw this happen close-hand in 2015 on the lower Columbia River during the Buoy 10 fishery before daylight one morning. A small recreational fishing boat radioed the Coast Guard that they were dead in the water AND taking on water.

Communication was sporadic from the boat in distress, as he was apparently very busy. He finally answered that he had drained the fuel filter and had the motor running, AND was trying to get into the Chinook channel. We were still tied to our berth in the Chinook boat basin waiting for daylight (being a newbie there) before I attempted to join the crowd and head out that narrow channel in predawn hours.

The large ribbed Coast Guard boat came flying into the entrance of the basin looking for the boat in distress. He was not here, which meant they had missed him somewhere on their way in, as apparently they had came from downriver and he was coming in from upriver. More radio communication and this time the distressed boat gave a more recognizable location. The Coast Guard boat had then turned and was headed back out the Chinook channel, and they then soon had visual contact as it started to break daylight.

Then as daybreak came, as we exited the basin, the distressed boat, (about an 18' or 20' aluminum convertible topped I/O) with 3 passengers, under it's own power, but being escorted in by the Coast Guard boat. It did not have a lot of freeboard at that time. My best guess is that they had forgotten the drain plug when launching in the dark that morning, and in the predawn the first clue that they were in trouble was that a fisherman's feet got wet when they began rigged up.

From our vantage point still tied to our dock, it became obvious that I may need to expand my resources of emergency boat safety devices. My nephew then introduced me to PowerFlare http://www.powerflare.com/ . This is an ingenious identification device. For the price of about $55 plus shipping, it has many uses, being designed basically for emergency responders, and for being used in a situation described above, automobile emergency, being in a hunting pack, or left on your dash for you to relocate your vehicle on a night clam dig. These can be had in various colors of light, are waterproof and uses a Lithium battery. It has an outer case made of 16 Nylon/rubber protective rings.

Then just a few months later, I found a knock-off of the above, but less light modes (5), non waterproof and uses 3 AAA Alkaline batteries, for $14.99 ( 2022 prices $24.95). This one comes with a hook and magnet on the back. It looks similar but only has 12 protective rings. This one is simply called a LED Safety Flare and sold at some automotive hardware stores and distributed by www.wilmarcorp.com . Brightness on both is comparable however. But just be sure to check the batteries on these before each season.

| PowerFlare in one of the ten flashing patterns available |

|

The Motors ; This boat came with a 2005 75 hp Evinrude E-Tec, which is a fuel injected 2 cycle outboard. It was the 2nd year of production of this new type outboard made by Bombardier. The is pretty well a match as far as motor to boat. This boat has a 12 degree bottom, (designed more as a bay/river boat and compatible to use either a prop or jet motor). With a full tank (35 gallons) of fuel, 2 persons onboard and all our gear, on a smooth water with slight ripples I can get 32 MPH. That is plenty fast as on the water speed can get you in trouble.

The one drawback on this motor is that it is so computerized that you can not even adjust the idle without doing it on computer. Therefore it can only be worked on by authorized mechanics who have had factory training and access to the factory computer programs. However, even though it has had a few problems in the 17 years that I have owned it, I am happy with it.

Then on May 27, 2020, BRP (Bombardier) announced that they would be retiring the Evinrude brand and would exit the outboard boat motor market, in favor of manufacturing recreational boats. This Canadian company stunned the recreational boating industry with their announcement above. “Our outboard engines business has been greatly impacted by COVID-19, obliging us to discontinue production of our outboard motors immediately. Warranty and spare parts will still be available to cover their obligations. Which probably means essential parts will still be available, but in the long haul, non essential parts will dry up. Also it is suspected that one of the aftermarket suppliers may pick up essential parts like water pumps, fuel injectors, and piston rings.

For trolling, which I normally do, I have outfitted it with a 2008 Yamaha T8 (high thrust 8hp) 4 stroke outboard.

Preventing Boat Trailer Theft ; It can be rather disheartening to return to the launch after a day of fun / fishing only to find your boat trailer missing from your towing vehicle. Many of us do padlock the trailer hitch lever down so it can not be disconnected from the ball. And this can also be a good thing to get used to doing as it is a reminder to not forget to snap the lever down onto the ball (Been There-Done That), which can get embarrassing at reloading time.

But what about securing the hitch extension into the bumper's receiver? If you just use the original spring snap clip to hold the pin in place, it is rather easy to pull the pin, slide the trailer rearward enough to get the extension out of the receiver and then transfer the extension to a waiting vehicle that has the same commonly used receiver.

To prevent this, I have drilled my extension pin out enough to also accept a padlock bail, as shown in the photo below on the right.

It is nice to purchase 2 or 3 padlocks using the same key for this situation. You do need to remove the extension padlock occasionally and clean the padlock up so it will function when needed. I have found that if you don't, the lock may become hard to unlock. Therefore it may be prudent to smear some Vaseline around where the bail enters the base to keep out water (which turns metal into rust) and put Duct tape over the whole bottom and key slot to keep the dust from getting inside the tumbler.

For those of you who may wonder what the upper license plate frame says, it is "Crime Control" on top, and the bottom as seen, "Not Gun Control".

During the hot dry summers we seem to be having regularly, if you are towing a boat or trailer, make sure the tow safety chains don`t drag on the pavement (and criss-crossed properly as seen in the photo on the left below) which could produce sparks if too long and drag, which then can start a fire.

| Padlock on the hitch | Padlock securing the extension to the receiver |

|

|

|

Trailer Spare Tire Theft ; Don't overlook padlocking your spare tire to the trailer as shown below. Here a short section of 1/4" X 1 1/4" flat steel was welded onto one of the securing nuts, a larger hole drilled so the bolt would have clearance and another hole matching the next wheel lug bolt hole that is then secured with a padlock. On this unit, the padlock hole end needed to be bent down to minimize the distance allowing to be able to snap a standard shank length padlock lock into. Also the upper part of the hole above the lug nut that was welded on the underside, a welded on hollow cap was (with grease inside) on top of the strap to eliminate a rusted bolt at removal time.

You will also notice that this wheel is turned upside down as to protect the valve stem from being accidently stepped on and broken off.

And remember to check the air in this spare frequently, along with applying grease on the padlock, so as to being able to unlock it when the time comes.

| Padlocked spare trailer wheel |

|

Some boaters have even had their tires/wheels stolen right off the trailer at launch parking lots, so after the fact and to secure them next time, they run a heavy chain thru the wheel spokes and around the axle and secured with a padlock. If they were using a more secure launch, this chain can serve double duty by being the same as you could use as extra weight for your anchor.

Trailer Step ; I was once told that necessity was the mother of invention. Actually in my case PAIN was the mother of invention. On one of my previous boats, (a 20' Tiderunner) I forgot to lower the radio antennas after the boat was out of the water and on the trailer, so climbing onto the trailer fender and then hopefully up into the boat, my foot slipped on the wet fender and my leg went into the narrow space under the chine but above the trailer fender. It barked LOTS of skin very badly off my shin enough that there had to be a better way to board this boat while on the trailer. Hence any boat I own now has a boarding step on the trailer.

In the photo below, this step was fabricated using just a 2" X 2" angle iron was arc welded onto the side guide with brace straps also welded supporting the under outside edge. On top of this was a section of galvanized expanded metal cat-walk. This was then spray painted with a cold galvanizing paint for rust prevention on the brackets. Just be sure that you keep the inner edge far enough away so the hull does not get gouged when loading.

| Expanded metal step welded onto rear of the side of loading guide |

|

|

Boat Coast Guard ID# on Trailer Tongue ; OK, now here is a thought. What if you did not return to the launch when you were supposed to? You left a somewhat float plan, or the family knew where you were going, but not your boat number, where law enforcement/SAR then had little to go on. But they should be able to find your towing vehicle and trailer. Here I used small self adhesive decal letters/numbers relating to my boat numbers and placed them prominently on my trailer tongue.

I hope this will never come to where it is needed, BUT it surely will not hurt being proactive.

| Here my Coast Guard boat numbers are placed on the tongue of my trailer. |

|

Out of Sight, Out of Mind ; This old adage can come out and bite you IF you have an aluminum boat, but even occasionally use it in or near salt water. Here I am referring to a boat trailer that was supplied with carpeted bunks. If you submerge these bunks in salt water, (which will soak up AND retain the salt) and you then let the boat sit on the trailer for extended periods of time, (like during the winter months) this salt can start to corrode the bottom of your boat. I found this when I was waxing the bottom. My trailer was an EZ Loader, so I went to my dealer and ordered these factory 18" Nylon bunk channel glide covers which just overlay the carpet and are screwed onto the bunk from the sides.

These are not cheap, (like $15 each and you need 6) but they are very worthwhile and accomplish two things. (1) It makes the boat easier to slide off the trailer AND winch back on if in an area where the trailer can not be backed down far enough to ease the offload/reload process. (2) it gives the aluminum hull a better place to rest without getting subject to the salt trapped in the carpet bunk AND the corrosion associated with this situation.

|

Here

Nylon overlays were added on top of the old bunk carpet.

Note the step above the LH finder. |

|

|

Wheel Bearings/Seals ; Well, after this boat sitting for 5 years because of my wife's medical condition, and I finally got it back operational, and in replacing one of the tires, I bumped the outer clear plastic seal cover/cap of the Reliable oil bath bearing cover, cracking it enough to cause a oil leak. And not repairable because of them being 16 years old and the plastic had became brittle. But my online research came up with a new improved style aluminum threaded cap with a clear plastic window insert, eliminating this issue.

OK, while replacing this outer cap, why not check the bearings and replace the rear seal and the lubricating oil all at the same time? As the last time I changed the oil was 9 years ago. After taking them apart this time, the bearings however were as good as new.

New caps are $20 and the seal $4.50 each, and available from the trailer manufacturer E Z Loader.

| Here the old plastic cover that is threaded directly into the spindle | And here the new aluminum cover with it's clear inner plastic sight glass |

|

|

| Here you can see the old broken plastic cap on the left, & the new aluminum (outer & inner views) on the right with the O-Ring seal |

|

Trailer Hitch Pin Clip ; OK, on your trailer pre-check, you have checked all the usual things like lights, tire inflation, hitch latched down, safety chains etc. There is one more check that for those of us who keep the hitch extension with the ball on the vehicle all the time. Double check the receiver to extension cross pin's retainer snap clip.

I recently had an eye opener. Since my wife has been ill and was am her 24 hour caregiver, my fishing time has dwindled to ZERO unless I can find someone to stay with her. And with the hitch extension in my pickup IN the garage, I hate it when I forget, and walk behind the pickup so close that my shins get banged on the extension. So I took it off. I normally retain the cross pin with a padlock. However in my sprucing up her lawn, I needed to use my small utility trailer to haul a few loads of Beauty Bark. OK, now where did I put the cross-pin and padlock, so I just used a different but regular standard one which used a spring clip as a retainer.

On my fourth and last load, I got a clunk sound and slight jolt when I started out. I did not really think about it until almost home and slowed for a corner. There it was again. Well I only had 2 miles to go, so I will look at it then. When I drove into my driveway and onto the lawn, I had stopped short of getting the trailer off my turn-around, so I pull ahead a few feet. CLUNK again, but this time with a JOLT.

The pin had came completely out and apparently in the process, the pin may have been only in one side, allowing this slop and noise. And when the pin fell out, the only thing holding the extension in the receiver was the tongue weight for that short distance. But here and partly on the lawn, when I accelerated more, pulling the whole extension out of the receiver and hanging in the safety chains when it pulled completely out.

My MORAL OF THE STORY here, is double check that snap retainer OFTEN and especially if you hear a non-normal noise of feel a clunk. And even carry a few extras snap clips. Or use my padlock system.

Moving a Trailered Boat for Storage ; The usage of a trailer dolly can be a blessing for many boat owners. It may not work well for boats over 3000# or if it stored on gravel unless you happen to be a gorilla. But if you have a concrete garage or storage area, this sure beats trying to roll it on just the trailer jack wheel. You can find them in many places, I got this one at Harbor Freight for about $70. However for the height of my hitch/trailer tongue, I had to make a new ball 3" taller to raise the ball to match my pickup hitch.

It also helps in getting the trailer close and lined up for the towing vehicle when attaching the trailer to the ball.

| Trailer dolly in use |

|

|

Water Spraying on/into Motor at High Speed ; OK, this one is going to take some explaining. Essentially the transducer and water temp/speedometer senders were creating a situation where they spraying water on the motor, enough to short out a ignition coil.

One day of fishing saltwater off Washington's Westport created no problems, the best safe speed was 13 MPH because the water was choppy enough that. And the next day was the same until we headed back to the boat basin, Now we had the milder waves and the wind was on the stern and the water was calmer. A speed of 20 MPH was then achieved. However after about 1/2 hour the 75 hp Evinrude E-Tec (fuel injected 2 stroke) motor lost power on one of it's 3 cylinders. It would sputter back onto the 3rd cylinder occasionally, then finally go back to running OK for 10 minutes or so, only to revert again back to missing for 20 minutes or so. The reduced speed was 9 MPH. We had about 10 total miles total to go including cross the bar before we could get to the boat basin. A cell phone call was made to the boat mechanic for reassurance that we could make it that far without creating damage to the motor.

As it happened, we regained full power while crossing the bar and then again as we approached the boat basin. It was then when nearing the boat basin that my fishing partner noticed all the water spraying onto the side of the motor. It was coming off the area at the transducers. At the dock I took the cowling off and there was water dripping off some of the motor components.

Now came the detective work. This GPS/Sonar unit had came off my previous boat and was known to not cause that same problem. There had been some slight problem initially on this newer boat, but they had been adjusted so there was no excessive spray on the lake trials. What we have here, it is on most aluminum boats the bottom metal extends about 1 1/2" beyond the transom. There is a 1 1/2" X 10" aluminum channel welded onto the bottom of the transom for mounting this type of transducer hardware. HOWEVER there is a 1/4" gap between the bottom of this channel and the upper edge of the extended bottom aluminum. It appears that when we were running out that day it was choppy, we did not go fast enough as compared to running with the waves and WIND pushing us the second day. I suspect when we ran at the faster speed, this hollow channel against the transom and the narrow gap below created a venturi then sucked air down the transom, inside the channel and against the water traveling just under the bottom. It was then diverted up against the back of the transom by the wind. This wind on our stern then blew this FINE spray against the side of the motor which was then sucked into the motor breather location on the upper rear of the cowling.

When this fine spray was sucked into the cowling cavity

and

onto the rear of the motor where the ignition coils are located, the moisture shorted

out the bottom coil where the inner cowl air ducting terminated. When we

were forced to run at the slower speed when it was missing, the warm motor dried the water,

and we were off and running OK again at the higher speed until more misty water

was sucked/blown in.

You will notice in the photo below, two transducers, this is

because my main Lowrance sonar/GPS is supplemented by a separate Furuno

sonar.

Apparently the boat factory felt that this gap at the bottom was to not allow any place to trap water when the boat was hauled out. I had repeatedly tried before to adjust the transducers, but could never get a 100 % non-spray as compared to when they were on the previous boat. I have finally given up trying to solve the problem and concentrated on just patching the situation so it does not effect the motor. I thought about trying to plug this gap with foam, but these transducers are attached with bolts and the nuts are in this cavity. So my remedy was to make a 1/8" aluminum hood extended rearward about 3" to go over the transducers, diverting the water back down and off the motor. This 3" did not do the job totally so another was made (shown below) that extended 6".

This is a 2005 boat, a friend bought the same boat but a 2009 but the factory had made changes in that mounting bracket, placing the transducers closer to the transom. Maybe I was not the only one with a problem. My thoughts are that this gap between the hull and the bracket acted as a venturi when full speed was achieved, sucking water up from the rear edge of the bottom and then blowing it rearward. And with a trailing wind, the water was blown into the motor's air intake at the top rear of its' cowling.

|

A metal deflector over the transducers diverting water spray. The welded hole just barely visible immediately to the right of the hood is the wash-down pump inlet mentioned above. |

|

|

Prop Guard ; Have you ever tangled fishing line around your kicker motor's prop? Or worse yet downrigger wire? Which would cut dramatically into your fishing time, and possibly loosing expensive lead downrigger balls because of this tangle?

Sometimes even though you try hard to have this not happen, things just go wrong. Maybe you are trolling and happen to go thru a rip tide with the current pushing you one way while the wind is pushing you another way with 2 downrigger wires not where they should be as the bottom came up on you faster than expected.

Here comes the use for a propeller guard, maybe not a cure all, but can not hurt having it in place. These are usually made of 1/8" stainless steel about 2 1/2" wide and bent into a circle with about 1" of clearance around the outer edges of the prop. They are bolted onto the top of the cavitation plate of the motor with 1/4" stainless bolts. There is a welded tab on the very bottom that is bolted to the bottom of the skeg for stiffening front to rear. These may seem to be expensive at the retail price of over $150, but what if you loose a couple of 12# downrigger balls that retail for $40 each. This device may also save the day by keeping your spider wire line from getting into the prop shaft seal and cutting it to shreds and you have just started fishing on the first day of your vacation.

Somewhere it was said that these also improve the thrust because it does not allow the water to be pushed off the ends of the blades. Also the steerage is improved at low speeds because it kind of makes it's own contained thrust channel.

The one shown below is a Home Do It Yourself Endeavour copy of a aftermarket factory version fitted to a Yamaha T8. Thank you Cabelas for having an open box so I could get measurements.

| Consequences of a unguarded prop | Prop guard installed on trolling motor |

|

|

|

Corrosion Under the Cowling On the Powerhead ; As a addition to the above situation, it is recommended that after a day on saltwater as you will get salt air moisture inside the cowling that will dry on the warm motor to remove the cowling, wash the motor down with Salt Away, let it set a while and then wash with fresh water. How many used motors have you seen that have been used on salt water that once the cowling is removed, there is a massive amount of peeled paint and rusted bolts which surely devalues the motor when you want to sell it.

If and when you need a mechanic's services, this is embarrassing for one and very possibly expensive to you also. One way to also help prevent this situation is to be sure the outside of the powerhead is clean, and then coat it with a protective spray in the form of Boe Shield. This is a product developed by Boeing Aircraft Co. to be applied to parts of airplanes to eliminate corrosion. It dries to a thin clear non-sticky protective film.

It is still recommended that even after the above treatment that you still wash the powerhead down with freshwater after saltwater usage.

Open Bow Cover ; One of my previous small boats was a 16' Hewescraft jet sled. I made a vinyl bow cover with the snaps close together and put 2 inflated kids swimming pool rings under it to support the vinyl from underneath to keep any water from coming over the open bow if the weather gets nasty and filling the front compartment. One of these is pretty well inflated and the other only as much as needed to bring the height up. The recovery anchor float could be inserted in the center of these rings.

For this current boat

I had a bow cover fabricated for the forward deck which was the right height that with the anchor puller

buoy in the center, it raises the bow cover enough so that when snapped

tight the cover is has upward tension in the center

thereby allowing any heavy spray not to pop the snaps and to run off.

After installing the 100 quart cooler in the bow, this cover is not

used much.

| This bow cover uses the anchor puller buoy which is secured in the center of the opening as a center support |

|

|

Corrosion Under the Convertible Top or Bow Cover Snaps ;

When I bought the used aluminum open

bowed boat, since I occasionally fish the ocean and have seen water come over

the bow, this could be disastrous in this instance, so soon afterwards I had a

upholsterer fabricate a bow cover. Since this aluminum boat was new to me

as a somewhat ocean boat, I noticed that the convertible top's male snaps had a

Nylon washer between the snap and the aluminum hull. I mentioned this to

the upholster. His comment was that they are not needed. OK, I found

out 3 years later that he may have been right, FOR

FIBERGLASS BOATS, but he did not know what he was talking about for

aluminum boats and of course he is now out of the upholstery business, but

taken over his dad's business drilling

wells.

I had a corrosion under about all of these new snaps. This entailed drilling all of them out, sanding down to bare metal, spraying zinc chromate on the aluminum, priming and then repainting much of the forward deck. After the painting was done, I used anti-seize compound on any surface that came in contact with the aluminum. This was coated on the new Nylon washer that went under the snaps and all the pop rivets before they were installed.

Then the open center of the female rivets were filled with Silicone caulking to again try to keep out any salt corrosion. Any bolt on fastener was also coated with anti-seize. And any bolt on unit was separated from the hull by placing sections of plastic milk jugs between it and the hull.

| Here you can see the corrosion under the paint around the snaps | More corrosion at this one | Here is the one on the left, showing all the corrosion that was scraped loose |

|

|

|

| Here all the snaps are removed & metal sanded | Here part of the aluminum is zinc chromate primed |

|

|

| Here the matching paint is covering all the damage | Here is the finished product, with the splatter paint finish coat |

|

|

I won't go in to a lot of detail in the above project, except one of the worst was to get a matching paint for this faded out original paint. When I had bought the boat 5 years before, I took a sample of the paint where I had cut out metal to create louvered vents and had a somewhat close match made in a quart size. Over time, this was paint was pretty much used up or had became scummed over and it needed to be slightly a lighter tint anyway. No big deal, just take the old can back and with the code on the bottom have more made in a slightly lighter tone. Problem was the person who matched it originally was no longer employed there and the new person was new enough that he could not decipher the code. And if he could, I would have to buy a gallon.

I covered about 6 hardware or paint stores in two towns, and either YES they could do it, but again in the gallon size, and they would have to do a rematch as their code was the new style and not compatible with my old code.

I finally found a Rodda Paint store. Same as above. I gave up and turned to go, mumbling something about doing it myself. The young man behind the counter asked if I had samples. Yes, and I had the original aluminum painted cut out metal with my somewhat matched paint on the 1/2 of it. He put it on his scanner, compared the two and said you need a tad bit of green in this. OK, I can do that, then he poured off some of this green coloring in a paper cup and said don't spill this on the way home. No Charge. WOW.

When I got home, I found that I was so low on this contaminated somewhat matched paint that I made up my own using a can of machinery gray and black to get it very near the matched original can. Now add the green tint. Looks great but I got a bit generous with his tint. A couple of days later I took the sample and my mixed paint in to him and explained my predicament. He asked if I had the can of paint in the paper sack I had placed on the counter. No, it was in the pickup. But in the sack was 4 large pieces of smoked salmon. This got him interested enough that he took my can and after about 3 tries, had a VERY GOOD match. And as before no charge. I later drove by and showed him his matching job. This year you can be assured that he got more smoked fish as a partial payment on my debt.

Then the problem of how to match the black/white splatter paint over the gray base coat. He said there was only one shop he was aware of that did that and 60 miles away. A bit of reading on the internet and I come up with using a narrow 1/2" stiff bristled brush and cut the bristles off to about 5/8'. Nylon proved to be better, being stiffer than hog bristle. Also you may have to thin out about 1/3 of the bristles.

Take a margarine tub lid and pour about 1/8" of the black paint into this lid. The paint needs to be as thick as possible (non-thinned). Wear surgical gloves and dip the brush vertically in the paint in this lid. Now holding the brush with one hand close to the intended surface, (about 4-6" for a full brush and down to 2" before refilling) use your index finger to pull back the bristles, letting the bristles snap forward, which gives a splatter type appearance.