|

|

Understanding Fuel Line Connectors for Remote Tanks

|

Many Outboard Fuel Quick Connectors May Look the Same, BUT

:

WELL, maybe until you try to interchange them. Here, I WILL

TRY to help straighten this out. When outboards went from smaller motor

with integral tanks to larger motors requiring more fuel and remote tanks, the

usual method of connecting them to the motor quickly moved into a quick

disconnect that needed to be leak proof, (both of fuel out and air in).

In the Horse Power race of those days, the need for more fuel

became apparent. And as the HP went up, the LARGE tank on top of the motor

died like the dinosaurs.

Fuel lines were originally 1/4" Inside Diameter, then as the motor sizes went

up, so did the need for a more steady ample supply, so

the lines went to 5/16", then finally to 3/8". In my mind, today, the

larger size fuel line is not needed, and maybe even a detriment for smaller, 30 hp and smaller motors, as older style small fuel pumps may not be capable of

sucking that volume of fuel.

Each company had it's own design with very few interchangeable.

And some changed over years, as technology also changed. There are at

least 3 distinct types. I for one, use a electric engraving tool to

identify the different brands, by engraving OMC, M, or Y etc. on the metal

latch.

Below are my preliminary findings, which MAY CHANGE as I delve into this

farther

Tank Vents --

Here, for fuel to be moved out the line from the remote tank, the tanks have to

be vented. The old way used on the smaller integral tanks was to on the

filler cap to have a small threaded bolt in the center that can be tightened

down to seal it from leaking, and this bolt loosened (allowing it to breathe)

for running.

Later the vent system was built into the fuel line coupler AT

THE TANK, which was accomplished by a SMALL spring loaded pin, that when the

coupler was inserted all the way, and locked in place, this pushed the pin in

enough to be an automatic type of venting the tank. Depending on the

manufacturer, various versions of this venting was used.

OMC -- Initially this company Evinrude, and Johnson used a Siamese fuel line, with one line pressurized into the tank from the motor and the other pushing the fuel from the tank into the carburetor. This started about 1959, depending on the size of the motor. Then about 1963 or so, a fuel pump was added to the motor that was activated off the vacuum side of the bypass cove, to where the fuel line went to a single line, that is still in use today. These connectors are the same for either end of the line (intake and output), however the primer bulb (in the middle of the line) which has internal check valves, (one on the intake and the other on the outlet), where the bulb is marked with a large arrow pointing the flow toward the motor.

Mercury -- Mercury had been making outboard motors since about 1939, but it was not until after WWII (about 1948) that they went to the larger motors. and the remote fuel tanks. Initially these fuel lines were connected directly to the tank, with a quick disconnect only at the motor.

Then

after 1989 they

were totally changed, to very similar to the common OMC type, but a close copy

of the Yamaha as for size.

In the photo below you see the older bayonet type Mercury connectors.

These fit the motor, many times the hose was connected to the tank without any

quick connector. These are a twist barb type, and in 2 sizes. The

small was used for motors 10hp and under, with the larger version for all

others.

| Here the early Mercury bayonet/twist connector | |

|

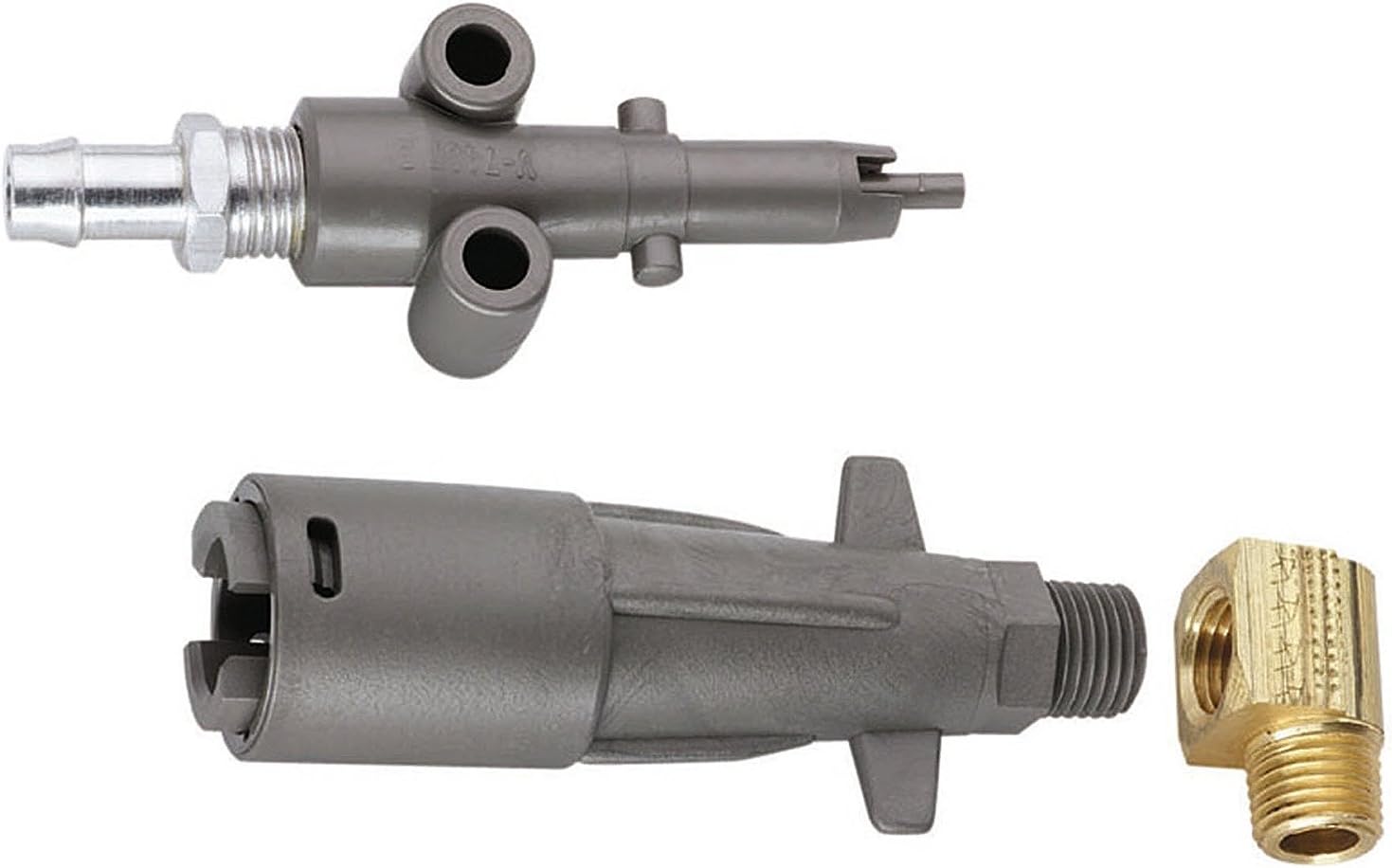

In the photos below, you see two connector fittings. The fittings on the left (both photos) are for the tank end while the one on the right fits the motor. The main visible difference is the location of the detent ball. The tank end has the ball closer to the end, while the motor end's ball is recessed .356". These fittings are usually a different configuration (depending on the manufacturer), usually the tank end is bulkier. The aftermarket Moeller tank fitting is 3033486-10 and sells for about $17.00.

| Here the later Mercury clip style connectors end view | Here the later Mercury clip style connectors side view |

|

|

The Mercury and the Yamaha use basically the same size latch and fuel

supply pin, AND will slide on, BUT the main difference between the two are the

distance from the end to the latch. The Mercury's length to the

latch is near .785", while the Yamaha is shorter like .532". They

will slide on, but not lock, or if it does, will be in the right location to

depress the fuel line plunger allowing fuel to flow.

Yamaha -- Yamaha

had been making motorcycles and snowmobiles since 1955. The word was

that when Yamaha started making outboard motors for import to the US in 1984,

that they copied many of OMC's patented ideas. They figured it was

worth the price to pay a royalty for a proven design, than to spend lots of

time, effort and money to develop their own, along with gaining considerable

amount of time to get production going, and with having a end product that would be well

excepted by the public.

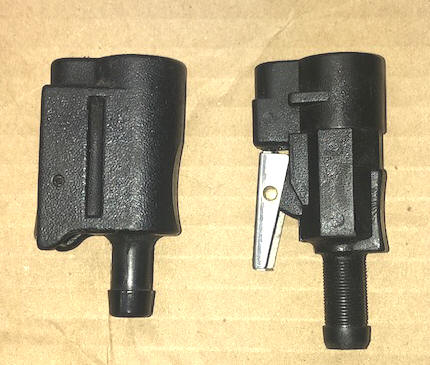

Honda -- Honda introduced their first outboard in the U.S. in 1967. 1985 was the first full line of four-strokes. Honda seems to have went a little different way, by using a common single push on tank connector with a Mercury style connector on the motor. This tank connector diameter is 11 MM. However the tank needs to be a cap vented style.

| Here the Honda, Suzuki & Tohatsu type line of connectors | |

|

Chrysler In the mid 1960s West Bend supplied motors to Sears' competition Montgomery Wards. In 1965 West Bend ended up selling out to Chrysler who became a major player in the world of outboards. In the 1980s, after Chrysler sold their outboard business to US Marine/Force, Sears once again offered private brand Gamefisher motors. Chrysler used the same type of quick disconnect fuel line as the Honda shown above. Their part number for the female end was #197787-3 (or Sierra #18-8062).

Suzuki --

Suzuki

Marine introduced its first outboard motor back in 1965.

In 1980, It

was the first

producer of outboard motors to use oil injection in their two-stroke engines.

They used a standard single push type similar

to the Honda, but smaller in

diameter, but on both ends of the line.

Their part number for the female end was #65750-98505

and uses a 3/8' line (or Sierra #18-8062). The male tank end

(.432" or 11 MM dia.) using a 1/4" pip thread, (or Sierra #18-8071).

Tohatsu / Nisson / Mercury -- They used a standard single push type similar to the Honda, but smaller in diameter.

Scott- Atwater

McCulloch

Clinton / Eska

Clinton introduced its first

Outboard motors in 1954. Through the years the Clinton Outboards have been

sold under many different brand names and through many different sales outlets.

The Eska Outboard

motor was manufactured from 1961 to 1987. In 1980 Eska, by then a

subsidiary of Talley Industries of Mesa, Arizona, purchased the Clinton outboard

motor product line from the Clinton Engines Corp. The purchase was to

consolidate area manufacturers to maintain a strong hold on the market which had

dropped due to the lagging economy. Some later engines were built by Tanaka of

Japan.

And then the EPA's new requirements,

where the new lines need a spray-less line connector

CLICK HERE

for the 2012 EPA fuel requirement for boats, which in

essence is the EPA's ruling of a

new safety venting system.

Now all the new

polypropylene aftermarket 6 gallon fuel tanks are required to be automatic

venting. A main criteria is that all fuel tanks have to be vented to

operate, therefore they have be vented either automatically or manually.

These new tanks have a spring loaded automatic vacuum one way venting system in

the filler cap. The EPA says this

fuel venting for the multitude of boaters out there is part of the US air contamination problem. BULL SHIT,

it's just like the doctors prescribing another medicine to

counteract the previous one's side effects.

with the Attwood #93516LP7 Primer Bulb and using

5/16" hose, and a Mercury Quick Silver 6.6 gal fuel tank, the primer bulb does

not have enough suction to lift fuel up This tank's pickup tube, even using only

14" of hose. This tube inside dia. is 10Mm. The fuel line is 5/16" inside dia. I

have tried 2 brand new primer bulbs, no difference. OK, I have found online, a

inline check valve, in different sizes, Ordered a 10MM and plan on inserting it

inline in the tank's pickup tube.

I have made every effort to ensure that there is no air leaks in any of the

fittings.

Is the weight of the gas inside this pickup tube so heavy that the primer bulb

cannot suck it? Does Mercury use a higher capacity primer bulb??

This Page Under Construction

Copyright © 2023 LeeRoy Wisner All Rights Reserved

Back to the Ramblings

Home Page

Originally

started 07-12-2023, Last Updated 07-17-2023

Contact the author

If you try t