| Stevens No. 12 Marksman |

|

Gunsmithing the Stevens

No 12 Marksman

Since these guns have been around for MANY years, often abused, broken with possible repair attempts, and now you get one that you want your grandson to have, this article is put together as a possible help.

There is very little factory documented information on this model, the best I have found is Single Shot Rifles and Actions by Frank de Haas published in 1969 by The Gun Digest.

The Marksman was less common than the popular Stevens' Favorite and other like size rifles, and was made between Circa 1912 and 1933 by the Stevens Arms Company, made in Chicopee Falls, Mass. It was a major improvement over it's smaller cousin the No. 15 Maynard Jr. (boys rifle) and replaced it in 1914. This model was made well enough and large enough to be called a "man's rifle".

About 1932 during takeover by Savage, the single shot rifles were discontinued giving way to the bolt actions models.

It was an intermediate model falling in price between the No. 26 Crackshot and the No. 17 Favorite. Prices were in 1932, the Crackshot $5.95, Marksman $7.95, and the Favorite at $8.95. Remember, that was a week's wages for many in those years!.

This model retains the basic Maynard principle in that it is a tip-up action, operated by an under finger lever. It also utilizes a simple take-down system.

The Stevens firm developed the .22 Long Rifle cartridge in 1887. The .22 Long Rifle remains the most popular cartridge in the world with yearly production varying close to 4 or 5 billion rounds.

These little rifles were made in .22, .25 and .32 rimfire, with the 22 being the most popular. My father purchased one in 25 rimfire when he was about 15 years old in about 1927 for $6.00. He figured the 25 Stevens rimfire would be a bit more powerful than the 22 at that time, and the price of ammo then was only a few pennies more than the 22 caliber at that time. During the first years of their marriage right after the Depression, he provided meat for the table with it.

Safety Features : This model has an external hammer and an under lever/trigger guard, which when pulled down, allows the rifle to hinge in the middle, exposing the chamber to automatically extract and load live round. Upon closing, it has a automatic hammer rebound, providing a safety situation holding the hammer off the firing pin until being manually cocked. The hammer must be manually cocked to fire each round.

| Stevens No. 12 Marksman |

|

Extractors : The only difference in the extractors are the height at the rear where they engage the cartridge rim. This extractor is made differently than most of the same era, having a round body and a 1/16" wide upper lip to do the work, which over time can get worn or broken. The only way to repair this is to use the older/front section and grind off the lip, then mill a 1/16" slot into the round section's rear, removing what was there. Now you can silver solder a new section of sheet steel into the location and fit it to the barrel sleeve and barrel.

This can get complicated if you have nothing as reference dimensions, (a good sample is helpful here). As taking off too much in a critical location will lead to having to do it all over again. And if you get your slot off in rotation only a minimal amount, that throws off your fitting as the top of the round forward section, is flat. Also the hook shaped notch in the firing pin is what the lip of the link engages into to retract the extractor, again good alignment needed here in this repair. Then an initial close hand filing on the top, with using a 22 LR chambering reamer to cut the final case/rim cut.

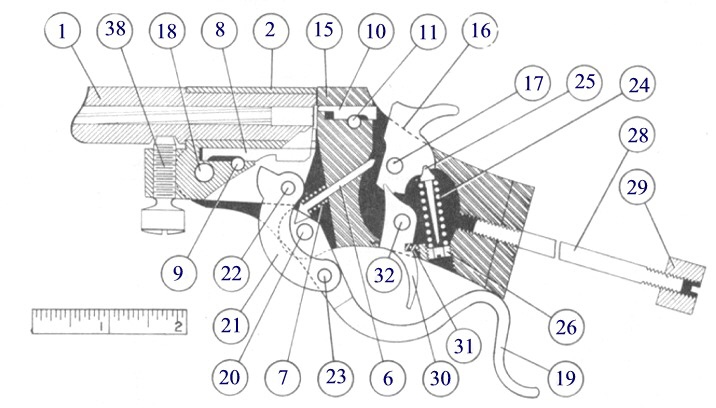

Firing Pins : There are two firing pins, one used for both the 22 and the 25, while the 32 is slightly different. The smaller calibers, use a firing pin with a center protrusion, while the 32 has a offset tip on the top allowing for the larger diameter rim. These firing pins are designed with no retractor spring and have a slightly radiused tip and limited protrusion by the notch in the firing pin and the retainer pin (11). This limited protrusion and the rounded tip prevent the firing pin the not get caught under the extractor on opening the gun.

In the illustration below the firing pin shown is for the 32RF.

Barrels : There was only one barrel length available for this model which was around 22". Most of these barrels after 100 years and in all likelihood could not have been well cared for, the chambers could be rusted to the point they can get hard to extract, or the whole bore is bad. These guns can be a candidate for a reline. However I must say most all of these Marksman models that I have seen were more well cared for than a lots of the others.

In relining a barrel, the old bad bore is drilled out to about 5/16", a new 5/16" diameter rifled barrel liner is inserted, epoxied in place. It is then rechambered and the extractor slot is cut. If the person doing this stops the drill just short of the muzzle, then shapes the front part of the liner to match the drill's cut angle, when the job is finished, it is about impossible to tell what has been done. This then gives an old worn out barrel new life, is easier and cheaper than making a new barrel, plus it maintains the old charm.

True Takedown : These models utilized the barrel shank, (#2) in the exploded view illustration above, bored out to accept the rear section of the barrel. The barrel was held in place by a large headed knurled screw inserted into the bottom of the barrel shank(#38), retaining the barrel aligned and in position. This barrel shank remained on the receiver when the barrel was removed and could actually considered by some as a removable part of the receiver.

Calibers : The calibers available were 22 RF, 25 Stevens RF, and 32 RF. The 25 and 32 ammo may still be available from Navy Arms as imported from Italy (not economical, but available).

Sights : Here you will not see factory adjustable sights, simply dovetailed in front and rear sights. And in reality they allow the shooter to be pretty close for elevation on these calibers, with windage by drifting them sideways.

Caliber Conversions : It is not practical to convert calibers on this model UNLESS, you have a 25 AND can find a decent used 22 caliber barrel. Trying to go from a 32 to a 22 would not be practical as the firing pin hole in the breech of the 32 is located too high, where the difference between the 22 and the 25 is so close that it should not have a misfire problem.

Screws : Screws for many early firearms typically were not made of hardened steel and could wear or bend easily. However it seems that this model was designed better to mostly eliminate that issue.

Hammer Spring : Here a coil spring was utilized, that being inserted from the bottom of the frame behind the trigger and held in by a threaded bushing, that could be adjusted if need be.

Stocks : Here, the stocks were walnut as compared to beech on the smaller more economical models. The butt-stock was held in place with a long stock bolt under the buttplate. The forearm was held in place by a single screw into the bottom of the barrel. The buttplate was made of black bakelite.

Serial Numbers : Any number or number/letter appearing on the receiver is probably not a serial number, but a assembly number.

Common Wear Faults : Here, the most common wear seems to be the link screw (#23). It being smaller than the others and subject to more abuse/pressure in closing the firearm over time. At the same time the link pin (#22) could get slightly worn and may need to be replaced, however these seem to survive better than the link screw. Or the pivot hole in the link where the screw goes will get worn elongated, allowing the same problem.

When when the above happens, the

action will not lock up tight, lever can drop of it's own weight, pinching a

finger if in the wrong place (ask me how I know).

The other symptom is misfiring.

What happens here is since the lever can not

now pull the barrel down into the receiver far enough, the firing pin now can

not hit the rim of the cartridge high enough to ignite the priming compound in

the rim. If this link gets worn enough, trying to weld up the worn

part of 1/2 a 1/8" hole and filling/milling out to a questionable original location, may

contribute to ulcers for a gunsmith. The most logical repair is try to

find a used (better condition) link.

Another issue is with very little mating

surface at the rear of the receiver for the wooden stock, lots of times you will

see the stock badly cracked where it joins the receiver.

Reproduction Parts : Few companies delve into this model because of its scarcity. However Jack First Inc, does make a few of the most normally worn parts. Prices are not cheap but the quality is excellent.

This page under construction

Copyright ©

2019 - 2022 LeeRoy Wisner All Rights Reserved

Back to the Main Ramblings Page

Originated 12-20-2018, Last updated 08-24-2022