|

|

Starting a 2 Cycle Outboard Motor That is Resisting Your Efforts |

|

Johnson, Evinrude, OMC, outboard motor, outboard motor repair, outboard troubleshooting, 9.9, 15 hp, year of manufacture, water pump, carburetor, long shaft, 15 hp conversion, sailmaster

|

|

Starting a 2 Cycle Outboard Motor That is Resisting Your Efforts |

|

In this article I will not deal with any specific make of manufacture or model, but just what to look for and in close proximity of and what order to look at. Many times you enter into a situation where someone is posting information on a on-line message board, there seems to be a lot taken for granted as to "Existing General Knowledge" as related to outboard engine repair. In this article I will try to explain as much as possible in very simple language, however this is not possible without using the proper terminology. We will be dealing primarily with small 2 cycle motors up to about 10hp here, but the principal is the same for all sizes.

First off let us assume that you have at least a small amount of mechanical knowledge. If you do not know the difference of a #2 Phillips screwdriver from a 8" adjustable spanner (Crescent) wrench, and you are not one of those persons who should not be left alone with a pencil sharpener or even sharp knife. If you do not have the ability to read and at least comprehend even the least bit if information, then you probably had better take your problem to a professional then make a deposit into his bank account for his experience. You can invest in outboard repair manuals and books, spend some time digesting what they are saying as to what they really mean by looking at your motor, do your own wrenching trial and error repairs. I will however 98% guarantee that you will NOT have instant gratification the first time around.

Here it is ; Let us assume that you know nothing at all about the motor staring at you. First thing I would do is to pull the starter rope to see if the motor is not seized or frozen up in some manner. If so, it could be a rusted, blown or seized piston, or even a frozen gearbox. Any of the above, would indicate that way more diagnostic and repair work would be required than a simple (or not so simple) just putting new gas in and getting it started situation. This would be the first of a check-off list as to this motor possibly being a candidate for the junk pile.

Try to find out some sort of history about it if at all possible. Now also take into consideration the source of your information. If the person just happens to be selling it, many times, they stretch the truth more than as little (remember they could also be fishermen). If you can come up with any information at all, this may help you instead of doing all your own detective work. When I say detective work, it is just that, you need to know what requirements are to make the engine run and be able to go thru a check-list. One small overlooked item may be the key to getting your motor to function. And remember just because you found pieces or parts installed in a certain way does not mean that this is the proper installation if someone has had a wrench on it before.

Inspect the motor, the general overall condition can give you some indication as what to expect. Has it been USED or has it been ABUSED? There is a distinct difference here. Are any parts missing? Can you see any new gasket sealer at some parts joints of the block or under the head? Has it been recently repainted? The above two are indicative that someone has been working on it, WHY is the question you need to ask now that you have been delegated to get it running since apparently they could not? Here we are making an assumption that the motor is not seized up in any manner be it pistons or gearcase. And all that is needed is much Tender Loving Care to get it purring again.

How Old is It ? ; If the above motor happens to be a pre-WWII motor, or even a few years later, like up to mid 1960s, parts may well not be easy to find. You will most likely need electronics, like coils, possible points (however most points can be cleaned up), or condensers (condensers rarely fail however).

But if you need help, try these websites. http://www.vintageoutboard.com/ http://www.penn.itgo.com/ http://www.laingsoutboards.com/

Try to Start it First Off ; There is no need do a lot of preliminary tear down if the motor does not need it. You will be amazed that even with motors sitting for years, with new fuel, clean the plugs, and maybe a squirt or two of starting fluid that how many of them will start, maybe not run well, but they will run. This sure saves a lot of unnecessary work on your part, as it eliminates a whole lot of possibles, and may also give you some valuable clues as to what is not functioning.

Requirements / Methodology ;

ANY

internal combustion engine has NEEDS 3 simple but main requirements to run, they are

Spark,

Fuel

and

Compression.

All the above

being said,

there may need to be some fine tuning of the first two to make it run in

a manner where it can be used efficiently.

Spark is one of the main requirements for an engine to run. The older motors will have a Magneto type ignition. In these, spark is generated by the flywheel magnets rotating around a coil of some sort. This generates electricity, that electricity is transferred to a condenser and then to a set of points. From the points/condenser/coil, the electricity is magnified and intensified then sent thru a insulated wire to the spark plug which when the motor is timed right and the compression of the upcoming piston compresses the fuel, the spark plug creates a intense electrical spark (fires) because of the points opening, igniting the compressed fuel, creating combustion, starting the motor running.

Motors newer than about 1978 (depending on manufacturer and model) moved onto electronic ignition, eliminating the points, using a new Capacitor Discharge system and a power-pack. This system produces a stronger spark and usually a smoother idle/trolling speed. However you may see some of the smaller 2 to 4 hp newer motors still using the magneto ignition, probably because of the expense of the electronics.

We will be dealing here mostly with non electric start motors, simply because that narrows down many other things we will not need to look at. Any electric start motor should be able to be started using a rope, (unless the motor is so large you can not physically pull it over). And even if it has a electric start, all that I am aware of do not need the battery to run the motor, just for it to utilize the electric starter and generate electricity to supply power to any electronics you have aboard. That said, some of the newer motors, even the 4 stroke Yamaha T8 electric start/power tilt does not have a manual starter.

(1) Spark ; One simple way to check if the plug is firing is to remove the, or all spark plugs, (makes for easier cranking). Reinsert one plug into the spark plug wiring boot and ground the threaded end of the plug to a bare place on the motor, (usually a head or thermostat housing bolt). Pull the starter rope while watching the location of the electrode on the spark plug, (many times here is where a helper comes in handy but do it in a shaded area). This is kind of the redneck method and does not really give the condition of the electronics, but it can give an indication if you are getting spark without going to farther testing. Change to the other spark plug wire if a 2 cylinder and redo the above test to verify it is also working or not.

The spark should arc from the over-arm electrode to the center post of the spark plug in a white or blueish color. If the color is orangish, there is something weak in the system. It may run, but may well be hard starting.

It is however recommended that you build or purchase a spark tester. These can be set for specific distances, which in turn will give you some indication of the of the performance of the ignition system. If the spark does not jump the suggested distance or is the wrong color, you need to do something about it.

The recommended spark gap for testing does vary with different ignition systems as follows.

It is suggested to do a spark test first. Get an "air gap" spark tester and set it for 1/4" for magneto ignition (points and condensers) or 7/16" for electronic ignition (CDI). The ignition spark should jump the appropriate distance and be a bright blue color. If it tests good on both cylinders, do a compression test. (you can do that without a compression tester by slowly pulling out the starter cord and feeling the two resistance spots through the cord). If it "feels" the same, it should be ok. Of course, the best thing to do is to get a compression tester and get accurate results. If those two things test OK then, the carburetor is probably dirty inside and will require a thorough cleaning and/or a carb kit. But start with the ignition test first and be sure you have the correct spark plugs and the gap is .030 on about all; outboard motor spark plugs.

If you are working on a older motor that uses the Magneto type ignition, if you are not getting any spark to the spark plugs, you need to back up, pull the flywheel and check the internals for loose or broken wires. Pull the points, clean them with lacquer thinner, clean the contacts with a point file, reinstall and adjust them (usually to .020"). Check the wires leading to and from the coils and condenser for looseness. If the insulation on the coils are cracked or peeling off you can be pretty well assured that they are bad.

However you can check if the coils are good by using a simple multi-meter which usually sells for about $20. But it has to have a Ohm resistance scale on it which you need to set in it's highest setting. With the meter set at Ohms, short out the black and red wire probes, the needle should climb, there usually is an adjustment knob to calibrate this reading when shorted out like this, if so make it read all the way. Now the coils have a primary and a secondary winding. The primary winding will have the heavier wire, using the probes, ground out the black and touch the outgoing wire to the points, you should not get a reading. Now leave the black probe on the ground and with the red, touch the wire going to the spark plug. If it reads near .6 the coil should be OK.

If you get a mid to high speed miss and have concluded it is one cylinder, look at the coil. Someone may have "worked' on it before and flopped the coil so that the output wire is down to where it shorting out to the timing plate when the motor is revved up. Remove the coil, re-rout the wire or flop it end for end.

Condensers are not as easy to test unless you have a special tester, however you may be able to take them to a automotive supply store and have them test these parts. This test places a charge into the condenser and then registers how fast it disperses this charge. Each motor is designed for a specific condenser output, but they should be able to at least come up with a guestimate if the condenser number is missing. Condensers on the other hand, if they are still available are rather inexpensive, however some of the imported ones longevity is not as reliable as the older ones.

In talking to an experienced motorcycle mechanic that was well accustomed to seeing older magneto type ignition bikes, he related that (1) most condensers are replaced simply because the cost is low as compared to labor for trouble shooting the electronics later if it doesn't run. (2) His method of telling if a condenser is bad, is look at the points, if they are pitted badly, it is because of a failing condenser. However if the points look evenly worn, just clean them with lacquer thinner, drag non-waxed paper like a brown paper bag thru the contacts a few times, adjust them and 99.9% of the time it will run great.

The

spark plugs are the thing that is screwed into the head of the motor that

actually creates the fire to ignite the fuel. They

consist of a metal threaded portion with a ceramic insulator that has a metal

center that the insulated wire from the coil attaches to. They need to be in good enough condition to transfer the spark from the

coils to the combustion chamber and ignite the fuel. Also you have to use the

right spark plug, not just any old plug will do. Spark plugs are made in

different size threads with different thread lengths, called reach and in

different heat

ranges. It would

be very detrimental to a piston if you tried to use a 1/2" long reach in a motor that

was designed for 3/8". Plus the piston surely will bottom out against the plug

blocking any further movement making the motor impossible to pull start with the starter rope.

Standard magneto ignition = 1/4" gap

Battery Capacitance Ignition = 3/8" gap

Capacitor Discharge Ignition = 7/16" to 1/2" gap

Also if you get intermittent spark or only firing on one cylinder, you may have a bad connection at the boot end where the boot goes over the spark plug. Pull the boot straight off the wire and cut off enough of the wire (about 5/16") and push the plug's wire coil back into the wire, then reinstall the boot.

| Notice the the arced, burned wire at the location of the coil's contact point |

|

Another thing, rather rare occurrence, but it is possible that your kill button may be defective. This would be more likely to happen on the 1987 and later motors using the "Man Overboard Kill Switch".

If you are working on a motor that has external coils and you are getting a situation where the motor dies when it warms up, to simulate this in a barrel, take a hair dryer and heat up the coil pack while its running to see if there is any change. If so, then you have identified a defective coil.

Spark Timing ; One thing to understand, is that you can get spark to the spark plugs but it will not fire IF the flywheel key is sheared. This could allow the flywheel to be rotated out of the desired location enough to throw the spark timing off to where it may not run right, if at all.

On

two stroke outboards, without some means of advancing and retarding timing and

simultaneously controlling the carburetor, the engine simply would not idle well

or transition well from low to mid and high speed. Outboards are

expected to run well from a slow idle to Wide Open Throttle. Most

other two strokes (chainsaws, dirt bikes etc) are tuned/timed to run best at or

near WOT.

Ignition timing and carburetor throttle control are used to

control engine operation on every engine regardless whether it is a two or four

stroke outboard, carbureted or fuel injected.

That applies to all

engines. Timing is advanced automatically in the distributors of

many auto and other 4 stroke engines. Both rpm and vacuum are used for the

auto-advance. Doing it manually in outboards saves weight and complexity.

Power output would be greatly reduced without it.

(1A) Spark Timing ; Occasionally you will find that the flywheel key has been sheared allowing the fly wheel to slip past it's intended location. If this is the case, the spark timing will not be correct in that the flywheel magnets will not be in the proper location on the crankshaft to give the spark off the coils to the spark plugs at the proper time and it will not even sputter.

(1B) Spark Timing ; The twist grip throttle handle has to be aligned so that the timing plate under the flywheel is somewhere close to the position where the motor WILL start. That is why the twist grip throttle has marks on it lining up with words like slow, start and fast on the handle shaft. If in doubt, there may be some slack in the handle linkage, move the twist grip to the faster position than slower.

It is even possible for the motor to "kick back" the rope starter when you try to start it. If this is the case, check your flywheel key, could be it is sheared and allowing the flywheel to slip on the shaft, which will put your engine out of time.

(1C) Spark Timing ; The bulk of these old motors may be made before about the mid 1970s where the ignition is a straight magneto setup with points and condensers, compared to the newer electronic ignition. The flywheel will usually have to be removed to work on this ignition. There is a set of points and a condenser for each cylinder. The points need to be set at the manufacturers recommended gap which is usually .020". The point setting is usually stamped on the armature plate under the flywheel, and or on the inside of the flywheel, so if you remove the flywheel you can see this setting. These flywheel pullers do not pull from the outer edge, but from 3 bolts screwed into holes in the top of the flywheel.

| Here is one style of flywheel puller in place |

|

|

Some keys are just a rectangular piece of steel about 3/16" square, while others are a 1/2 moon shaped (or Woodruff key) and about 5/8" across the widest part. For the Woodruffs, the radiused key is positioned into a matching radiused slot in the crankshaft. Most of the outboard motor flywheel Woodruff type keys are special to the outboard system and the local hardware store ones will not fit properly.

These keys have to be in their respective slots and deep enough for the flywheel's slot to mate and be able to be tightened down. If the Woodruff key is rotated slightly, (up or down) the flywheel may not seat down tight on the taper when the flywheel nut is tightened. You may have to remove the key, remove any burrs on it, replace it in the crankshaft slot so that the slot in flywheel will slide down and align otherwise the flywheel will not be seated and will wobble if rotated. These keys are made of a soft metal so that they will shear if the motor happens to come to a sudden stop as to not bend or ruin the crankshaft.

| Illustration out of an OMC manual showing the key in the crankshaft |

|

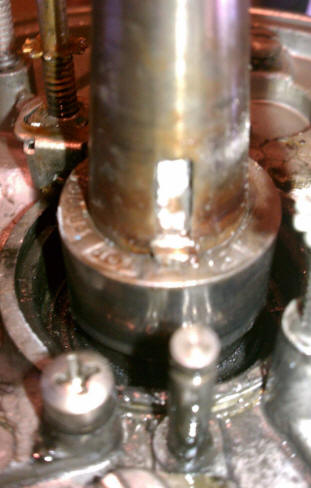

If one of these keys become sheared off like shown in the photos below. The flywheel will probably still be tight enough on the crankshaft taper for the flywheel to rotate, but your spark timing will be off enough that the motor may not start. The photo on the right is from a magneto ignition, hence the breaker cam at the very lower part of the key. Later electronic ignition will be missing this breaker cam, so the key will more open visually.

A sheared key could be caused by the flywheel nut not being tightened down tight enough, or the motor may have hit a solid object while going at a fast speed, suddenly stopping the motor, but the heavy flywheel kept on rotating, shearing the key off.

| Sheared flywheel key, with part of it still in crankshaft | Here is the sheared part of the key that WAS in the flywheel groove |

|

|

To remove a broken key like this, the sheared off part will usually fall out of the flywheel. But getting the other part out of the crankshaft radiused groove without ruining the slot may be challenging. If it is a magneto type ignition as seen above, the breaker point cam needs to be removed. This can be pried upward and off the shaft, however the burrs left on any of the remaining key may have to be dealt with.

What I have found that works good is to grind down the blade of a medium screwdriver. Grind just wide enough and to a chisel point, but with one side of the chisel steeper than the other. The more sloping side pointed inward, trying to get that point started UNDER the upper edge of the broken key. As you drive it down, try to use it as a fulcrum prying the key outward at the top first. You will probably ruin what is left of the key in the process. If you do mar the sides of the slot, try to clean them up, if the bottom, try to clean that also, but if you can't, then just using a flat ended punch, pound the metal back down as usually there is clearance on the outer part of the key to the flywheel slot, so no real importance here.

In setting these points, advance the twist grip throttle to FAST as far as it will go. The #1 piston should be at Top Dead Center. This can be verified by pulling #1 (the TOP) spark plug and by using a flashlight, rotate the crankshaft clockwise until you can see the piston come up, go slowly and backtrack, then rotate it clockwise again to where it is at the top of it's movement This is now Top Dead Center. There may be the word TOP or SET on the timing cam ring that is on the crankshaft protruding above the timing plate. Your points rub bar should now be at or near the TOP location. Without changing the twist grip location, move the crankshaft to the SET position. Set the #1 points (usually on the RH side of the motor) with a feeler gage at .020, (if that is the setting so marked) rotate the crankshaft 180 degrees if a 2 cylinder and again with the rub bar at SET, repeat the setting for #2 piston.

Sometimes on the older and smaller motors there will not be any TOP or SET markings. If this is the case, then with the piston in the furthest up position, rotate the timing plate until the cam is in it's largest location holding the points apart. Set the points at this location.

If the motor has sat for a while the points may have gotten oxidized. This can be usually remedied by running a point file (yes they still sell them at automotive supply stores) thru the point openings to freshen up the contact metal. A normal file is too thick and usually not hard enough to touch the harder point surfaces. If you do not have a point file, then some fine emery cloth pulled thru the points may remove some of the oxidation.

If you encounter hard starting on this series of motors, you could try opening up the points a bit. Some "Old Timer Mechanics" word is that to make those ignitions work a little better, these mechanics would open up the points to where it ran better, even about .030" as the coils lost some of their power. This older ignition using condensers, if they start to break down internally, the motor can start and run for a while, but when things warm up, the condensers and or coils can begin to short out internally with the motor may dying. You can crank until you are blue in the face but it refuses to start. Let it set for an hour to let these components to cool down, contract and eliminate the internal shorting. It MAY then restart. Time to change condensers or even coils.

(1D) Spark, or Lack of It ; If you have done most of your suspected repairs and still no fire when you pull the starter rope, you may try pulling the starter rope in the dark of night, as any leakage or jumping of spark will show up way better in the dark.

If you finally get it to run, it is a 2 cylinder but it is laboring and or has no power. You can very likely have a motor that is running on only 1 cylinder if it is a twin. Here for some reason you have a problem, usually somewhere in the electrical system. A spark plug is bad, the wires have a bad connection somewhere, or the ground wire somewhere has corrosion under it, even a bad coil or power-pack. This should have been caught in #1 of this section. If you get here then the simplest test is to, while it is running, pull one spark plug wire at a time. If it does not make any difference in the running when you say pull the top (#1) plug wire, that will be the dead one. If you reconnect it and then pull the bottom (#2) wire it will die. BINGO you have found the culprit. Now only to find out why.

(2) Fuel ; The other basic is fuel. It needs to usually be 87 octane gasoline, AND be clean of debris, and NOT old or stale. Stale meaning sat for years and has deteriorated with a foul varnish smell when the cap is removed. If you leave old ethanol fuel in the carburetor and don't run the motor dry, it can create a gooey mess inside if left over the winter.

If you are trying to start a motor that has sat for a while and try to squirt fuel into the spark plug holes and or carburetor, this is the place NOT for "if a little is good then a lot is better". If you get to much in, the fuel will drown out the spark plug electrodes and you will not get the spark plugs to fire.

The fuel tank HAS to be vented in order for the fuel pump to suck the fuel into the motor. Some of the older manufacturers metal gas tanks may have a internal automatic vent system. Others require that you slightly unscrew a vent screw, usually on the filler cap. If this vent is not loosened, the motor may start, but will soon die when it can not suck new fuel into the carburetor. The later tanks made after 2011 are also vented somehow (I have not been able to determine this as of yet as it was designed by EPA engineers). They were convinced that us outboarders were contaminating the atmosphere when we loosed the vent cap of our fuel tanks.

Another thing to try is elevating your tank well above the engine. A couple of feet higher. At that point you have a gravity feed fuel system once the motor is started and it should eliminate any fuel pump concerns.

Check the fuel tank for varnish. This will be a gummy or hard deposit left after the gasoline evaporated and has dried up. Just pouring new fuel into an old contaminated tank is asking for trouble by sucking dirty fuel into the carburetor. One thing I have done in the past for this condition is to purchase a pint of Xylol or Xylene (same product), which is a highly potent paint solvent/thinner works better, cleans the inner tank very well. A quart costs about $6.00, just pour in enough to cover the hardened residue. Next a large hand full of ceramic tumbling stones were added, (a substitute would be washed pea gravel) replace the cap and shake the tank in all directions for a few minutes each time I pass by it in the shop. Note that some internal hardened residue may extend up on the insides also, if so, lay the tank on it's sides occasionally to soak as well. Let it set and shake for as long as it takes to soften the debris. Overnight you will see things start to happen. Inspect with a flashlight, keep shaking. Flush it out, repeat if needed.

The fuel lines may also need to be replaced or at least cleaned. A fuel filter may be needed in the line before the carburetor. The small plastic fuel filters used on lawn mowers would be one to look at.

Most of the motors made before mid 1960s used bronze bearings in the connecting rods. On these motors the fuel needs to a richer oil ratio of 25 to 1 otherwise the motor may be under lubricated and seize up. NOT GOOD. However using this rich a fuel/oil mixture may contribute to fouled spark plugs more often than the later motors that recommend a lesser amount like 50 to 1. But do you want a motor that is running or blown up?

(2A) Delivery of the fuel ; This is where things could start getting complicated, as the fuel needs to be transferred from the fuel tank, to the fuel pump, then into the carburetor.

If you happen to be working on a smaller motor that uses an internal tank on the motor, life can be simpler as you will not have a fuel pump or all the associated fittings and neoprene lines.

If you can not readily decipher whether it is fuel pump or carburetor problems, make up a small separate gravity feed fuel tank. In the photo below you will see a 1 quart oil bottle with the cap modified to accept a 4' fuel line with a female fuel coupler for the motor end. This bottle has the bottom cut out and a hole drilled on one side to facilitate hanging it by a cord to a nail on the wall behind my test tank. By using this as a gravity feed, if the motor runs fine, it then very likely has to be a fuel pump problem.

It also works great to decarb the engine with a RICH mixture of fuel and SeaFoam as mentioned later in this article.

| Small gravity test fuel tank |

|

|

You can check your fuel pump for functioning by disconnecting the fuel line from the pump to the carburetor, pull the starter rope as if you were trying to start the motor. You should get squirts of fuel (each time the piston comes up) coming out of this now open line that was going to the carburetor. If not, then the fuel pump the problem or is at least part of the problem.

Anywhere there is a connection in a fitting or rubber tube is a potential air leak up to the fuel pump, this will break the vacuum from the tank to the fuel pump. These connections have a male and a female end, either could be failing. The male end (on the two prong styles) uses one as a guide and lock, while the other is connected to the fuel tank/line and uses a female connector. Inside this is a Neoprene O-Ring to seal onto the male counterpart. This O-ring can get worn causing a loss of suction, OR the male end (which has a protruding needle), this needle needs to be depressed by the female end to open the check valve. Of the two of these couplers, the female would probably be more likely to fail.

Also the fuel pump will have to have some means of activation. This is usually thru a small fitting or passageway into the crankcase cavity. In operation, being a 2 stroke motor, the crankcase, on the backstroke, or the intake manifold creates a osculating vacuum/pumping action, thereby giving a pulsation between sucking and exhaust. This osculating action of pressure/vacuum operates the fuel pump's internal diaphragm. Once the fuel is sucked into the fuel pump there are small check valves that do not allow the flow to be reversed, which now allow the fuel to be pushed into the carburetor. There may be a fuel strainer of some type that has to be clean and functioning.

The fuel primer bulb (the rubber football shaped bulb in the middle of the fuel line) is used only to initially suck fuel from the tank and up to the fuel pump. In operation, squeeze this bulb a few times until it becomes hard, (indicating that it has sucked fuel up to the fuel pump). At that point, it simply becomes a section of the hose and should not stay solid as when it was initially pumped up. However since there are a intake and outlet check valve inside these bulbs, it is best to lay it horizontal when the motor is running. The reason here is the fuel has to pass through these check valves which utilize very light internal springs and you should not compound the suction by leaving the bulb vertical.

(2B) Once the fuel is at the fuel pump it must then be transferred to the carburetor. A leak here may not be as critical as on the other side, BUT it could also create a fire hazard.

(2C) The carburetor needs to be clean and adjusted somewhere near properly for it to start. After it starts, warms up and is running at a near idle, the idle adjustment screw may need final adjustment. Cleaning the carburetor does not mean spraying carburetor cleaner or Sea Foam into the throat, or even doing this while it is running. The carburetor really needs to be removed and physically cleaned and or soaked in carburetor cleaner.

Occasionally you may find a idle or even main jet needle, if the motor is old enough to have the adjustable main jet, that will unscrew by itself when the motor is running. There will be some form of retainment on these shafts, be it a spring around the shaft or a packing nut, possibly a rubber seal insert into the front of the carbs threaded needle hole. If the packing nut style, then it is a simple task to tighten this nut in, putting more pressure around the shaft.

(3) Compression ; The piston rings and cylinder bore have to be good enough condition to suck the fuel from the carburetor and into the motor. Most small motors up to 50hp will be a 1 or 2 cylinder and the compression is not usually high as compared to a automotive vehicle. I have seen on new rebuilds where compression was 110# -120#, while on other used but running motors 75# was normal. If it is a twin, the two cylinders do need to be close in compression, meaning one can not be 85# while the other is at 35# to operate effectively. This would indicate the low one may well have a blown head-gasket, broken rings, or a scored cylinder, even a broken ring gland in a piston, any of which would seriously hamper the starting, much less running of a motor.

However if the motor you are working on has set for some time, which will dry out the internal cylinder walls, and you pulling it over with a rope type starter, your compression reading will normally be lower than if it was running right up to the time you acquired it.

Compression tests are sort of like taking aspirin. . . Every armchair mechanic wants you to do one, no matter what the other symptoms. Compression testing is one of the tools that may help diagnose a problem, not the cure. Like if both cylinders of a 2 cylinder motor are low and exactly the same, you may have a blown headgasket where pressure from one is being blown into the other. Or if the readings are low, like 30#, you may have worn rings. or even rings that are stuck in the piston ring grooves, which will lower compression and make for hard starting or deter efficient running.

See #9 at the end of this article as to something to do after you get it running.

(4) Try to Start it Again ; With these tests performed, try to start the motor by opening the fuel shut off or pumping the fuel line bulb (if it has a remote tank) until the pump bulb becomes hard, indicating the carburetor bowl is full and the float valve has stopped any more fuel flow into the carburetor. When pumping the bulb, the bulb itself needs to be pointing vertically until it becomes hard. This is because internally in the bulb is a inlet and a outlet check valve, these utilize very weak springs so that when during the normal running of the motor, fuel will flow with minimal restrictions. But on the initial pumping if you leave it horizontal, the check valves may not function well enough to pump up a dry carburetor. Once the bulb is hard, do not keep trying as you may just be pumping raw fuel out a carburetor overflow.

Pull the starter rope as vigorously as you can. If it does not show some form life within the first 6 pulls or so, you may have to pull the spark plugs, squirt a couple of squirts of mixed fuel into the spark plug holes. Try pulling again. If you do not get it to fire, you will have to go over the above items AGAIN. Some people use starting fluid for this, but do not overdo the starting fluid as it does not have any lubrication and if continued usage it could damage the rings/cylinder walls because of lack of lubrication. What you are trying to determine here is if the fuel pump is malfunctioning. Ideally you should be squirting the fuel mix directly into the carburetor or it's breather unit.

These old motors will usually need to be ran with the choke partly out until they warm up. Each motor is unique to itself, so you may have to find a sweet spot that it likes until it warms up.

(5) Still Won't Start ; If You have tried everything and still no fire. If this is a motor that someone may have mechaniced on before, but gave up on, there is one other thing to look at. Pull the carburetor and intake manifold and look at he gaskets. There is a gasket on each side of the reed valve plate behind the intake manifold. These gaskets are very similar. If someone had the engine apart and installed the outer gasket on the inner side, the openings for the reeds is smaller, which could hold the reeds closed, not allowing any fuel to be sucked into the motor. This is not an easy chore as there is one bolt under the manifold and very close to the lower cowling pan, that with the powerhead still in place will be only unscrewed one flat of the bolt head at a time.

In relationship to the above, if you get a motor that will run, bit not good at an idle, and everything else is right, the same may be part of the problem, but with part of the proper inner gasket folded in, holding a reed from opening completely.

(6) One More Thing ; Have you heard of an Anti-Siphon device? In accordance with industry safety standards, late model boats equipped with a built-in fuel tank will have some form of an anti-siphon device installed between the furl tank outlet and the motor's fuel inlet. This device is is basically a small inline check valve that in use here is designed to shut off the fuel supply in case the boat capsizes or is involved in an accident. Quite often, the malfunction of these devices can lead to the owners replacing the fuel pump in the belief it is what is defective.

You will also find these on boats that use both a main motor and a kicker motor for trolling where they both use fuel out of the same tank. Here one of these devices would be installed so the larger motor does not pull fuel away from the smaller motor, creating a hard to start small motor when the need to start it arises.

(7) Success ; OK, now you have it running. Is it spraying water out the "pee hole" or a watery mist out the back side of the upper cowling if it is this early type pre 1977 or so? If not, watch for the motor overheating. The pee hole may just be plugged. The easiest location to check this would be if the top of the block under and behind the flywheel, if it gets so hot you can not touch the head or top of the block for longer than a 5 -10 seconds or the paint smells like it is burning. NO COOLING WATER GOING THRU THE MOTOR, SHUT IT DOWN ASAP. More on this problem listed farther below under water pump repair.

You probably may need to adjust the carburetor idle needle valve knob because someone may have already tried. Most of these have some sort of a lever or rotating knob for this idle adjustment. When you finally get it set where you want, mark this location somehow for future reference.

If the motor is to be used for trolling, you may have to fine adjust this idle (or slow speed knob) to a position where the motor runs smooth enough for intended purposes. Make this adjustment 1/4 turn at a time and let it run for a minute to allow the fuel in the carburetor to be metered by the new adjustment. Usually screwing this knob in (clockwise) lessens the amount of fuel delivered to the engine. When you reach a point that the engine lugs down and dies, back it up slightly then you should be there. However if in your adjustment if you go counterclockwise with the motor coughing and dies, this is usually an indication it is too rich, so go the other way.

Some older carburetors also have a high speed adjustment knob. This can only be adjusted in a test tank or on the boat when the motor is running at full throttle. By adjusting it you will soon be able to tell if the motor is running faster or slower and be able to select the proper setting required.

(8) Repair Water Pump ; OK, this is not really starting related, but you may not be able to run it for long if the water pump is inoperable. You may have found that no cooling water was coming out of the motor. A few older motors were air cooled, usually they will have cooling fins on the powerhead. Even some of these air cooled motors will have some form of water cooling to keep from burning the paint off the exhaust housing.

(9) Lower Unit or Gearbox ; All motors will have a lower unit or gearbox that transmits vertical power from the motor to horizontal power to the propeller. These lower units houses the gearbox so it can be separated from the mid-section or "leg", by a few bolts. Finding a replacement water pump impeller may be a problem on some of the older motors that were sold by mail order stores.

(10) Decarb ; Chances are good if the motor has set for any length of time and you may not know anything about it, that the rings may have become stuck in the piston. This can hamper the running of the motor because of lower compression. The easiest way to help here would be to purchase a commercial de-carbonizing liquid that is ran thru the gas and / or squirted into the pistons, let set, then run it. One that is usually available at automotive parts stores is SeaFoam. This stuff softens the carbon buildup and when the motor is then ran it blows this now softened carbon out the exhaust and many times gives the motor a new lease on life.

One method of decarbing used by many is to mix a strong mixture of SeaFoam into a 1 quart to a 1/2 gallon of mixed fuel, make up a small fuel tank (as seen in the photo above) with fitting to the motor if applicable and run the motor at a medium speed let most of the fuel be consumed and shut the motor off. Pull the spark plugs, squirt more SeaFoam directly into the spark plug holes. Let the motor set for 20 minutes, then start it up. If you have carbon internally the motor will burn this loosened carbon which will SMOKE considerably.

(10) Recap ; This article is mainly geared to getting your motor running. Once it is running, there can be many other things that may be needed to be repaired or adjusted to make it function properly.

The above items are just a general outline as to what is needed. Entire books are written on the subject and for each make and individual model of engines, so it is impossible to cover all that you may encounter here. There are many tricks in taking motors apart that will not be written down. Johnson and Evinrude motors are designed by a whole different bunch of engineers than Mercury, so even thou they all propel your boat across the water, they can be very different in internal design. Some motor designs are easier to work on than others and the engineers at Mercury apparently drink a different water.

OK, so you now have it running but it will not starting when warm. Here are a few things to check out: Does the pee water (overboard water indicator) functioning OK when running, if not then it could possibly be running to hot because of a bad water pump or debris inside the cooling system. Is the fuel tank venting correctly? The ignition coils can act up after getting warm, do you have fire in both cylinders after warm up?

copyright © 2009 - 2019 LeeRoy Wisner All Rights Reserved

Back to Ramblings

Originally stated 06-03-2009, Last Updated 11-25-2019

Contact the author