|

|

Removing Stubborn Bolts & Seized Pistons From Outboards |

|

The difference between a 20 minute repair job and a 2 dayer is a seized/twisted off bolt head.

Below I will describe 4 different situations and how I overcame them. You will notice that all are different, yet similar. The process remains pretty well the same. There may be some duplication here as they are used in 3 separate articles then combined here for ease of accessibility.

Probably your worst issue in repairing these OLD motors will be seized bolts. Most of the time it is not the threads that are the issue, but it will be that the screw/bolt body below the head where it goes through what ever it is attached to will be corroded. Here no matter how much penetrating oil you apply will not help. The head may twist off, but depending on the location, you will have problems getting the part to slide off the now broken off stud.

Don't Break it

Off to Start With if Possible :

(1947 2.5hp Elgin restoration)

Here you MAY have

some choices, depending on where it is broken, and if there is part of it

protruding enough to get Vise-Grips onto etc. The other option is to just

leave it broken off and go with one less bolt IF that is all that is broken, if

more than one then you will have to decide if it will create a functional

problem. Many times the stainless bolts are stuck worse than regular steel

bolts, because of the oxidation between the two different metals. And

stainless is a lot harder to drill than mild steel bolts. It will be a white

powder.

AND I have NOT had any luck using an Easy-Out in any of these bolts that are

smaller than 3/8".

(1) If when you try to unscrew the bolt, it has resistance to where you feel it may twist off, (remember these will usually be 1/4" bolts) play it careful. Usually if you try to use penetrating oil in this case the oil will not get UNDER the bolt head. The corrosion will normally be between the bolt shaft and the metal surrounding it but not in the threaded area that it is threaded into. My solution here is to use a small angle head grinder to remove the bolt heads. Now you should be able to pry the cover plate off these now bolt studs.

Now use method #2 to remove what is still in the base material.

(2) If you have broken it off, and it is protruding enough to get ahold of it, (even a 1/4"), I would first soak the area with penetrating oil, If you do not have any, the best alternative is hydraulic brake fluid. However a machinist's formula seems to perform as good or better than any over the counter penetrating oil, is automatic transmission fluid mixed 50/50 with acetone.

Build a dam around the broken bolt if possible with modeling clay. Let it set for a few days and during this time, tap the protruding broken end with a hammer a few times. This vibration tends to break the bond and allow the oil to soak further in. Now try a Vise-Grip pliers to see if it will turn. If it does, only move it slightly, then back up, then try to loosen it again. If you do it all at once, you can break it off again, and this time flush with the housing, which complicates matters. OK, this is the easy one if you got it out. If not, then you might try to heat the aluminum up slightly with a torch in the area of the broken bolt. Don't get it overly hot as you may melt the aluminum. What this may do is about the same as tapping it with the hammer in that the aluminum will expand faster than the steel bolt and may help break any bond between the two. Do the soak and tap again. Try the Vise-Grips again. If it takes you a week, it is better than the alternative. DON'T GET IN A HURRY.

In the photos below even after the bolt heads were removed, it was a chore to even remove the head because of all the corrosion on the sides of the bolts. With more penetrating oil and a waiting process, 5 of the 8 were able to be removed. The other 3 needed to be drilled out, then the threads were Helicoiled. Partial threads survived on these 3, but since these screws held the head on, it seemed prudent to fix it right.

| Here the head bolts were corroded enough that when the 1st one broke, it was decided to set it up in a milling machine & cut the heads off the bolts | The head is now off the cylinder so that the removal of the bolts can now be easier |

|

|

|

(3) If the above failed or the broken bolt is flush with the housing, I would again use the soak and tap/heat method, but now you have to drill it out as close to the exact center of the broken bolt as possible. If it is a 1/4" bolt the hole size on the inside of the threads is about 3/16". I would use a center punch, try to locate as near as possible the center of the bolt. Remember that this small bolt the threads being a spiral, that you will see the outside of the threads, while on the other side you will be seeing the female part of the casting as looking straight down on it. Try to locate the center where there are no threads. Tap the center punch lightly. Look to ascertain if it is near where you want it. If not then place the center punch back in the original hole, angle the head end away from where you want the hole to really be. Tap it again at this angle whereby you may shift the original punched hole slightly. When satisfied that is is as close as you can get it then clamp it in a large drill press or milling machine, so you can clamp the part RIGIDLY so you can control the drilling. If you do not clamp it securely to the drilling unit, the part WILL shift AND you will drill off to the side.

DO NOT DRILL IT BY A HAND DRILL WITH NO RIGID SUPPORT. Use

a GOOD sharp drill bit with the hopes it will drill straight and not run out to the

side. You can drill it with a hand power drill motor, BUT the odds are that

you will not be able to hold it straight then the bit will wonder (TAKE MT

WORD FOR IT). Use a cutting

oil on the drill as you are drilling. If you succeed in having it centered,

the bit will go hard, until it breaks out thru the end of the bolt. You may

be able to feel the difference it at this point, as it will break into a

hollow space below the broken bolt and into a deeper threaded section of the

casting, as the threads will always be slightly deeper than the bolt.

If you did not get the drill lined up

exact or it shifted so the drill took out just part (1/4) of the threads on

one side, this should be no problem as there should be enough to still hold.

Now you can use an ice pick or cape chisel to get under one side of what is

left of the threads then work them out. And possibly use a Dremel tool with a

carbide dental burr to cut the bolt shell in enough pieces to extract them

from the threaded hole. This will free the hole enough to run a tap into it

and

clean up the threads.

(4) If the above #3 failed and the drill ran out to one side, you will have to enlarge the hole enough to install a Helicoil. This is simply a somewhat square wire tightly wound as a spring in the exact thread pitch as the desired new threads. You will need to purchase a Helicoil kit, which includes the proper drill size, oversize tap and an installation tool. Here again it may be best to use a rigid drill press or milling machine, clamp the part to ensure you get it close enough to align the new threads to the other mating surface. Here you might use a appropriate undersize end mill to clean up the butchered hole and remove what is left of the broken bolt before you use the Helicoil drill. Follow the instructions on the tool.

(5) As in #4 if you have tried to hand drill the bolt out, the drill will run to one side because you can not hold it steady. This usually will then drill out possibly 1/2 of the thickness of the bolt/screw. You can take a round punch and grind it to a taper on one side of the tip, then use the long edge to try to get under the remaining bolt that is now partially drilled. If the hole goes all the way thru you are in luck as this is easier to break up the pieces, then drive any out the bottom. If it is a blind hole, you will again try to punch the part that still has some threads on it out into the hole, loosening it. You may then have to use a Dremel grinder along with carbide dental burrs to cut this part of the bolt into small sections so it can be removed.

You now need to clean the hole, possibly run a tap the same size as the bolt threads to be sure there are no pieces left in the hole. Mix up a metal type epoxy, (JB Weld) pretty much filling the gouged out hole. Spray a silicone or smear Vaseline onto the treads of new bolts and using the part that the bolt held on to align the bolts to hold them in place and from tipping, insert the bolts doing a slight twisting motion to get the epoxy into the threads. Use the other bolts also that hold the parts together so you can tighten them. You will probably have some threads left internally to somewhat grip, but DO NOT really tighten as you do not want to strip out what is there. Let it harden to about 80%, try to slightly unscrew these bolts just enough to break any bond that may have occurred. Let it set and when cured remove the bolts, file off any excess epoxy and then reinstall.

Corroded

Bolt in Lower Unit :

(1987 9.9 hp Johnson water pump

impeller change)

This may happen when

you try to separate the upper housing from the lower unit. If

the 2 center bolts are the broken ones they are probably the least

important ones and this HP of motor may well operate without them. However here

is a method if repair other than a complete upper housing replacement.

The housing is aluminum with the bolts being stainless steel, not a good

combination to remove in the 1/4" size. So first off try NOT to

break the bolts. If a bolt does not want to unscrew without excessive

force, try another to get a feel as to what it takes to break the bolt

loose initially. Then go back to the stuck one and try again. If the

bolt moves even slightly in a tightening direction, it probably is

frozen and all you are doing is to twist the bolt itself. Not a good thing, be

careful as it may be seized and you are simply twisting the bolt.

Rap on the bolt head with a hammer, trying to jar it a bit.

Don't be mislead into thinking it is starting to unscrew as it may

just be starting to twist into. If you suspect this, try to

rap it with a hammer and retighten a bit, then again try to unscrew it.

Usually not all are seized so by trying others you should get the feel of the ones that will unscrew as compared to the other seized ones. If it does not want to unscrew, leave it and use the method below.

In the photo below, after observing many of these, I suspected the corrosion was between the lower unit hole and the bolt body itself, not in the threaded section. The bolt did not want to readily unscrew. Leave it in and proceed as below.

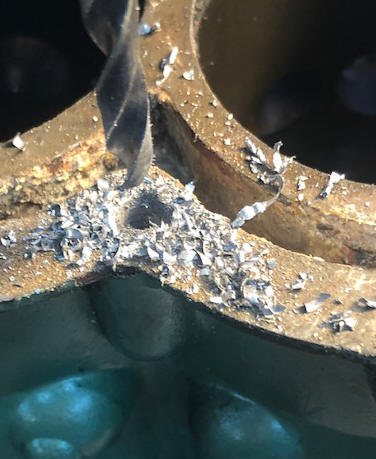

Here I use about a 3/32" drill bit, drill a hole in both of the housings where the bolt shank goes thru the lower unit AND into the upper housing where the bolt is threaded into. Drill in just until you hit the bolt body and then slightly into the threads but just enough to open a channel into the housing threads. Put some penetrating oil into these holes. Tap the aluminum with a small hammer at this location. The purpose of this is to try to get some of this penetrating oil to get into the shaft and threads. The tapping may expand the aluminum slightly plus allow some of the oil to seep into the threads. Let it set for a couple of days. Tap some more, put more oil in the holes, try to unscrew the bolt. If after about 3 tries of this, and you still don't succeed, use an Oxygen/Acetyne torch, heat the area at the threads to where the paint is burned off. Put more penetrating oil in the holes then let it cool. Try to unscrew the bolt again. If it starts, then back it up to tight, then loosen it again to just slightly more than the first try. Keep tightening/loosening a little at a time until either the bolt unscrews, or breaks off. It is EASY to think the bolt is unscrewing, but in reality it may be twisting itself into. All the more reason to stop, back it up, oil and tap, let it set for a day.

| Here you will see 2 holes drilled into both housings where penetrating oil was allowed to soak into the bolt body & threads for 5 days. Tapping the upper area with a hammer resulted in the paint being damaged, but it loosed the seized bolt |

|

|

Now it would be best IF there is any bit of a stump of the bolt protruding to soak it with a penetrating oil repeatedly for a few days. Tap on this broken bolt as you soak it. Then try to get a ViseGrip plier onto what is protruding then slowly work it back and forth. If it does not move even slightly soak and tap again. If still no movement then heat the bolt with a torch as above, while warm soak again with a penetrating oil. Note one of the best penetrating oils is common brake fluid.

As mentioned before, the drill the bolt and use an Easy-Out, usually does not work on these corroded bolts because of the size of the bolt, you can not get a large enough Easy-Out in the small bolt, which just wedges the bolt sides tighter into the threaded hole. Or you may break the Easy-Out in the bolt and that is way worse getting it out.

Many times if a motor has been left with the lower

unit in the water for extended periods of time, (like on a sailboat)

where just the bolts into the extended housing will be seized.

This is not as bad even if numerous bolts become twisted off simply

because once you have the extension off the motor it is easier to work

on repairing/removing the broken bolts.

A method I would use is to drill, Roto-Root with a Dremel Tool etc. to

remove the broken bolt. A trip to your personal dentist and twist

his arm (smoked fish may help here) for any discarded carbide dental burrs. These are small

and

fragile, but do very good when a hole is drilled into the broken bolt

where

these burrs are used to go inside the hole and cut what is left of the

bolt into 2 pieces which make then for a lot easier removal.

These oil holes can then be cleaned and an epoxy or body putty can be used to fill the holes, being sure that the threads are protected. Touch up paint is easier to do than breaking a bolt.

Another Method of Repairing a Wallowed Out Thread Hole : If the hole gets wallowed out bad enough by not having a drill press or milling machine, then you can go to Plan C, which is, OK now I have an oversize hole that needs threads and in the right location.

You will now have to tip the motor upside down or in a position where the hole is up. Make a template of the bolt pattern, (thin aluminum or heavy paper) mix up a metal type epoxy, (JB Weld) and pretty much fill the gouged out hole. Spray a silicone onto the treads of new bolts, then using the template (or existing mating part) to align the bolts, hold them in place and from tipping, insert the bolts doing a slight twisting motion to get the epoxy into the threads. Let it harden to about 80%, try to slightly unscrew these bolts just enough to break any bond that may have occurred (not the other ones that did not break). Let it set and when cured remove the bolts, file off any excess epoxy, reinstall.

Twisted Off Lower Unit Bolts : This above method was used on a 1965 5hp Evinrude when all four 1/4"exhaust housing to lower unit bolts twisted off in preparation to replace a water pump impeller. On this motor, two of the bolts broke off with about 1/4" protruding. After soaking a few days with penetrating oil and repeatedly tapping on the broken studs, one bolt unscrewed using a Vise-Grip pliers. Another twisted off close to the housing and the other two were so short to try this method.

What was also tried on these was since the thread bosses were somewhat accessible from the inside, a Dremel tool and #409 cut-off wheel was used to slit the inside of the boss down into the threads, hoping some pressure may be relieved and at the same time allowing more penetrating oil to seep into the threads. Also a heat gun was used to heat each area and allow it to cool before trying to remove what was left in the hole. Not sure that this accomplished anything, but it surely did not hurt anything.

Since this exhaust housing is so large that it could not easily be mounted in a drill press or milling machine, all the holes had to be hand drilled. Shown in the photo below, the broken bolt on bottom right has been removed. This drill ran off a bit toward the center of the housing, but enough of the threads remain to act as a guide for the greased bolt when inserted along with J B Weld. The upper left bolt has been drilled with a 1/8" drill, (slightly off center but doable). And the left lower bolt only has been center punched as near center as possible, ready for another steady hand.

The normal method here will be to now use a 3/16" drill bit that should (if centered) just, or nearly drill out the main body of the bolt, leaving most of the threads. Then using a Dremel tool and carbide dental burrs to reach inside and split what is left of the the bolt in two pieces, which can then be picked out with an ice pick or driven out the OPEN threaded hole on the upper part of this housing.

Now that you have the broken pieces out of the hole and you plan on using this epoxy method of restoring threads, you need some sort of fixture to align the bolts as close as possible to as they were originally. This could be done using the other part of the bolted on housing, or a aluminum fixture plate. The plate was chosen here because of the problem of also aligning the driveshaft into the crankshaft spline while dealing with the unhardened Epoxy wanting to run. This was also chosen because I did not want to drain all the gear oil if I removed the driveshaft. A piece of 1/16" aluminum was selected, a 1/2" hole drilled in the approximate location of where the driveshaft would be. This plate was then slid onto the gearbox with the shaft protruding out the hole. The plate was held in place and 2 holes were marked using the gearbox as a location marking guide. Once these 2 holes were drilled, the plate was placed back on and aligned with 2 bolts into the 2 holes. The other 2 holes were marked and drilled. Now I have a fixture that can be used to Epoxy new threads into 2 holes. The reason only 2 holes is so the unit can be placed so gravity will keep the Epoxy near the lower holes. When they are hardened, then do the other 2 holes tipping the unit again so gravity works for you.

Here, just inside the bolt boss are recessed lips apparently to align the water pump housing. In the epoxy (J B Weld) thread restoration, these will also be filled so they can be re-machined with the Dremel tool later.

The reason that these bolts may have seized is because of the depth of the drilled hole. All of them broke out into the outside of the housing above the flange. This could very well allow corrosion to start and it is unknown when the last time this was apart to change a water pump impeller. Upon reassembling, anti-seize will be used on the threads AND stuffed down into the open cavity above the ends of the bolt threads to help seal it off.

Or, do as I did on this unit. I used a couple of fully threaded 3" or 4" 1/4" stainless steel machine bolts, cut the threads to length to be used as studs, (just long enough to thread into the hole and protrude the length of the gearcase flange plus a nut). These turned out to be 1 1/16" for the front and 1 1/4" for the rear. These studs were epoxied into the drilled out holes and what was left of the threads, using the aluminum jig for proper alignment and let cure. This is a close fit, but still just allows the use of a 7/16" box wrench to remove the nuts.

Now the gearcase unit can be installed in place and stainless steel nuts holding it in place. But also using anti-seized on the exposed threads so little chance of corrosion will grow there. However if it does, the gearcase can be carefully removed without fear of twisting off the studs.

| Here you will see a bolt threaded into the lucky hole and progress being made on the others. Also notice a paper towel stuffed up into the housing to keep filing/drilling debris out. | Here you can see the stainless steel studs JB Welded into the housing as mentioned above |

|

|

|

There is another trick that can be used here to drill out broken bolts, however it usually does not work well with stainless steel bolts as they are a lot harder than regular steel bolts. This is to use a Left hand drill bit. These are available in sizes specific for normal bolts and are designed just for this removing broken off bolts. The theory is that when the drill starts to bite into the broken bolt in the hole (IF IT IS NOT SEIZED), since it is rotating left handed on right handed threads, it MAY unscrew the broken part out of the threaded hole.

More Twisted Off Bolts : (1980 70 hp Johnson power trim/tilt motor replacement) Shown in the left photo below are two of the four twisted off bolts in a Johnson 70 hp power trim/tilt unit. They were soaked with penetrating oil and pounded on with a hammer occasionally for a week. Then even tried to be heated with a Oxy/Acetylene torch, however 2 of these bolts were so close to the oil reservoir that not much heat could be applied without fear of damaging the interior valves & other parts. However one broken bolt was removed using a Vise Grip plies during this operation.

With these 3/8" bolts that tight, it became obvious that ay Easy Out would not do any good, and would possibly even worsen things. So on to plan "B" fro this job. This would be mount the unit on a vertical milling machine. Since it was so large a unit, even the 6" mill vise was dwarfed. So a 10" angle plate had to be clamped onto the mill's table to hold the unit as square as possible. Then some sort of clamping method had to be devised to hold the unit against the angle plate.

Once the unit was mounted securely, the tops of the extended bolts were milled off flush with the base so it would be easier to locate center because of the Vise Grips had chewed up what was protruding. A sturdy center drill was used by eye-balling to locate the drill location. Since these bolts are 3/8" and I wanted to drill out the body to as close to the inner thread size, a 5/16" drill was the right size. The bolts was made of stainless steel, which has a nasty habit of work hardening if the drill is or gets dull, ran too fast and or without lubricant/coolant, so the RPM of the mill was reduced to 240 for this operation.

A good sharp drill and lots of lubricant was used. Everything went well in drilling out the broken bolt because of the rigidity of this setup. At the very end of the bolt when the drill caught, it pushed the short un-drilled end deep into the threaded hole, but this was OK as if needed, the new bolt could be and was shortened slightly to compensate.

In the photo on the

right below one bolt has been drilled out while the other is still protruding.

| Broken bolts during removal of the unit | Drilling out the broken bolts in a milling machine |

|

|

|

Clean Out Threads : With the center of the 3 bolts drilled out, now an ice-pick was used to dig out some of the remaining threads. A Dremel tool was also used with a small round stone to remove part of the old bolt that I had not gotten the drill exactly centered on. Grinding and picking produced parts of the old bolt threads as shown in the photo below.

With the old thread pieces removed, a 3/8"x 16TPI tap was ran inside the threads to clean up any damaged areas. Also this tap was ran thru the other good threads. This drilled out hole may have become slightly enlarged since the center drill was not centered exactly, but enough of threads were retained to hole considering there were 6 total bolts holding this unit in place.

This particular unit uses (4) 3/8" x 1 1/2" and (2) 3/8" x 3" stainless steel bolts.

Before total reassembly a 3/8" drill was ran thru the clamp bracket endplates to remove any corrosion debris. During reassembly of the unit into the brackets, a anti-seize compound was applied to both the threads and shank of the new bolts.

In the photo below using the rigid milling machine for precise alignment you can see that the main bolt body was drilled/milled out and only the threads needed to be picked out of the aluminum housing. This is the desired outcome.

| Broken bolts & the dug out threads after drilling |

|

|

One precaution here that may help someone at a later date would be to before you reassemble things to run a proper size tap (1/4" X 20 TPI being the normal size for most small outboards) into each of these holes cleaning up the threads. Then when you reassemble the unit, place a dab of anti-seize compound on the threads.

Twisted Off Head Bolts :

OK. In another motor that I had to tear the

powerhead apart to be able to install a new crankshaft, in removing the head 5 of the 10 1/4" bolts twisted off. One seized in the head,

the others broke at the block. The stripped block was put in a large milling

vise on my milling machine, the center of the broken bolts were eyeballed and the table locked, using a starter drill then using a 3/16" stub drill to drill

through the seized bolt. Ideally I wanted the holes to be slightly offset.

Because then I using a Dremel Tool and a 1/8" carbide cutter, by go inside the

hole, and cutting away the thick side of this broken bolt, I could (sometimes if

I was lucky) take it out in 1/2s.

Then I cleaned the holes up with a

1/4" X 20 TPI 2 flute tap (2 flute because a 4 flute may not follow missing

threads as good). Then on the holes that were seized, I lightly greased (a light

oil will not do) the threads, then using a guesstimate amount of JB Weld in the

threadless side of the holes, then screwed these new bolts in, until they

bottomed out, forcing the epoxy out into the cavity of the missing threads. Let

the set for 6-7 hours and remove the bolts before the epoxy is totally cured,

just in case the grease did not totally stop the bolt threads from being

unremovable. Clean them up with the tap and you are ready to go.

I just hate it when there are that many.

| Here you see the center drill | Here you see the clean up drill | Here you see the finished hole |

|

|

|

Now, after all the broken threads have been removed, I either Heli-Coil the hole back to 1/4 x 20 threads, or if there is a substantial amount of threads left, I lightly grease the threads on a new bolt, smear JB Weld in the hole and screw the bolt in and bottom out in the hole, forcing a small amount of JKB Weld into places that I could not otherwise get it into. The light grease makes for a non stick bolt that can readily be removed. This then gives me a 100% thread contact.

Then the block and head

surfaces were somewhat corroded, requiring resurfacing. Here I used my

son's 4" stationary belt sander with 120 grit, which quickly cleaned them up as

seen in the LH photo below.

In the RH photo below, shown are 2 non broken head bolts of

the total 10 (5 that twisted off). Also 2 broken ones, and 2 more of

partial threads that were removed from the drilled out hole.

| Here you see the block and head after resurfacing | Here you see the 1 /4" broken head bolts |

|

|

Seized up Pistons : Numerous times you may run into a motor that is seized (the flywheel will not rotate). This could be from numerous reasons, (1) It may have sat in a damp corner of a old barn and the pistons have corroded enough that they are seized. (2) Same as number one but they were a saltwater motor that was not flushed well, -- making for a worse condition. (3) The motor was ran on fuel that did not have a proper/or no oil mix. (4) The motor was ran without being in water OR with a failed water pump, getting this water cooled motor overheated and the aluminum pistons got hot enough to gall in the cylinder walls, seizing the pistons.

Number one and two can usually with a LOT of TLC be freed up and made serviceable with some cylinder honing and may or may not require new piston rings. Number three depends on the severity of the damage, as it could have damaged the connecting rod bearings AND scored the cylinders all because of lack of oil. Number four could be a crap shoot as to being able to salvage the motor. If it is BAD, the block may have to be rebored to a oversize and new matching pistons/rings installed. Depending on the age and size of the motor would determine if the cost would be prohibitive (OR IF PARTS WOULD EVEN BE AVAILABLE).

Now, let's get into unseizing a stuck motor. Probably the best bet would be to verify just what you have. Is it really a seized piston? It could also be a bolt or coil came loose on the timing plate and is binding the flywheel. OR it could be a rusted/corroded and a seized gearbox.

Okay, you have determined that it is the pistons. Here it is best to remove the head so you can then really inspect the situation. What I do is to lay the motor on it's face so the block is UP providing a location where you can pour penetrating oil in on to of the pistons. Depending on the rotation, (piston location) possibly you could soak both (remember this is a 2 cycle and has intake and exhaust ports in the cylinder walls). The best position would be if both were part way up, with the worst one being up and the other down (Top Dead Center) on the crankshaft.

After soaking a few days, by using a wooden block, and a large hammer, pound on it (on top of the piston) trying to get the piston to move. If it moves a bit, keep it up, or alternate to the other piston, If not, then more soaking would be required. Try one piston, then the other.

If this works, try to get it where you can rotate the flywheel. If it is not that bad, you may be able to salvage it by with a piston down, and using 120 grit emery cloth and a rotating motion, remove slight rust enough to put it back together. However if it is bad, eventually you will need to remove the powerhead and totally disassemble it.

Sometimes, the only way to get the pistons loose and out, would be to split

the block away from the intake manifold side to where you can access the

bottom end (front) of the connecting rods and remove the caps, where you can

then again using wooden blocks drive the connecting rod/piston out.

This is also the method you would use to actually remove a piston.

Here, you encounter other issues like marking the connecting rods so the

caps stay with the right rod AND in proper relationship to each other.

Also if the bearings are removable, they need to be identified/marked.

In the photo below (a Johnson TN28), I knew the block was BAD, but I needed the crankshaft, so salvaging anything else would have been a plus. The pistons are so seized, the only way to get to the crankshaft was to split the block, then one connecting rod bolt was so corroded/rusted undersize that a wrench would slip off it. On this one, I had to cut the bolt head off with a Demel tool part off stone to be able to get the crankshaft out, leaving the pistons still in the block as seen below. As it turned out the crankshaft was only marginally usable, but later I did find a NOS crankshaft.

| Here both pistons are BADLY seized |

|

Once you get into it, what you find will determine your avenue of repairs. Some may be salvageable, to where a motor may be made to run again (possibly not like new, but run).

If the situation was #3 where it was ran on no oil in the fuel mix, AND was stopped in time, depending on the motor, you may need new/used connecting rods and new bearings. SOMETIMES you can salvage the crankshaft by using emery cloth to "shoeshine" the bearings and get them serviceable. And if the cylinder walls are scored, they often can be honed to become serviceable also. But you won't know until you get deep into it.

However, I had one of my own that was starving one cylinder because of a blocked reed valve. This one broke a rod and threw part of it right out the crankcase wall. On this I had the hole welded and bought a new piston, rod and bearings. It is still running as far as I know.

Copyright © 2011 - 2022 LeeRoy Wisner All Rights Reserved

Back to the Main Ramblings

Page

Originated 07-10-2011, Last updated 11-04-2022

Contact the author