|

Improving Import Band-Saw On/Off Switch Location / Light |

`

|

Improving Import Band-Saw On/Off Switch Location / Light |

We home shop wood and metal work

enthusiasts are now pretty much confined to purchasing machinery made in either

Taiwan or China. And you are pretty well limited to their modern manufacturing

shortcuts. Here, I see the desire to make parts that can be somewhat

universal, creating families of machine tools, to save money from not having to

make somewhat duplicate parts (and in this case the bases where the on-off

switch is located). BUT for me, with the on/off switch on the base, where you

have to lean over to turn it ON or OFF is a safety issue. I want the switch up

near arm level where it is easy to operate without hesitation.

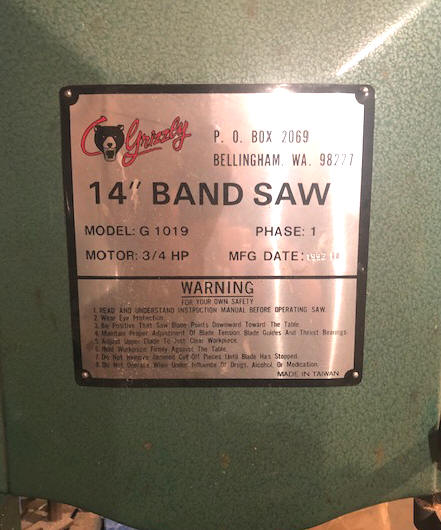

The saw I am working on here is a 3/4 HP 14" Grizzly #

G 1019. I recently traded my larger old Walker Turner to my son, who

purchased this one new in 1996.

| Here is the bandsaw I am working on. |

|

I had an experience with the same switch location on a import tool and cutter grinder a number of years ago. On this new machine, on my first power up, I had to lean over (with my head down in line with the grinder stone), and when I hit the "ON" button, before I could raise my head, the motor started AND upon acceleration, the grinding stone disintrigated, with major parts of it hitting me in the head above my only eye, breaking my safety glasses. That happened with me at the age of about 45 and caused major floaters that the optometrist explained was because at that age at that time, (and that hard a hit) that it broke loose some material inside my eye. LESSON LEARNED.

| Here we see the old switch location on the base of this bandsaw. |

|

Reposition the Switch :

My plan was to move this

existing switch up and onto the LH side of the overarm

bracket at a height more convenient to operating it.

But the existing switch box was made of plastic mounted

behind the front panel and not usable as a front mount in

the location I wanted it to be. The plan was to

use a new conduit outlet box to be used to mount the switch

into.

Basically,

what was involved was to

disconnect the power cord, pull the existing push button

switch out, code the wires and add a new wiring from the

inlet terminal block, and run these wires from the base up

to the new outlet box. The new outlet box was to be a duplex

conduit box. However on my initial measurements, the US

cover hole spacing of the box was narrower that the Taiwan

switch by about one hole, so I welded the old holes in the

"new" outlet box, and drilled/tapped to match the

Taiwan spacing.

After I got the switch off, I then discovered this new US made conduit box was considerably narrower and shallower than the original Taiwan plastic box that was mounted behind the base material. This proved to be just too small, so I had to fabricate a new metal box about 2 5/8" wide by 4 3/8" long and 2 1/2" deep. This depth gave me enough room for the wiring to not be cramped. I then welded internal lips on each outer end which were drilled and tap #8-32 holes to the spacing matching of the old Taiwan cover plate holes. A 7/8" hole was drilled in the bottom of the box for installation of a 1/2" Romex wire clamp for the wiring to be pulled through.

On

this switch, the cover contained the actual push buttons

separate but directly

in front of the actual switch buttons.

To mount this new outlet box, I

used one existing threaded hole in the overarm casting where

one of the two screws went to attach a plastic blade cover,

then a second 10-24 screw and nut behind (to keep it from

rotating) in the rear of this new box. Then drill a

5/8" hole just below the metal box on the plastic cover for the

new wiring to go out and up into

the box.

To run the wiring

from the base up to the new switch location, there also had to

be a 5/8" hole drilled in the top of the sheet metal base,

another in the outside of the casting, and a notch ground in

the cast iron above to allow wiring to be run up behind the

plastic cover and up, then out into the

new switch box.

| Here we see the newly located power switch illuminated by the light. |

|

Then a plain

sheet aluminum new cover plate was added to cover the now

existing old low switch location hole.

Add a Table Light at the Same

Time:

While

doing the above and changing the wiring, why no add a light

over this saw?

Here I had a unused old swing arm light that was collecting

dust, so I cut part of the arm off, welding it to a steel

plate and mounted it behind, but near the new switch.

This weld was so that the arm is now ridgid, but placed where the

light hood could be twisted to illuminate the saw blade

better.

For the mounting

this duplex outlet receptacle, I used the center knock out plug

in the rear of a this box and drilled a 13/16" hole in the cast iron

overarm, fastening this box and light bracket using a 1/2"

close pipe coupler and two 1/2 conduit nuts. This

provides a sturdy mount along with a conduit for the wires

to the switch duplex box. This light already had it's

own twist knob switch, so I just used a duplex outlet and

plugged the shortened cord plug into it.

For

power to this outlet, just trace down the incoming power

cord connections and run wires up to this outlet box.

Originated 11-22-2020 Last Updated 03-12-2021

Contact the Author