|

Fishing Reel Identification & Maintenance |

|

It goes without saying that there are numerous types of modern fishing reels. These can be separated into different categories and then sub-categories. Freshwater and saltwater being a starter. The main difference between freshwater and saltwater is the saltwater reels are generally larger bodied with a larger line capacity and generally more rust resistance. Within those groups will each be different types of which could include, single action, level-wind spool type, open-faced spinning and closed face spinning reels. And then there are those fishermen who collect the oldies.

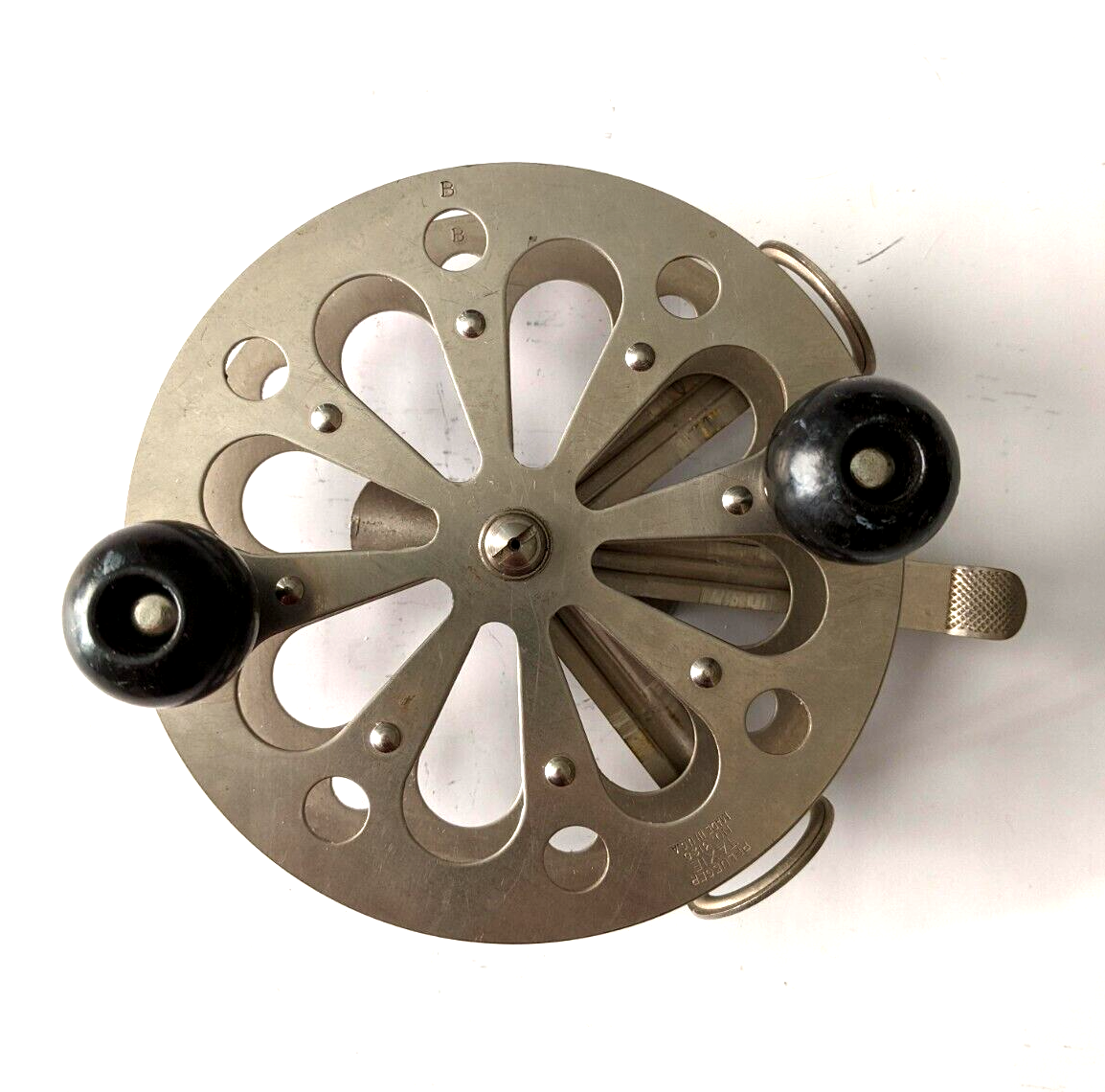

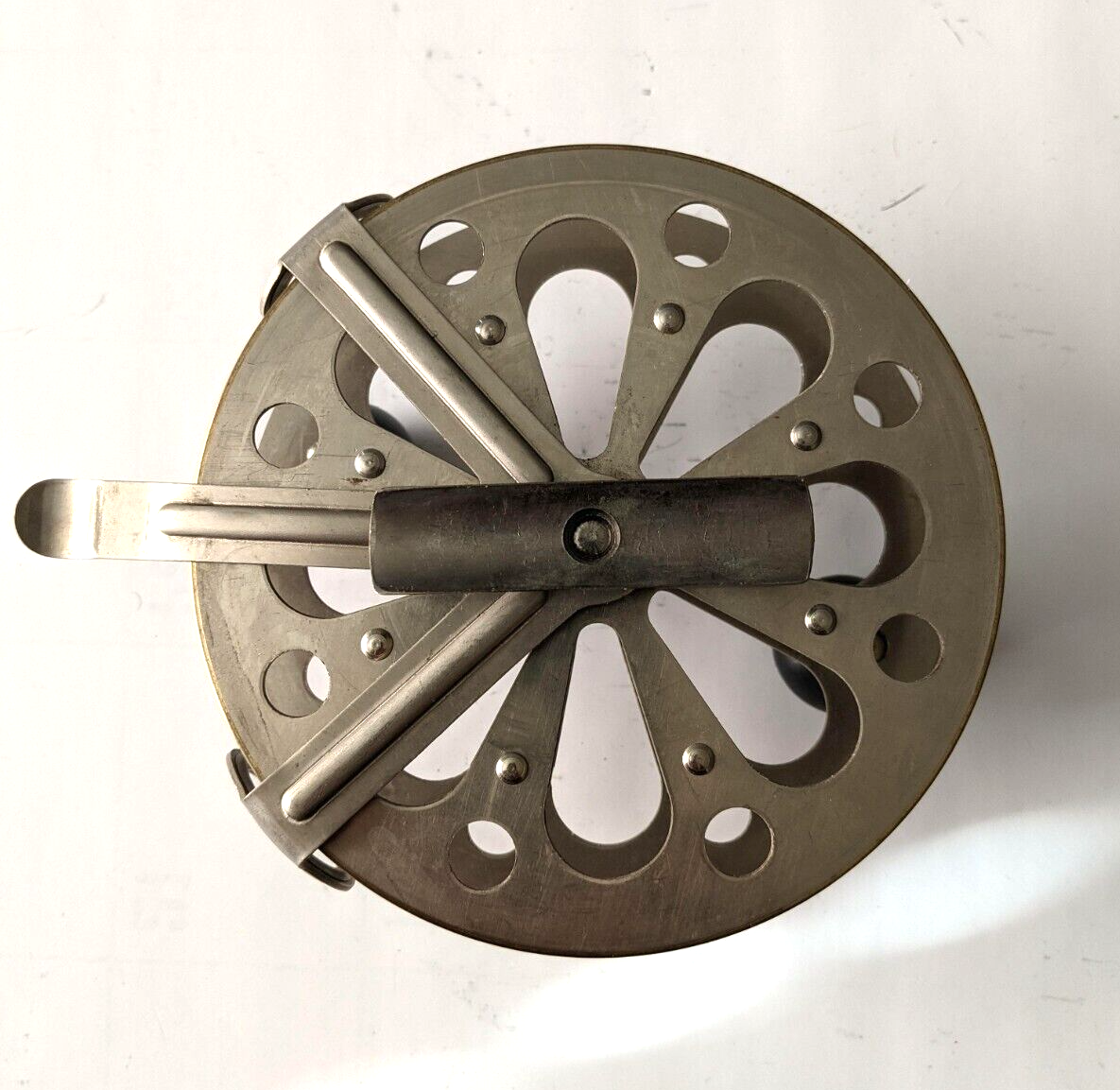

| The drag here is your thumb on the heavy leather against the spool's line | Here is another old thumber |

|

|

|

Most modern fishing reels are not only for storing line, as when used for larger fish the friction drag system is especially important. Those rotating spool type, if used for casting are normally equipped with ball bearings for smoother operations instead of just bronze bushings. Generally the more ball bearings the smoother the operation and the higher the price.

A properly set reel drag allows larger or powerful fish to be safely brought in and landed, as the drag will "slip" below the breaking point of the line if the fish makes a sudden run. This in combination with the flexibility of the rod, puts constant pressure on the fish, tiring it more quickly. As a rough general rule, the drag should nominally be set at about one-half of the line's breaking strength. This drag can be adjusted up or down as needed by the fisherperson while playing a fish, by what is called a star drag wheel or non some reels a lever activated drag. The "Star Drag", name is usually associated with the star shaped wheel located directly behind the crank handle that is used to tighten or loosen the drag.

In the early reels, the handle was directly connected to the spool, here if you wanted line to go out the handle would also turn in reverse, later a clutch disengage system was devised that could also incorporated a ratchet system allowing the spool/line automatically be connected to the drag system when fighting a large fish. This clutch/disengage system, which usually is manually activated by a lever, (or push button depending on make/model) disengages the spool allowing the line to free-spool out, as in letting the line out as in trolling or mooching, or when casting.

The photos of reels shown here is to give you a sampling, while not trying to promote one brand over another. Some are ones I purchased many years ago, like the Airex Bach Brown model 5 open faced spinning reel that I bought new in the spring of 1955 along with a 8' Betts solid fiberglass steelhead rod. I still have both, and the reel's booklet, and bag along with a small round metal grease container for the reel.

As a fisherpersons expands their horizons, they may soon learn that "One Size Fits All" does not really apply when it comes to fishing rods and reels. Other reels shown here are ones that I have picked up over the years to fill in the gaps while others happened to follow me home over time to make a friendship with naked rods I had, that needed such a relationship. I will say that I do not really have any favorite reels, some however are better than others for specific purposes. I am still trying to find the perfect reel for my type of fishing, and I do think I am getting closer, OR manufacturing technology is getting better after 75 years. I do have some that I use more than others, however I just do not have the time to spread it around and therefore some keep hanging on the wall with a forlorn look on them. And I have found that in recent times, price does not really mean quality nor longevity.

There are not many reels currently available (other than the single action reels) that have the handle connected directly to the spool, most of those that are still alive are in antique collections.

You may not realize it, but a reel that is well maintained may well increase your hooked to landed ratio of larger fish such as steelhead or salmon. If your success declines, you may try a lot of other things to increase your ratio, first thinking your hooks are bad, or your rod is not matched to the needs at hand, or possible you may even try different line, or begin to wonder if it is just you, getting older. However you may do yourself a favor and closely inspect your reel's drag washers. Most of the reels you are using will incorporate a drag system of some kind, if it gets to when when the line is being pulled out, it is not an SMOOTH even pressure or if it does so in jerks, your drag washers may need attention, or replaced, maybe just a good cleaning and re-lubricated. Or you WILL loose a nice fish (which can cause the fish pull loose or break off) because the slightly uneven pressure on the fish (depending on the location of this worn drag in relationship to the friction discs), giving this drag a slim chance of smooth operation, and if taken advantage of, that fish may be history. And while you are at it, the spool bearings may need adjustment or replaced to help prevent a casting backlash.

Disillusionment : Sometimes one begins to wonder as to is it worth the money to invest in a higher grade reel as to long term dependability. My question is just what do you expect the life expectancy of a $180 reel to be?? In my mind, I would think well over 10 years, but maybe I am being lulled into thinking that because now automobiles are being made with over 100,000 mile warranties, when years ago a car was worn out with those miles.

Just because the reel is expensive does not mean it will be possible to repair it down the road in a few years. And do not be swayed by a name brand that is so much thought of by fishermen that they do not ask a professional reel repairman for advise before purchasing one. Here I will name names.

I have had 50 year old Penn reels that seem to last forever AND parts are still available if needed. It seems that the design was outstanding and they have built newer versions around that. Another reel in this category is the Ambassadeur, however I have found one minor problem, if you use these for trolling even slightly heavy tackle (salmon), it may be impossible to push the clutch release button in unless you slightly reel in enough to relieve tension on the spool engagement dogs. Fishing reels seem to fall into the category way different than computers that need to be replaced every few years because of one or more malfunctions.

However, a salmon fisher friend took a couple of his Shimano Tekota 500LCs in for professional cleaning/repair. One was a 10 year old reel, it was returned unrepaired, he being told that some parts (the one he needed, essentially the IAR bearing) were not available anymore from the factory, and this reel was now only good for spare parts. I acquired it because I wanted to try to convert my wider 600 into a narrower 500 spool reel and could possibly use these parts to do so. In tearing it apart, I found that the main crankshaft anti-reverse bearing's needles were gunked up so badly and I could not tell if it was dried chassis grease of some kind or rust to where the needles were dry and not able to rotate (because this bearing was not designed to be readily removable from the housing). You could hear and feel them complaining when you cranked the handle. I have no idea of what led to that situation, as the other smaller outer shaft bearing was fine. Anyway, no big deal if that is all that is wrong, buy a new bearing, so I looked it up online and found that this bearing was indeed now obsolete/discontinued.

WOW, he paid near $180 for that reel and now it is scrap. The odd part that I find here, is that most bearings are not made by the manufacturer of the product it is used in, (this is so throughout any industry, even vehicles). So I would not be surprised that this bearing is still being made and used on some item, but without a manufacturers part number to cross-reference to, it would take a LOT of measuring to possibly find the right one or a usable replacement. Another thing I found during this disassembly is that one of the cone shaped drag washer springs was so collapsed that even if the bearing was available, this spring would have also need replaced. Why would a company make a spring that was not heat treated enough to withstand even the lightest treatment (like the drag being tightened during the off season)? And this owner does not use his boat - rod/reels a lot, only for a month at the Columbia River Buoy 10 salmon fishing each year.

I have the same reel only a wider version, and I have never had any issues with it (other than servicing the line counter), and I probably use mine more than he did.

FAST FORWARD -- I recently

found a bearing company that makes this bearing, BOCA Bearing. And they

have a website catering to fishing reel bearings, also giving cross-reference

numbers. This Shimano factory bearing was #TCT0488, BOCA's

equivalent # is EWC1008 and sells for $15.95. This was my guess all

along as mentioned above, as usually bearings are NOT made by the end product

manufacturer. Now possibly the reason for this factory obsolescence is that the reel housing (handle

side) uses two stainless steel pins to secure this bearing plate in place AND

OVER TIME, IF USED NEAR SALTWATER, these pins can become corroded into the

aluminum housing, making for a very good chance of breaking the housing when

trying to get the old bearing out. Is it possible that the factory is

not willing to admit to a design failure, and not wanting hassle from the

customer, so they just changed the bearing securement on later models and then

listing the old bearing as being obsolete? Or they will only sell it

(new version) as a sub-assembly with a new housing?

I suspect that it can be replaced IF a special fixture was made to really

support that housing as the pins were pushed out.

The moral of the story could be two actually. (1) Don't be swayed by a lower priced reel being junk, where you could buy one of these different cheaper model/brand that would still perform to your requirements. But how do you know about the long term issues unless you personally buy a new one (different brand) every few years and use them hard. Most of us do not have the time nor resources to do that kind of a thorough test. And I am sure that if you ask 100 different fishermen the best brand/model, you may get 80 different answers. (2) However, if you take good care of even a less expensive, BUT WELL designed reel, like cleaning and greasing preferably every year, MAYBE they would last a lot longer. Then just maybe doing your own repairs in the off time, OR TAKE TO A PROFFESSIONAL you may certainly get better and longer life out of it. It seems that the more money you spend, the more the idea is that it is a good/should be of higher quality and close to being indestructible, however the newer reels have a whole lot more internal parts to go wrong than the ones we used as kids.

So I guess you either consider taking someone else's advise, (but advise can only as good as the price you paid for it) or spend your money and hope for the best down the road. For my type of salmon fishing, line counter reels are very convenient. I have numerous ones that for one reason or the other I have/am/was not totally happy with some models. They may be fine for someone else, but not for me, one has the clicker that is very hard to put on if your hands are wet. Two other different makes, the line counter resets are in the way and not protected to where many times you will inadvertently bump this reset at the wrong time. Another one the counter display window would repeatedly fog up. Another the counter's clear plastic cover fell out and you can not just buy this small cover and glue it in yourself, but are forced into buying the whole new $30 end piece, again a Shimano Tekota. I have also found that most line-counter reels need MORE ATTENTION than the non-counter versions. I understand there are a couple of brands out there now with a digital counter, which may be worthwhile to look at, but I hear that changing the battery is similar to that of a battery operated wrist watch (not an easy thing).

You will also find in the same manufacturers, may have

different models of the same style, which may use the same parts, they only

change (add ball bearings instead of bronze bushings then add on decorative sideplates)

on the more expensive models. If you are one who trolls or sits on

anchor most of the time, you will get by just fine with the cheaper reel that

has bronze bushings in some of the non critical locations.

In repairing these older reels, don't get disheartened if the parts you

need may be obsolete. As said above, many reels are made in "families",

or numerous reels using the same parts. It may just be that the older

obsolete reel was the forerunner of a newer deluxe model and some of these

parts may interchange. Here I am referring to the Shimano Corsair

casting reel. This basic reel materialized into the modern Calcutta

model. Many screws are the same, even the spool friction cap uses

the same threads (different number) but it can be utilized if the older one is

missing.

Penn is famous for a good basic design and expanding on it for

later reels.

| Now here is a Fred Flintstone fishing rod/reel |

|

The Difference Between Cleaning & Maintenance : Cleaning could be just a light washing the reel down with WARM soapy water, (which should be done each time it is used anyway). One factory Rep. suggests that you take it into the shower with you (especially if used in salt water). The worst thing to do is use it in salt water a day or so and then put it away until winter if that is when you have time. Salt corrosion, is going to be your worst enemy and on the newer line counter reels even if you did not get it wet, but just the salt air can deposit enough on those delicate parts to make the counters malfunction.

After a good washing and inspecting the reel's normal operation, to removing a side-plate then inspecting the innards. Sometimes cleaning could result in needed repairs if problems are found. I have had reels brought to me that are 40 years old with the appearance of NEVER BEEN APART. One being a Penn 209. This was indicative of salt corroded cross bars, caked on grease, seized level wind pawl and broken drag washers. I am sure this did not all happen at once. All the above is the result of no maintenance, but a DAMNED good reel design to have survived that long being neglected and abused and still somewhat functioning. NOTE -- I am not a reel repairman, but do my own, and for a few friends. I have had no training, just look at a parts list and start, however some take a lot of head scratching to understand the engineering and reassembly. But be on the lookout for those parts that have taken flying lessons.

| Here is something you don't really want to see, in the fishing world it's called a Birds Nest | Backlash |

|

|

Reel Maintenance : One thing that has been preached to most of us since we started, is that on any drag system reel, to back off the drag when not in use. This does two things, it allows the drag spacer/washers to become relaxed, preventing the possibility of the washers becoming stuck together and it also relaxes the strain on the drag washer springs, which may give longer spring tension life and allow the drag to perform as designed the next time you use the reel. The one exception here is if you are going to wash your rod and reels off with a light spray from a garden hose, (AND NEVER FULL POWER) then before and until you have finished this process, you need to tighten the drag. What this does is help prevent any water from getting in/on the drag washers, which if left that way for an extended time, could seize the washers to the plates or allow rust to start in the main gear that the washers seat into. But after you are finished then back this star drag off for your storage.

A suggestion, do some of your initial maintenance, on the water or at least after daily usage. If you are a bait fisherperson, clean it after each usage. One well known rod/reel repairman recommends that you spray WD-40 on the reel BEFORE usage, then wipe it off, leaving a light protective film on the outer parts. Then do it again at the end of the day, again wiping of the excess. His theory is this gives some protection to parts that are hard for you to service without a total teardown. And if you happen to get any on the line, well that may just act as a scent blocker.

Primary maintenance, by this, I mean that during the season you need to do primary maintenance, at least wash it off with water (warm soapy water is a good start), especially if you are fishing in salt water right after you get off the water to prevent cancer from starting both inside and outside of the reel. Again do not spray high pressure water into the reel with force as it will also force debris inside, but just enough flow to wash it off is good. Again when doing this, it is best to set the drag tight so that any water does not get into the drag washers, however once the wash-down is complete, then you need to back off the star drag so there is no strain on the washers during storage time. Many times just washing does not really cut it as you will find out if you let the reel set for even 2 or 3 months, so it is good to use warm soapy water AND the use of a paint or tooth brush to try and remove any salt residue. This salt, (even minimal) grows like a fungus.

Do your secondary (main) reel maintenance in the off season, remove them all from the rod, check for any dirt/grit or corrosion on the reel seat and underside parts that you can not see from above or on the rod.

Doing this in the off-season is crucial because if you plan on fishing within a week or so of the time you tear it down, if you run into problems, you may well have a non functioning reel for that event. By problems, I mean that very likely, you not being totally familiar with reel construction, so during your disassembly, you will have the situation where a you will encounter a jesus part, (jesus, where did that part disappear to). And these will normally be small spring loaded parts or E-clips that have attended flying school. Or when you take the reel apart, a part that you never saw may part fall out and you did not even know it was in there to start with. Now it may take you some time to figure out what it is and where, or how it fits even if you did find it. And you have to learn how to use the manufacturers illustrated parts diagrams.

Another thing to consider is that "out of sight, out of mind" may be prevalent here. Like most of the newer reels use a plastic cover over the reel handle nut. Remove this cover, nut and the handle to be able to wash the salt residue from under it and around the handle shaft hole. This will save you a lot of grief later on. Removing this cover may also be accompanied by removal of the small retainer screw on some reels. If these small screws are not removed periodically and the threads lubricated, they could become corroded into the handle and later when you really need to take the reel apart, will have the slot stripped or even more likely the screw twist off in the handle.

Plus if the reel is not washed off and/or left unattended for some time, the chrome plating on the metal parts start to get a bad cancer on the surface. The longer you leave it the worse it gets. Soapy water helps, but to help dissolve the salt there is the product Salt Away (which is a mild Phosphoric acid) that is used by boaters to neutralize the salt from their boats or outboard motor users. Just spray this on, let it set a while and then wash it off, which does wonders.

For those freshwater anglers, contaminating a reel with river bank sand certainly does it no good. Even very fine sand or mud can get inside which chews the gears up and ruins bearings. Also if you happen to be using bait, scent, etc. residue off these can / will get onto and in the reel. When this dries, reels slow down. Most gears now days are made of nylon which can become worn over time if they are contaminated. The Swedish Ambassadeur reels still have brass cut gears however. And just about all of the major brands use brass or even stainless gears for the main drive gear. If you have a backlash, you could may even have pieces of line sneak inside. Any debris can get imbedded in these gear teeth, binding things up or at least loosing any smooth operation of the reel next time you want to use it.

Different reels will require different types of cleaning. By this I mean a competition bass fisherman's casting reels will need to be finer tuned than a halibut fisherman's reel. Kind of like comparing a Chevrolet Corvette to a Ford F350 1 ton flatbed truck. The bass fisherman's requires minimal oiling/grease because of the more precise machining of his type of reel, while the halibut fisherman only requires the line to go out and back in with the drag to function reliably.

It can be disheartening to save your money, purchase a dream boat and of course then a better towing vehicle, lay out your old favorite tackle, purchase new lures, schedule your vacation only to have your fishing reel malfunction the first day of this vacation on the biggest fish of your lifetime because of your negligence. This can be especially bad if this fish happens to be on the rod your 12 year old daughter is holding onto. Yes, you may be able to dream something up to explain to her, but how do your really explain it to yourself? Kind of reminds me of one guy who buys his hooks at the discount store AND then only when they are on sale in the off season. And he then uses his used RUSTY ones the next year. Plus, I will bet that he never heard of a hook sharpener.

Then there are certain reels that even the most competent repairman shutters when one is brought in for repairs. So if you do decide to do your own repairs, get a exploded parts list or go online and print one off. Another suggestion, if you do start to take yours apart, do it on a clean kitchen table, a clean uncluttered floor, no carpet and keep the cat away. LAY OUT EACH PART AS IT COMES OFF THE REEL on a paper towel with the side down as it comes off (inside of the reel down on the towel). BE VERY OBSERVANT. Do not disassemble the whole reel at one time, but remove the offside sideplate, do repairs to it, then move to the handle side for the drag system, then move to the levelwind. Take digital photos of it laid out. DO NOT rely on memory as to where the parts came from. Then in all probability you may have not completely examined each part as you took it off, there may be slight differences where if you flop the part over in assembly, it may not function. This also helps if the reel you are working on may have had someone inside it before, who may have replaced it incorrectly, or lost parts but did not have access to new parts, jerry rigged or so used what was on hand to get it together. You would be surprised at the number of used reels that I have encountered in this condition. Some were sold simply because the drag system needed to be cleaned and re-lubricated.

If you need to order parts, try to move your paper towels to a secure location without disturbing the laid out parts.

If you do not intend to go into deep repairs, do not tip or shake the reel when you have it partially apart, otherwise pieces may fall out with you having no idea their exact relationship with the others on reassembly. One known here is on most all of the Penns, one of the four inner sideplate screws is also the retainer/pivot for the ratchet dog, and the spring just lays in a depression beside it and is held there when the gear housing is screwed down captivating this ratchet dog.

You may initially want to fill your sink with warm soapy water and a small paint brush to remove any debris both inside and out. When it has dried, start your disassembly. If you did not get all the gunk off, then use a Que Tip dipped in rubbing alcohol. The alcohol will dissolve the grease and dry quickly leaving no little or no residue. When finished you may want to lightly lubricate some internal parts with a good grade of light oil. Some internal and external parts will need a protective covering, others like the sensitive line counters will need only a VERY LIGHT oil.

If you are not using your non spinning type reels for long distance casting then the gears may need a thicker lubricant, and if you can not find one, otherwise good old Vaseline has worked for me well over the years.

Even though WD-40 may seem a good light lubricant, it has the condition where this light residue becomes hard over time making it not desirable for internal reel repair.

| From this chart below, you can see the differences in oils normally used on reels |

|

|

You may want to Google "Shear Thinning" to understand it's meaning.

Also when you purchase any reel, keep the instruction papers and parts listings. There may also be a extra spool, a tube of grease along with a special wrench used for disassembly included in the box. Many of these original papers also include a exploded parts list. If you have acquired a used reel without these listings or have misplaced yours, here is a website that has most manufacturers parts lists. CLICK HERE This website has a very complete factory exploded parts section in a PDF file form. The files are expandable in size so us blind guys can read the part numbers and they MAY have the nomenclature also listed. However I found a couple of my OLD reels not listed here. Or CLICK HERE for a link to another site. Or another https://www.reelschematic.com/

I originally started to try to post exploded parts drawings and parts listing in this article, but have since found the above websites that have these, I have since deleted the ones I had on here. Plus I do like to use the factory nomenclature when possible, and without a factory list, this would limit me to only select newer reels. This was originally planned to be a guide to do your own, somewhat yearly cleaning and re-oiling article. Somewhere along the trail, the fog set in and things kind of got more complicated than anticipated in that when disassembling some of these newer reels, it got to where I was not as comfortable as I would have liked and I was in it beyond the point of just a cleaning. Therefore, you may find a few here, not showing a complete disassemble on some of the sub-assemblies that would normally not need to be torn completely apart anyway.

Some brands of reels (usually cheap spinning reels) may not have much of a longevity if the design was not real good or they did not sell well and were discontinued rather quickly, or the importer changed brands or the manufacturer went out of business. Other manufacturers have for years, and still will sell to major retailers under that company's own brand names, so if you do some research, look closely you may discover the true manufacturer for spare parts saving you the hassle of going thru a retail store's not so fishing gear educated parts department person. There may be some slight cosmetic differences, but usually the internal parts are the same and many times even share the same part numbers with the manufacturer's.

Therefore (in my mind at least) it is best to purchase a reel from a well known manufacturer who may still have parts on hand after 20 years or so. Fishing reels seem to NOT be like computer monitors that get thrown away if the color starts fading or lines across the screen. Reels seem to have a nostalgia very similar to a firearm, that they will live forever because it was one dad or granddad used. But cheap copies are just that, and may, or may not function reliably even when new or especially over time, or a few years down the road, then no one can remember who made them or even distributed them, much less know where parts may be available from. And you will find that what level of functioning is acceptable to one person is not to another.

A suggestion if I may, after you go thru a reel and do, or have maintenance done on it, keep a record as to the date this was performed. Also keep a record as to when you spooled it with new line with the line size / make. Use a felt marking pen or a piece of masking tape, write the brand and line weight on the under side of the reel seat. And if you swap ends on the line after a few years, record that also. If you have more than one of the same make and model of reel, engrave on the bottom of the reel seat a #1, #2 etc.

As a rule of thumb, for the reels that use a Teflon type or carbon fiber discs in the drag system do not use oil or grease on them, if they do, it is only a fingerprint of drag grease. However, for the earlier ones made from a leather, cork/asbestos you may want to lightly grease, then wipe it off, just leaving a fingerprint smudge of grease. Go by what the manufacturer suggests, IF you can find this info.

Under normal conditions, one very knowledgeable repair person says to do not over lubricate the the level wind shaft / pawl of freshwater casting reels. Now what is not known to many, is that the newer high speed bass casting type narrow spooled reels, the levelwind disconnects when casting, so that may not be as important on these. However he does recommend packing this area with a light non hardening grease like Vaseline if the reel is to be used in a harsh saltwater type environment. His reasoning is also probably that these reels are not used for casting where distance is a factor, but merely for dropping the lure overboard and letting the line out as in mooching or downrigger trolling. The other reason is this grease will help block out the salt water. Personally I still have a pint of STP oil treatment that I use and put only 1/2 a drop on each side of the worm shaft.

If you have a friend (?) that brings you his reel that is totally disassembled and in a paper bag, do you help him out or just bid him farewell? For one, you can be pretty sure that not all of the parts will be in the bag. Chances are good that it is a model that you have never seen before. And even with the help of the online schematics (which many times are woefully lacking in clarity), I will guarantee that you will find parts that you can not totally identify or that you may have put in backwards, so you have to go back, then reassemble it numerous times before you get it together right. Boy would it help to have a live sample to look at here. And then if your buddy drops a spare part in just to derail you, when you find out that he has been laughing at you, you had better consider doubling any price you were considering charging him. Sure, he will say he was testing your ability, why not just let him have all the fun NEXT time.

On one occasion when this happened to me on a Ambassadeur 4600 CB where the owner made me a gift of it. OK, it only took me about 4 hours to figure out the final reassembly and then another hour to track down where one left over washer had to go. Then he even put a spare part off something that was not even off a reel in the paper bag containing these reel parts to confuse me. He had quit fishing but was aware that if he sent it in to a repair shop to be reassembled that the cost would probably be equal or more than he could get out of it on his close-out yard sale table.

There are many repair shops that do reel maintenance and most of these, if in business for any length of time have to be good at what they do to stay in business. They do provide a valuable service to the fishermen/women. The price they charge varies depending on size and version, but the usual cost is about $25 each for labor for the regular reels with slightly more for the complicated ones, with replacement parts prices above that. Is this worthwhile? You will have to decide yourself depending on the reel and YOUR mechanical abilities. For those of you who require more info or want to learn more of how to do your own repairs there is a book out there Fishing Reel Care & Maintenance 101. This business also sells reel schematics on DVDs for repairing them.

In cleaning most fishing reels the tools required are a toothbrush, Que tip, rubbing alcohol, light oil (like 3 in 1) along with a grease like Vaseline plus Shimano grease or LubriMatic boat trailer axle grease. Of course a screwdriver of the right size and a small Crescent wrench, OR look in the original box and you will find a combo tool to remove the handle. When you finish your repair, it is advisable to wipe the reel down with a light oil, then pretty well wipe it all off. Some will use WD-40, but be sure to wipe it off as leaving it on a hard residue will form. I like to use the firearm maker, Remington's Rem-Oil, which is Teflon based. Another item I have been using lately is Bo-Shield, available at West Marine.

I suggest that if you use your

gear anywhere close to saltwater (like an estuary), that SOON after your season ends, that you

tear the reels down. Even if you just remove the spool and allow the

side-plates to dry out would be a benefit. Salt air, if left in/on any

reel is not good for it if let set for a any length of time. And at tear

down time smear Vaseline as shown in the photo below to help seal water out of

the drag washers or gears.

| If a reel is used in saltwater, it is a good idea to use Vaseline on the shaft boss to help seal saltwater out of of the shaft bearings and drag washer area as indicated by the red arrow. |

|

|

Keep Fresh Line on

Your Reels :

You should consider inspecting your mainline often. This is not to say to change it

every season, however under certain conditions (especially guides), this may be appropriate, or

even oftener.

Usually you can visually inspect at least the last 5 or 6 feet for nicks or

abrasions.

Sometimes it works best to also feel that section, as your fingers can/will pick up

small imperfections that you may not be able to see. When doing a lot of

fishing, depending on whether it is river or ocean fishing, I may cut off a

few feet of mainline every day, just to be sure what I am relying on to bring

in that trophy, is on good sound line.

You may want to change line for many reasons, or flop ends

to extend the life of usable line. Do not throw away the old spools the

line came on, but

use them to spool the old line back onto, then transfer that to another empty

spool. From there, you can re-spool back onto the original, or even a

different reel with the used end now on the bottom of the reel spool giving

you new unused line at your terminal end.

You can make a reel spooler

by using some 3/8" All-Thread, nuts and washers, a homemade spool adapter, washers and

a electric drill motor.

| Here a homemade reel spooler is in use |

|

|

Non-Level Wind Reels :

In the early days before the level wind

was invented, the line just laid anywhere it wanted on the reel as you cranked

it in, sometimes piling up in one location on the spool. The problem was

that if it built up too much, then it would slip off the mound, and more line

would be added on top, which could create an issue later when you were letting

the line out or casting. Many fishermen during the cranking in got

pretty proficient in guiding this line across the spool with their fingers as

they reeled in..

Level Wind Reels : These are often times called bait-casting reels when made in the freshwater series. Their larger cousins are designed more for saltwater usage. They have a traveling line guide in the front of the reel that moves from side to side laying the line evenly across the spool that is driven by a pawl that rides in spiral slots cut in a shaft when the crank handle is rotated. They may have a "star drag" spool braking system between the handle and the spool that allows the fisherman to place a adjustment on the line tension that can be pulled out like by a large fish. There is a clutch release lever that disengages the spool from the handle / drag system so that there is very little drag when casting. There also can be a anti reverse system so that if a fish is on, you do not have to keep your hand on the crank handle to control it. There is also usually a clicker on one side that when put on, makes a noise if the line is being pulled out, or in for that matter.

Some of the true freshwater bait casters will have 2, up to 5 opposing small pith weights that are mounted on a small cross shaft connected to one side of the spool. These act like centrifugal balancers that are supposed to slide outward when the spool is rotating fast, putting very slight tension on a inner ring inside of the spool, to govern the speed of the spool when casting so that it does not over rev, which can create a backlash or "birds nest" in the line on the spool if the spool is traveling faster than the line can go out. This is a mechanical method of trying to replace the educated thumb on the side of the spool. Not all thumbs can be taught this delicate technique.

The trout / steelhead reels will usually come apart by removing 3 or 4 sideplate screws. Some have a readily removable sideplate where you could even change spools with other weight line without disturbing any settings or loosing parts. The better casting reels will have small precise ball bearings on the spool spindles and level wind shafts. The one drawback of level wind reels is that if the level wind pawl becomes stuck and will not pivot to change directions, it will strip the pawl off, or even ruin the shaft. The shaft that this traveling pawl / guide fits over has spiral grooves cut into the shaft, RH and LH overlapping. The line guide is driven by a pawl that is loosely fitted in the guide so it can slightly rotate following the grove in the shaft. The ends of the grooves are timed so that when the pawl reaches one end, it hesitates in the groove, then engages the other groove, reversing and making a return trip. A problem here is usually caused the pawl becoming stuck to where it can not rotate enough to make the return trip, or by over greasing the shaft with a a heavy grease that hardens over time, or debris getting collected in the spiral slots in the shaft.

And the modern small high speed casting reels now have a distinct following in the bass fishing fraternity. These are a different breed of engineering and sometimes there is a fine line between a genius design engineer and being a full blown fruitcake. Let me tell you these are DIFFERENT. You old time fishermen can have a problem learning to use one of these for it's intended purpose. However if your need is just a neat small star drag Kokanee reel, these could work well (as long as you don't get carried away with it's other functions).

The one thing that can help considerably when servicing a level wind reel is to remove the level wind pawl FIRST. If the reel has been setting for a while with no maintenance being done, AND IF the pawl is stuck in it's cap, even if you crank the handle you run a good chance of damaging either the pawl AND/OR the level wind shaft itself. If you remove the pawl first, then in your other disassembly, if it is stuck, you can remove and clean things up, preventing any damage at this time.

In 1972 Ė Penn introduced the

Leveline Casting Reel series that uses a patented rotating spiral shaft that did

not slow the line down when casting as compared to the other conventional

level wind reels. There is a requirement that the

reel be at least 32" from the first rod line guide for the level wind feature to

work properly. This unique line guide works on a internal cammed

eccentric activated arm that works into a anti-reversing ratchet that the line

spiral guide is attached to. So the line guide actually moves in minute

segments, ratcheting /rotating the spiral cut shaft with the line laying

across a top flat. This spiral cut shaft is cut 180 degrees from one side to the

other, so when the line comes to the end of one side, when the shaft rotates

more the line will lay on the taper to lay the line back across. Since

it uses a ratchet system, IF the line does not track exact, you can manually

rotate the guide shaft to where you want it to catch up. Some of the older surf casters that have not moved up the

the spinning type reels, prefer these reels because of no extra drag of a

conventional level wind. You can also get an aluminum spool for it. It's

part # 29L-200, which is the same spool as the Penn 155 and 200, that will

allow you to make it more controllable on long casting.

| old Abu Ambassadeur 5000A | obsolete Shimano Bantam 100 |

|

|

|

| Penn # 9 | Penn 350M Leveline |

|

|

|

| Penn GTI 310 | Shimano TR 100 G |

|

|

|

If you are taking a level wind reel apart for repairs, I will guarantee that when it comes time to reassemble it that you will not have the level wind cage or guide realigned with the timing of the line when it came to you. To correct this, observe the direction of the guide moving across the spool by pulling line out. Now loosen the level wind pawl nut allowing the pawl to drop down and disengage the worm shaft. Pull more line off until you mate the line's position going out off the spool with where the guide is. Tip the reel over and tighten the pawl cap, (you might have to slightly move the guide a bit to allow the pawl to engage the shaft grove). Check if it is close, if not then loosen the cap and move the guide a bit. If you got it off to where the guide goes one way and the line was going the other, loosen the cap letting the pawl to drop down, then remove the pawl, replacing it but rotated slightly to align with the other "returning" groove, or just pull more line out until you coincide and time the two.

Inside a Level Wind Reel : (Project #1) Again it is recommended that you acquire a exploded view of your reel or print off a computer page if you intends to tear it apart, however even if you do, have your digital camera ready and do not spare the clear close-up shots as you disassemble it.

Shown below is a disassembled Ambassadeur 5000A. There is a large family of these reels, with the 4000 series being the smaller capacity by simply being narrower. This 5000 series being the medium width spool (with a 2 7/16"overall reel width). The 6000 series was a wider higher capacity spool (with a 2 3/4" overall reel width). There are also the 7000 to 10,000 series which are larger saltwater versions. I am not going to get into giving a history or where each model or numbers really fit in the scheme of things as even my trying to do internet searches, it appears I would have to purchase a book or two and then that is beyond where I really need to go here.

If the model number was say a 5500, that indicates it has high speed (5.3-1) gears. A left hand high speed 5000 series would have been 5501. Suffix letters would have indicated changes from the original version, like say the 5500-C3. The 3 in this case, designated how many ball bearings were in the reel. There is also a C4 version and a CB, with the latter having a thumb clutch/brake. None of these reels have a clicker mounted on the outer end of the sideplate. There is a internal clicker of sorts, but it is really a spring held ratchet dog sliding over the anti-reverse gear. However there are some later versions have a rotating clicker on the off handle side of the case. All of the Ambassadeur reels will be serial numbered on the bottom side of the reel seat.

The older (pre C) reels had

a boxier LH sideplate and could be painted different colors. Initially

the colors could have designated different models/versions, some even being limited

editions. These reels had knurled bearing caps on each sideplate which could be adjusted for spool sideplay or friction to help in

casting.

The newer C3 reels abandoned the boxier LH sideplate and utilize a rounded sideplate while eliminating that outer bearing adjustment. The clicker (if there is one) is mounted on the outer sideplate's rim and rotates on this rim from that position. Some of the newer versions have the clicker while others do not. And if you are handy with tools, you could purchase the parts to convert your reel to a clicker version (if compatible).

First, there are 3 knurled nut heads protruding from the RH side (under the crank handle), remove these, (they will not come all the way out even when they are loose as they are captivated inside the housing). From there you can pull this sideplate/handle/drag off along with the spool which will lift out of the main housing as seen in the LH photo below. This would be the initial disassembly where you can inspect parts and make a decision to proceed farther.

To remove the RH

sidplate you need to remove the handle that is screwed onto the main gear

shaft by a nut on the end. This nut is further secured by a locking

plate and a lock screw. There is

a small C-clip on the end of the shaft, remove it. Unscrew the star

drag wheel, under it is a wafer washer that has to come off.

Remove the handle outward. Take a

look at the shape of it and replace it with the dished part inward.

The RH cover has 2 small screws basically under the handle, remove them and

you can then lift off the outer RH sideplate cover, exposing the complete main

shaft, drag washers, disengage lever and springs. As seen in the middle

photo below, you can now lift off the drag washers, inspect, clean, or

replace them. When you remove any of the drag system, lay them out on

a paper exactly the way you took them off so your reassembly will be right. Some

spacers may stick to a nylon spacer/bushing, recognize this and lay them out

in relationship to how they came off. Inside of this will be a fiber

drag washer which presses against the back brass plate surface.

A note here, if that C clip on the end of the shaft exercised it's

flying previous lesions, a small fishing split ring can be used in it's

place.

It is best to not remove any of the other levers, springs or gear unless they really need to be.

Slide the spacers and the large toothed like steel thrust washer off the handle spindle shaft. Behind this toothed thrust washer will be another but larger fiber drag washer. Remove it and inspect both drag washers, clean them of any oil/grease. The gear will usually be made of steel and IF the previous fisherperson may have gotten the reel good and wet or even dunked, without properly tearing it apart and drying things out, the gear drag washer wear surfaces will become rusted. This will not be conducive to a smooth drag, and it may not function well at all. IF so, then the gear drag surfaces will need to have the rust scraped off, wire wheeled and even polished. Even the large toothed like steel thrust washer may need to be polished.

These drag washers can be used dry or by applying a slight amount of Cals Universal Reel and Star Drag grease www.cals2speed.com , then wiping any excess off , only leaving a just a finger smearing of grease on the washers.

At this point, you can see inside at the gears inside the LH sideplate. To disassemble this, you will now need to unscrew the level wind pawl screwed on cover and the pawl itself. Now if you remove the 3 small screws from that sideplate you can get the cover off, remove the shaft retainer, then slide the gear, shaft and shaft cover out from the main frame as seen in the RH photo below. Inspect and clean any debris in the gear teeth and the level wind shaft. When oiling use a good light oil of which many are on the market, I like to use the Break Free that I use on my firearms. Just a drop of oil on the shafts is enough.

In reassembling this, the level wind cover has a plastic bearing on the LH side with a notch that fits into the cut-out of the main frame. Slide this cover in part way, then slide the traveling guide over the cover, slide the shaft in all the way and secure it with the retainer on the side of the main frame. Now you can insert the pawl in the guide and aligned in to a slot on the shaft, then install the retainer nut holding the pawl in. Be sure that the pawl is not bottomed out and putting strain on the shaft. It has to be close, but loose enough so it will rotate at the ends.

Some of these reels will have bronze bushings for the spool shaft while others (the more expensive will have ball bearings. There are knurled bearing caps on each side of this reel. The RH one also has a thin copper end shaft bearing at the far in side with a piece of felt that acts as a constant oiler to that bearing so it should be lightly oiled. When reinstalling it, it needs to be tightened until it bottoms out. The cap on the LH side has the same copper and felt, but it also has a indent on one side that can be aligned with numbers from 0 to 9 on a rotatable plate on the outside of the housing and under the cap. This cap and numbers is for end shaft clearance adjustments. Setting this cap too tight will result in shorter casts, while setting it looser will give you excess side movement. On the inner part of the threads that this cap screws onto is a small O-Ring. This O-Ring is the right size so that when the cap is screwed on, the O-Ring puts tension on the inside threads of the cap so that it remains where it was set.

In the center photo, you can see the small shaft going crosswise of the main shaft with the 2 pith balls on each end. Many repair stations will not replace these pith balls as for most fishermen they will never be missed unless you are very experienced fisherperson.

On these old reels the shaft bearings are just bronze bushings, if you would like a smoother casting reel, just replace these bushings with the proper ball bearings.

This information and breakdown is basically the same for all of the Abu Garcia Ambassadeur reels, with slight exceptions depending on the model.

For a link to another Ambassadeur

step by step repair illustrated article

CLICK HERE. Or this one

CLICK HERE.

|

Ambassadeur

5000A with the 3 main shown with the sub-assemblies |

Ambassadeur 5000A with the RH sideplate showing the gears & drag parts | Ambassadeur 5000A with the LH sideplate apart |

|

|

|

|

Inside a Level Wind Reel : (Project #2) Here we will be looking at a Penn #9 which is a smallest of that family of level wind economy reels made by Penn. This is rather simple in comparison to some of the others. No fancy ball bearings, just bronze bushings, so it is not designed for casting, but just a nice little reel where a slightly larger quantity of line is needed over the regular freshwater casting reel size. The Penn #109 is the same reel only but is a slightly wider spool sharing the same size and line capacity of the #209. The #309 was a slightly larger diameter reel with a higher capacity, but many of the parts, their locations and procedure is basically the same for all the four models. The #109 differed from the 209 in that it had direct drive capability by activating a anti-reverse lever, (where when the spool rotated so did the crank handle) along with having a spool disengage clutch.

In disassembly there is nothing secret about this one, unscrew the 4 sideplate screws, pull the RH sideplate off first, then pull the crank / drag shaft out to get the drag washers out. Next would be remove the LH sideplate from the base in the same manner.

One thing that I found on the #209 shown below, is that the main gear was made of steel and over time had rusted on the inner side that puts tension on the single inner drag washer. The only way I could clean it up true was to use a piece of window glass and valve grinding compound, where by lapping the roughness off and then polishing it in a lathe using fine emery cloth I was able to restore it's smoothness. The #9 used a brass gear, so no rust would be present.

To reassemble the drag system with the hard fiber washer on the shaft 1st, then the gear with the recess for the rest of the washers pointing out. Now one of the .700" dia. drag washers which appear to be a thin fiber center with a course fiberglass type fabric impregnated with a Teflon coating. This is followed by a steel flat washer, then another drag washer followed by a flat steel washer that has opposing ears on it. Next is another drag washer and another flat steel washer then a concave steel spring washer. This is all placed into the RH sideplate. Penn drag washers are designed for no lubrication to be used on them.

If you have not disturbed the clutch system, fine. If you have, then on reassembly, the 2 coil springs go into their respective holes in the sideplate followed by the pinion gear bridge, the pinion gear and then the clutch plate on top.

Tip #1 for this reel. (method #1) Rotate the main shaft plate so that the radiused side is up. There is a anti-reverse dog that goes into the sideplate that pivots on the rear lower screw. Behind it is a small flat slightly Vee shaped brass spring. To get these into position, you will need to have the shaft plate as mentioned above, place the screw with fewer threads all the way to the head up thru it's hole, using tweezers drop the dog over this protruding screw. Again with tweezers place the spring behind the dog and also behind the small brass peg protruding from the sideplate. Rotate the shaft plate to where it is in position and moves into it's recess on the sideplate. Now you can screw the shaft plate to the sideplate.

(Method #2) In the photo below is the assembly of as Penn #209, which is just a slightly larger reel than the Model #9 and of the dog spring, which in this case is a small coil spring instead of the Model #9 Vee type. Here it may be helpful to employ the use of some Vaseline to hold the this spring in position. And use one of the 4 shaft/gear housing plate screws, (one that is threaded all the way, as the actual pivot screw is only threaded on the end) but screw it into the inside of the plate and slip the dog pivot hole onto this slightly protruding screw to retain it in position. Now place some Vaseline on the dog and spring. Once you get the gear plate almost in place, use a small punch to push the outer end of the coil spring in, letting it drop into the spring recess. You now can press the plate into place, install the 2 of the other screws, remove the assembly screw and finish the screw installation.

| Here Vaseline was placed to hold the spring in place on a Penn #209 while the gear housing will be flopped over & installed |

|

|

Now you can slide the drag spacer into the sideplate shaft hole, thread the star drag wheel onto the main shaft and attach the crank handle.

Place the stainless steel sideplate covers in position on the sideplates, aligning the holes. Screw the base plate to the LH sideplate using the shorter screws, attach the cross bars with the medium length screws leaving the larger one with the slot for the level wind guide slightly loose for alignment later. Reassemble the level wind unit, pawl & retainer screw. Slide it into position into the LH sideplate aligning the shaft's 2 flat sides into it's mating gear.

Tip #2 for this reel. Rotate the level wind guide forward to allow you to position the level wind cover in place with it's 2 small pegs into the 2 small holes in the steel inner plate rings. Once the cover is in position you can tighten the sideplate screws. Slide the spool into the LH sideplate letting the shaft gear mesh with the white Nylon gear in the sideplate.

Now you are ready to slide the RH sideplate onto the spool shaft and the level wind shaft end. Screw this sideplate on using the medium length screws. Install the LH shaft tension screw and adjust the side play out of the spool.

Check the spool for free spool when the clutch lever is deployed, then check the drag. If everything is OK, you are in fine shape , OTHERWISE do it again. One thing to look at here is if the handle and spool turn hard, it may not be there that the problem lies. It could be that you have not gotten the level wind pawl in right with the pawl cap putting pressure on the pawl at the wrong location on the shaft.

For a internet link to a illustrated article on Penn reel repair CLICK HERE.

| Penn #9 disassembled |

|

|

Inside a Level Wind Reel : (Project #3) Here we will be looking into a Shimano TR 200. The early reels like this one (purchased in 1993) were named Trition 200-G. Later the name was changed just to TR 200. This reel's little brother, the TR 100 is the same size body but with a narrower spool equating to lesser line capacity.

This reel is apparently graphite body / side frame which is precisely molded. It uses basically the same design as most of these types of reels, EXCEPT everything on the RH side is mounted on the body's outside end of the main body instead of on the INSIDE of the sideplate. This makes for a lot easier assembly.

I did not take the main drag shaft out of the body, (which is held in by a E-clip which is covered by the side of the spool when assembled). One washer not shown in this photo is a spacer between the drag gear and the body as a bearing. Nor did I disassemble the level wind unit as it's construction is the same as all the others other than using a E clip to retain the shaft in the LH sideplate.

On reassembly, with the drag shaft in place as shown, install the .935" dia. drag washer which has the large center hole 1st. Next is the flat stainless steel spacer, followed by a regular small hole drag washer. Now another spacer, but this one has ears on the outsides. Place these ears inward. Now another drag washer again followed by a flat steel washer. Next comes a coned disc spring washer (#TGT0020) with the dome facing out. Another coned spring washer but with the dome facing in, followed by another spring washer cone out then the last dome washer with cone facing in.

It is now time to install the RH sideplate. You may have to slightly jiggle the clutch lever to get it to enter the notch on the clutch plate attached to the body. Insert and tighten the 2 short screws under the handle, then the 4 longer screws holding the outer of the sideplate to the body.

Now a small steel washer and the mainshaft ball bearing can be inserted into the shaft / bearing hole of the sideplate, followed by another small steel washer. Next screw on the drag wheel. After that comes the crank handle, it's retainer nut and cover with it's screw.

Install the level wind if you had removed it. Slide the level wind upper guide tube in the body being sure to insert the end that has the 2 alignment ears first so they engage the blind hole and notches in the RH side keeping it from rotating. Install the pawl along with it's retainer cap. Note that most of these reels come with a plastic guide pawl cap. However a metal replacement is available for a price of $2.00. My recommendation is that you replace the fragile plastic cap with the metal one as this is the one weak part of this reel. There is supposed to be a SMALL metal spacer between the pawl and the cap which ensures the pawl engages the worm properly.

Be sure that the small brass spacer is on the spool's shaft then slide the spool unit into the body and engage the drive flats into the mating slots of the pinion gear.

Now add the LH sideplate and it's screws. Thread the shaft end-thrust cap on then adjust it for sideplay. I like to just be able to feel a very slight spool horizontal movement.

Check your work by working the clutch lever and adjusting the drag.

Since this drag is very sensitive, if you experience where at a light drag setting, the drag wheel backing off because of the motion of a hookset to where you have no resistance and if the line plays out if a fish is still on, (or gone because you missed him), there is one remedy. Place (1) 7/16" OD x 1/4" ID x 3/32" & (1) 3/8" OD x 1/4" ID x 1/16" thick Nylon O-Rings in the star drag wheel's outer recess. There is a recess there, but no where in the parts diagram does it show anything to go in the recess. Place the thicker O-ring (7/16" x 1/4" ID) in first and you will have to push it into the recess after the star wheel is tightened down, then add the 1/16" O-ring as a filler between the 7/16" and the inside of the handle. This adds just enough slight tension on the wheel from the shaft threads when set at a low drag setting to not allow it to back off. These O-rings can usually be located at a well stocked hardware store in the plumbing section. Another option would be to use a Okuma Magda Pro #06140001 wafer washer between the wheel and the handle. This washer has a smaller diameter hole than the Shimano, but the same flats dimension. You will just have to open up the diameter a bit with a needle file.

This reel is probably one of the easiest to reassemble of all the level winds that I encountered in this doing this article.

| Shimano TR 200 showing RH side of body | Shimano TR 200 disassembled |

|

|

|

In my experience, this coned disc

spring washer, (#TGT0020) which 4 are used here is defective and

does not have enough spring tension to give reliable pressure on the drag

washers. This washer appears to not have enough heat treatment and after

some constant pressure, collapses. I understand how to heat

treat regular steel, but not stainless steel. So my redneck solution is

to make a upsetting fixture, by drilling a 9/16" hole deep enough in a block

of steel so the drill did not go all the way through. Next drill out the

center just larger than the center hole of the washer (.312"). Now

make a punch out of 1/2" rod, that had a center diameter of .287" or just

large enough for the washer to slip over and relieved enough to allow the

washer to be reformed.

Leave your drill press or milling machine

positioned where you drilled the holes, place the 1/2" punch in the chuck.

Place the washer (cone down) in the hole and pull the handle forcing the

center of the coned washer against the bottom of the partly drilled 9/16"

hole. It does not take much force to change the overall thickness from

.035" to .075".

The problem here is that now you can't get all 4

washers in (not enough room under the handle). So eliminate one washer,

but be sure that the last one on is with the cone inward so that the outer

larger part puts pressure on the outer bearing race. Otherwise it will

bear on the inner race and may partly disable the bearing's usefulness.

Also with this wider stack, you will probably have to only use one drag washer

spring #TGT0021. i have seen these reels use two or only one of these

spacer washers, so maybe depends on the factory assembler?

I have found that this makes this reel more compatible to what drag

settings you may have become accustomed to on other reels.

| Here is my upsetting tool for modifying the coned drag spring washer |

|

Inside a Level Wind Reel : (Project

#4)

Here we will be

concentrating on a Penn GTi 310, with notes on the GTi 320. This is like many of a family of reels, where the

GTi 310 is the smallest line capacity with a outside diameter of 2.925, the

GTi 320 the next size up with a outside diameter of 3.140". Both of these reels utilized a round body

with the overall width being the same for each. The GTi 330 is

a

larger diameter round body 3.680" diameter and .225" wider. The GTi 340 the uses the same

width spool with the body is tear drop shaped, moving the level wind forward

giving more room for line. The last two

models being more suitable for salt

water usage because of the larger line capacity. The GTi 340 also has

shoulder harness eyes built into the top of the sideplates.

These reels have a precise injection molded graphite body with stainless steel sheet metal side caps. The level wind carriage's upper line guide loops over a crossbar instead of the earlier models that fits into a slot in the crossbar. They have a endplay tension knob bearing against the spool's RH shaft to control excess side play, this knurled knob is located on the RH side above and behind the crank handle.

All of these utilize the disengage clutch lever that places the spool into freespool, however these reel do not automatically re-engage the clutch when you crank the handle. The difference in the GTi 310 other than a smaller diameter spool is that it has a separate free spool button on the bottom of the RH sideplate under the crank handle. When it is forward, or OFF position the reel disengages the anti reverse dog and functions like all others, but with the button pulled to the rear in ON position the reel acts as direct drive whereby the handle rotates backwards when the line is going out. The drag system still functions with this in ON. Some moochers prefer this saying it puts them in more direct contact with the lure/fish. This 310 utilized both the direct drive along with the spool out clutch, giving the fisherman the best of both worlds if they so desired. This reel was brought about after Penn dropped the 109 model which had this same style of direct drive capability.

Tip #1 for this reel. I have found it best to install the level line unit first (minus the pawl), then the LH sideplate. Before installing the level wind shaft, smear some Vaseline into the grooves. Slide the cover in from the RH side, but before it is all the way thru slip the line guide carriage onto the cover, then push both all the way into the LH sideplate. Now insert the line guide post #58 into & thru the RH sideplate, with the carriage in position so the upper hook of the carriage uprights is retained by this post.

When you install the pawl, don't put any Vaseline on it or in the cup because if it gets contaminated or gets cold the pawl may not pivot on a return pass. This can lead to it seizing up and stripping the shaft. Manually rotate the level wind gear as you try to tighten the pawl screw so that it goes into the groove easily. When you think you get it in, rotate the wheel again to ensure it has engaged. When reinstalling the the level wind shaft end nylon locking nut do not over tighten it or you will put so much pressure on the shaft that you will bind it to the point it will not rotate.

Install the spool into the LH sideplate.

Tip #2 for this reel. Reinstall the free spool lever. If you removed the spring activating this plate and lever, install it BEFORE you tighten the lever completely down otherwise you will not be able to insert the spring into it's front retainer hole in the cam.

Place pinion yoke with the clutch engage notches toward the inside of the reel. Insert the 2 coil springs into the recess's in the sideplate behind the eccentric jack plate. Slide the yoke ears under the plate with the "ears" of the yoke pointing up. Now place the pinion gear into the yoke's recess, with the narrow side of the gears pointing outward, which will also have the clutch ears on the shaft showing.

Tip #3 for this reel. There are 4 saddle screws. Two will not have threads all the way to the head. These 2 screws go in the lower holes & inside the plate springs. But first you will need to retain the dog which is under slight spring tension. Use one of the screws that is fully threaded, insert this into the threaded eccentric jack hole where the coil spring screw it in just far enough to hold the dog in place. Hold the plate in place as you insert the screws that are not threaded all the way. Remove the first screw and thread both of the others into the RH sideplate. Then thread the other full thread screws in the eccentric jack other 2 holes.

You might rub the smaller dia. fiber washer that is behind the main gear with a fingerprint of Vaseline ever so slightly, just a fingerprint will do . Then the main gear goes onto the shaft. Assemble the drag washers and steel washers on the main shaft in the same sequence you took them off. Note - some metal washers have the hole shaped to lock it onto the shaft, while other washers have ears the engage the gear's inner recesses. Slide the metal spacer onto the shaft, then the wafer washer. Now install the stainless metal sideplate over the RH graphite sideplate. Next comes the metal spacer on the shaft, then the handle and it's retainer screws.

Other GTi 320 Differences. There are some differences in the 320, and 330 in that the clutch lever is steel instead of graphite, the handle retainer screw is a larger size head and there is no removable LH sideplate.

On the early 320 models this LH sideplate frame ring is only held in place by one screw situated on the rear of the plate. The front of this ring has a partial 25 cent size 1/2 circle made into the ring, this circle has a short projection tab that goes into a mating recess of the sideplate. Just push the ring forwards to disengage this tab. This allows you to get to the level wind outer gear.

The 320 mainshaft is a larger diameter and therefore the drag washers are larger 1.095" diameter.

These reels are probably the other of the easiest to reassemble of all the level winds that I encountered in this doing this article.

| Penn GTi 310 disassembled |

|

|

Small High Speed Bass Type Reels : These reels are a totally different breed. They usually have a minimum of 5 ball bearings in the design translating for smoother spool rotation. They also usually have some sort of internal breaking system, (maybe even 2 systems) plus a spool tension knob to compensate for this free wheeling spool to keep it from over-revving and bird-nesting the line when casting. One thing is that if you are used to the regular level-wind reels, is that these level-winds disengage on the line outgo (or casting mode) possibly to help remove that resistance and give more casting distance. They then re-engage when the crank handle is operated when reeling in. OK, you ask what about the line tracking on the next retrieve? The spools are so narrow that it seems to be of little consequences.

The high speed can relate to a crank ratio of over 6 to 1, meaning the spool revolves 6 times for one crank of the handle (double the retrieve of the older reels). And these all will have a "pot belly" on the crank handle sideplate underneath to accommodate the extra large gear used to generate this high speed retrieve ratio.

They all have a thumb disengage, but MAY not have a thumb brake, where you may have to thumb the spool to keep it from unspooling prior to casting. Some with the thumb disengage is also a thumb brake if you push it far enough.

They do not hold a lot of line, usually from about 100 to 140 yards of 12# mono. They are also lightweight, usually being made of graphite for the frame, with many plastic outer parts, and Nylon and Brass gears.

Instead of being made with a ratchet anti-reverse, they are made using a anti-reversing roller bearing, which eliminates some internal parts, but at the same time this then also has no provision for a clicker for you trollers who may want to use it on a Kokanee rod.

Some of these reels will have some sort of quick access to the brake system and/or changing spools. This is usually by rotating part of the sideplate which is opposite the crank handle, which allows it to then be readily removed. To do this, some require loosening one thumbscrew, while others just by rotating this whole tight fitting sideplate. The older models that have screws on that side do not have this feature. And technology has changed so fast on these small models that, even on well known brands, replacement parts may not be available if more than a few years old.

Tip for this reel. It is advised here that you DO NOT even consider tearing one of these apart, (especially just to see how it is made) other than to remove the sideplate and spool, if so equiped. Consider this, IF IT IS SMALL AND COMPLICATED, THEN THERE WILL BE A LOT OF SMALL PARTS INSIDE THAT HAVE TO BE REASSEMBLED PRECISLEY, that you may not have seen before they fell out. How many of you would consider trying to repair your own wrist watch?

I did purchase one of these used off e-Bay for a great price of $18.95 plus $3.45 shipping that was advertised as "Parts Only". As I had suspected, it had been torn apart by someone who was unfamiliar with even a simple fishing reel. And to back up my estimation, he advertised it's problems in non-fishing reel related terms. Upon getting into it, I found one spring that was laying inside as apparently he could not figure where it went. The drag washers were lubricated way more than required. The drag friction springs were in wrong, and the star drag wheel washer was bent so bad that it had no tension on the wheel at a minimal setting. One internal part had been filed on, WHY IS ANYONES GUESS ??? And he said the line winding eye (his words for level-wind) would disconnect at times (yes, it was designed to do that as mentioned above). I can truthfully say that this was an eye opener to me as I had never been inside one of these before, so it took a lot of assembly/reassembly before I finally figured it out without a parts manual because I could not identify the exact model to look it up online.

I bought another off e-Bay for $14.99 for parts to repair one I bought at a gunshow, that needed a better star drag wheel, where factory parts were unavailable.

In the photo below is shown a Okuma Calera left hand version on the left, and on the right, the right hand Ambassadeur Black Max mentioned above. Both of these are low end Chinese reels retailing in the $50 to $75 range. However do not be swayed by the label on the Ambassadeur that is printed "Swedish Engineered", but it is actually made in China. You may now find some of the se costing upwards to $300.

| Here are the small High Speed bass type reels in both right & left hand versions |

|

|

o Adjusting These High Speed Reels : In the old days of the Ambassadeurs shown above in this article, used two small sliding pith balls on a shaft that were supposed to put a slight braking action on the inside of one side of the reel spool to help eliminate backlashes. This may have helped some, but not a lot, and the fisherman needed to learn to educate their thumb against the spool sides to control the spool's speed, (especially at the end of the cast). Many of us old geezers that worked with our hands all of our life, have so thick of skin that this thumb braking was next to impossible, and we just gave up with all the backlashes and went to spinning outfits.

With the advent of modern bass fishing, the reel manufacturers began to awake. Smaller and higher speed reels came into being along with a way better centrifugal breaking system became standard. Most of these newer systems now use a magnetic type braking system against the spool's side. These reels were a game changer. And until you try one that has been adjusted for the lure being used, you will not believe what is possible. With the spools being narrower along with the level-wind disengages during casting, eliminating that extra drag and longer casts. You say what about the level-wind not matching up with where it left off. This does not seem to be a problem, probably because of the narrow spool. They do not have a lot of line capacity, but 100 yards of 12# mono is plenty for this type of fishing, therefore the narrow spool seems to function quite well.

There will usually be two

adjustment knobs, one (a small knurled knob) on the side that the reel handle

is on. This knob adjusts the endplay on the spool. It needs to be

set so the spool does not have a lot of endplay, but at the same time minimal

friction. The other adjustment will usually be a larger and less

pronounced knob on the opposite side of the reel handle. This will usually

have some reference numbers on the outer edge. Between one or the

other, OR BOTH, of these adjustments you can fine tune the reel for the lure

being used.

The most important thing in setting up these reels, is to properly adjust

the setting of this casting brake. These need to be set for each

different weight of lure you will be using at that time. To set this cast

control devise, tie on your lure and reel it to the tip of your rod.

Tighten the knob on the opposite side of the handle until it's pointer is

midway between the numbers.

Tighten the handle side knob as tight as it will easily go.

Now hold the rod straight out or in a slightly upward position, push the disengage lever. The lure will probably not fall, now slowly turn the reel handle side knob counter clockwise until the lure starts to fall. Let the lure hit the ground and watch the spool. The spool should not spin more than one revolution after the lure hitís the ground. If it spins more than one revolution, tighten the cast control knob and repeat the procedure. If the spool does not spin after the lure hitís the ground, the cast control could be set slightly too tight. Loosen the knob and repeat the procedure. If you do it only from the handle side, your knob movement is very critical, so it may be best to get it close with the handle side knob and then fine tune it with the cast control knob, that is why you needed to set it initially in the center of it's range.

Between these two knobs, you should get the braking adjustment close. NOTE each different weight lure, you may have to fine-tuned the reel.

Now, DO NOT cast as if you are mad at the rod, but try to flip it, more of a wrist motion, otherwise you have induced way more motion where the magnets can not overcome the spool speed. Each cast needs to be performed in as near the same effort otherwise you will still get backlashes.

Level Wind Line Counter Reels : These have come on the market in the last few years. Some are good, while others just haven't made the grade yet in my book, but newer improved ones are showing up every year. However do not look only at price when it comes to dependability.

The line counter is usually a mechanical gear driven

unit that is normally run off the level wind shaft. It uses the same method as

if you manually counted the number of times the level wind guide goes across