Brands of

Outboard Motors

|

Restoring the

Clinton / Eska Brands of Outboard Motors |

Here, I will lump these two motors together on the same article as they are very similar, early on it is known that Eska bought and used Clinton midsection and lower units. AND then in1980 Eska bought Clinton the outboard divison.

The Clinton Outboard has its

roots in Clinton, Michigan. Clinton Machine Company had been manufacturing gears

for tank turrets during WW II. After the war, owner Don Thomas saw a need

and decided to manufacture a line of small gasoline engine.

His company and sales grew rapidly. Toward the end of 1946, the company employed over 1000 employees. And, by 1949 with soaring sales, they had out-grown the plant in Michigan. In 1950 Don Thomas purchased a vacant factory in Maquoketa, Iowa.

Clinton in 1952 introduced its own line of chainsaws for use in logging,

cutting firewood, land clearing, agriculture, along with utility companies and

landscaping.

An estimated

two-thirds of Clinton’s 2 and 4 cycle engines went into the power mower market.

In 1958 Clinton was given the title of “The World’s Largest Small Engine

Producer”.

The Outboard Industry was

changing in the early 60's and Clinton needed capital to modernize their plant. Mr. Thomas was unable to raise the capital required and sold the company to "The Charnay Group of New York". With the new management team in

place, Clinton Engines floundered for awhile with very little improvement.

In 1966, "Clinton Engines" ran

out of money and filed for bankruptcy. The bankruptcy court approve sale of

Clinton Engines to a Mr. Martin Hoffinger of "Lomart Company". He down

scaled the Clinton operation and reopened in 1967.

They continued to

manufacturing small engines. By 1980 the chain saw and outboard divisions

were sold off and liquidated. The only portion of Clinton that remained

was the Clinton Engines Parts Department.

Clinton was

the first in the industry to:

o

Mass produce vertical-shaft engines

for rotary lawn mowers

o

Introduce an automotive-type oil

pump in a 4-cycle engine and the “dry-type” automotive air filter

o

Use shell-molded engines

o

Use a cast-iron liner, cast as an

integral part of the cylinder block, in lightweight aluminum engines

The Eska Outboard motor was manufactured in Dubuque, Iowa. They sold its first outboard in 1960. They took a single cylinder air cooled engine made by Tecumseh and attached it to a Clinton lower unit. Later they made their own lower units. These were about as simple as could be. They made them in sized from 3 HP and later up to 15 HP, with the 3 and 5 HP probably being the most popular. They continued basically unchanged until 1973 when Eska introduced a water cooled two cylinder 9.9 and 15 HP motor.

Some were sold under the Eska name however most were under numerous

private brands. Most

all large Department Stores, Hardware Stores and some Auto Parts

Stores sold these outboards at one time or another. These Power

Heads were all Air Cooled, except the 9.9 through 15 horsepower Twin

Cylinders. Most all of the small Eska outboards had water cooled exhaust

columns using “ram tubes” just aft of the propellers (small engines),

or rubber impeller pumps an the larger engines.

Many Eska outboards used common ignition and carburetor vendors

(lawn mowers etc.) for

that period. Therefore, many tune-up parts remained available long

after the model’s obsolescence. However, hard core parts for these

outboards are getting more difficult to find as time goes on.

In 1980 Eska, by then a subsidiary of Talley Industries of Mesa, Arizona, purchased the Clinton outboard motor product line from the Clinton Engines Corp. The purchase was to consolidate area manufacturers to maintain a strong hold on the market which had dropped due to the lagging economy.

Eska Outboard Motors went out of production in 1986. Engines

continued being marketed with the 1986 model numbers until stocks

were exhausted in 1987.

Design ;

Initially the

design was SIMPLE, just mount a lawnmower motor on top of a outboard motor

lower section. Here the early motors did not care about esthetics.

Later cowlings were added to where their motors actually looked like what people

had gotten used to seeing from the other major manufacturers. These

coverings could have been sheet metal, or even later plastic.

Most

Fuel tanks were usually integral, built around the upper part of the motor, and holding a gallon or less of fuel. On the later (and usually larger motors), a fuel pump was added and a remote tank connected to the motor using a quick release coupler. And since these were small motors, the remote tanks were usually about 3 gallon and modified form existing round gas cans. On some larger (specifically a late 5 and 7.5hp) there was a valve and coupler installed so that the owner could use either the integral fuel tank (of less than a 1/2 a gallon) OR the remote fuel tanks. The quick couplers appear to be the common commercial type being used by Chrysler on their marine engines.

Most of these motors were designed to be used in freshwater, therefore it seems that the aluminum lower parts were not prime coated before painting, and if used in saltwater, AND NOT washed off afterwards would accumulate salt corrosion as seen in the photo below.

Clinton 5hp ; 1970 (?) Clinton Apache model J9-1100A which has a aluminum suit case type cowling.

| Here a Clinton Apache motor |

|

Statistics For These Motors :

These are

Bore diameter

2.120"

Stroke 1.620"

Displacement

5.76 CI

Starter manual

recoil rope type

Bearings,

Ball & Needle roller bearings throughout

Carburetor -

High speed jet - Fixed

Idle jet -

Starting point 1 turn out

Fuel capacity - remote

3

gallon tank

Fuel mix - Per gallon of gas, SAE-30 Oil

1/3 pt. 50-1 ratio

Point gap - .020"

Spark plug -

NGK BR6HS,

or Champion

J12J, gap .030"

Flywheel key - 1/8" X

5/16 X 7/8"

Flywheel nut -

7/16" X 20 NF, -- 11/16"

wrench size

Water Pump - Rubber impeller for

cooling midsection

Gearbox - None / 360 reverse

Gearbox oil

- Hypoid 80 /90

Gear

Ratio - 15-26 ?

Prop -

7 1/2"

X ??? 2 blade LH

Prop nut -

1/2" X 16 NC -- 13/16" wrench

?

Prop Nut cotter pin - 3/32" X 1 1/4"

Weight 36#

Eska 5hp ; 1979 model 14106B. In the photo below is a typical late restored Eska motor.

Statistics For These Motors :

These are

Bore diameter

2.090"

Stroke 1.750"

Displacement 6 CI

Starter manual

recoil rope type

Bearings, Ball & Needle roller bearings throughout

Carburetor - Tecumseh ? .812 - Outlet dia. with built in fuel pump

High speed jet - Fixed

Idle jet -

Starting point 1 turn out

Fuel capacity - remote

3

gallon tank, or 1.2 liter integral

Fuel mix - Per gallon of gas, SAE-30 Oil

1/3 pt. 50-1 ratio

Point gap - .020"

Spark plug -

NGK BR6HS,

or Champion

J12J, gap .030"

Flywheel key - 1/8" X

5/16 X 7/8"

Flywheel nut -

7/16" X 20 NF, -- 11/16"

wrench size

Water Pump - Rubber impeller for

cooling midsection

Gearbox - None / 360 reverse

Gearbox oil

- Hypoid 80 /90

Gear

Ratio - 15-26 ?

Prop -

7 3/8"

X 3 ?

2 blade LH

Prop nut -

1/2" X 16 NC -- 3/4" wrench

Prop Nut cotter

pin - 3/32" X 1 3/8"

Shear Pin -

5/23" X 1 1/16" stainless steel

Weight 35#

These motors use a Tecumseh powerhead and use a magnet type magneto ignition.

There are a couple things that you should know about this motor.

First, it has a water pump with a rubber impeller in the lower unit even though it is basically an air-cooled motor. Water is pumped to the bottom of the powerhead to help reduce heat and condense gases. If the water pump is not cooling properly, you could seize up the powerhead.

Second, if the motor has a separate gas tank with hose, be careful when pumping the primer bulb. The carburetor has a orange fuel pump bladder in the back of the carburetor that will split if you pump the bulb too hard. Once the bladder splits, the motor will not continue running. You can pump it up, it will start, and then it will die. If it has the gravity fed gas tank on top of the motor, you still must have a good fuel pump bladder in the carburetor so it will operate properly.

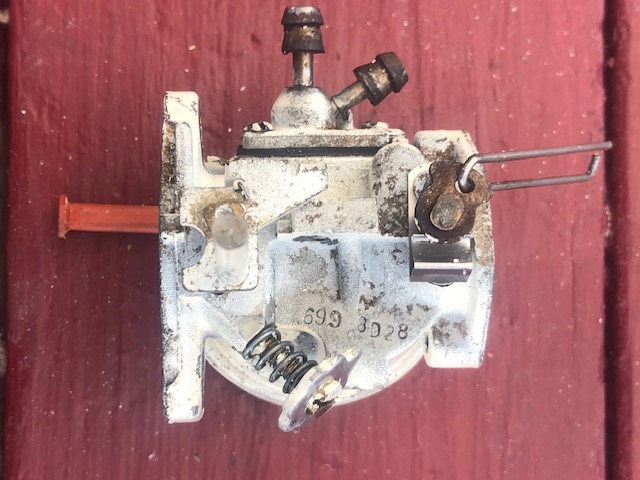

In the RH photo below, is shown the new bladder (in the wrong position) along with the old one laying just outside for a side view.

|

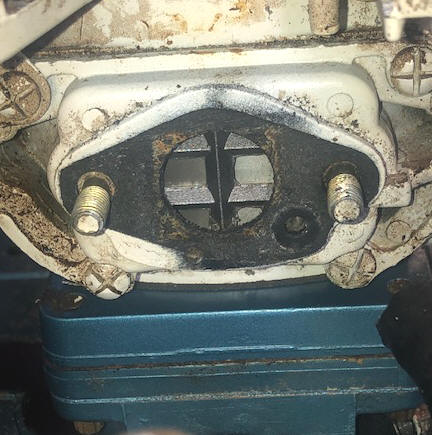

Here you see the intake manifold with the reed valves behind. And the bladder suction hole on the RH bottom |

Here you see the rear of the carb with the red bladder fuel pump. Here the bladder is in wrong, it needs to be at a 45 degree angle with the top pointing inward |

|

|

This

carb is apparently a Tecumseh design. As seen in the

photo below there are two fuel line fittings. The rear comes from the

integral tank which has a shut off valve before it goes to this fitting.

The front fitting comes from a remote quick disconnect fitting on the front

cowling.

The main-jet is fixed. The idle jet knob is seen below

angled downward. This is an unique arrangement, in that the approx. 1/2

dia. lightly knobbed wheel has one protrusion as a stop against a protrusion on

the out carb body. The unusual arrangement here is the head of the needle

is a small hex head. The knob has a mating detent to accommodate

about 1/2 the width of this head, locking it in place once it is tightened

against the coil spring that encompasses the needle screw. To get this

idle needle set, you will have to simultaneously depress the knob enough as you

rotate the needle to disengage the needle's hex head tightening it until you

just lightly touch bottom. Now you have a starting point of backing it out

to the prescribed idle starting position. Which

I cannot find listed anywhere, so my guess would be 1 turn out.

In the photo

below it is hard to see the high speed throttle arm as you are here looking

directly down on top of it. The choke lever is on the right, showing

the wire connector to the pull knob.

Not seen here, behind the fuel pump body, is a shallow round

hole of just over 1/4"dia. in the carb body that a VERY FINE wire screen fits

into. This fuel pump is held in place by 2 small screws, and all the

components are indexed by rectangular protrusions on both ends, one being longer

than the other.

| Here you see the dual fuel line inlet on the fuel pump body that houses the valves, not the bladder in line with where it resides in the carb body | |

|

This carb is held onto the manifold by (2) 1/4" flanged nuts, but not the standard 7/16" size wrench, by 3/8". Things are so close only a SHORT handled wrench works, and then it may have to be modified.

Eska (J.C. Penny) 7.5hp ; 1979 JC Penny (Eska) model #0903-A

Statistics For These Motors :

These are

Bore diameter

2.430"

Stroke 1.750"

Displacement

8.17 CI

Starter manual

recoil rope type

Bearings,

Ball & Needle roller bearings throughout

Carburetor - Tecumseh ? .812 - Outlet dia. with built in fuel pump

High speed jet - Fixed

Idle jet -

Starting point 1 turn out

Fuel capacity - remote

6

gallon tank, or integral

Fuel mix - Per gallon of gas, SAE-30 Oil

1/3 pt. 50-1 ratio

Point gap - .020"

Spark plug -

NGK BR6HS,

or Champion

J12J, gap.030"

Flywheel key - 1/8" X

5/16 X 7/8"

Flywheel nut -

7/16" X 20 NF, -- 11/16"

wrench size

Water Pump - Rubber impeller for cooling midsection

Gearbox - Neutral-forward / 360 reverse

Gearbox oil

- Hypoid 80 /90

Gear

Ratio - 15-26 ?

Prop -

7 "

X ??? 3 blade LH

Prop nut -

1/2" X 16 NC -- 13/16" wrench

?

Prop Nut cotter pin - 3/32" X 1

1/4"

Shear Pin -

Weight 40#

One bad thing on this motor, it is a single cylinder 7 1/2 hp motor, that requires a great amount of effort to pull that starter rope fast enough to start it.

| Here you see a badly salt corroded lower section |

|

Cooling ;

The design of most of

these motors was using an air cooled motor, which in turn made for a hot exhaust

housing, therefore discoloring or burning the paint. To solve this issue,

both Clinton and Eska used a water pump designed to just cool the housing.

This impeller was a bit different than most that you will see, being smaller in

diameter and thicker, designed to fit inside a skinnier lower part of the

exhaust housing just above the gearbox. Normal impellers are larger

diameter as they need to pump enough water to cool the engine. Here it

only needs to cool the aluminum exhaust housing, so volume needs are different.

Propeller ; The props may be one item that can be hard to find a replacement for. Yes, there was a blue Gajillion of these motors made, but no real reference (that I can find) as to what prop fits what. So you may just be at the mercy of trying to find a used one off the proper sized motor. And some of those selling it may not have any idea.

| Here a late Eska, JC Penny 7.5hp redneck modification | |

|

These motors (at least a 1979 7.5 hp) recommends a 50-1 fuel /oil ratio. The larger motors that also use a remote fuel tank use what appears to be a Chrysler quick coupler.

This Page Under Construction

Back to the Main Ramblings Page

Copyright © 2022 -2023 LeeRoy Wisner All Rights Reserved

Originated 04-18-2022, Last updated

10-04-2023

to contact the author click here