|

|

Maintaining

Johnson / Evinrude 1980 - 1983 , (Information & Observations) |

|

, Evinrude, OMC, outboard motor, outboard motor repair, 9.9, 15 hp, date/year of manufacture, water pump, carburetor, long shaft, 15 hp conversion, sailmaster

|

|

Maintaining

Johnson / Evinrude 1980 - 1983 , (Information & Observations) |

|

The photo above on the left is a 1980 4.5hp

One thing that I want to convey here is that I write only on motors that I have

actually worked on, and over a period of MANY years, consisting of many THOUSANDS

of hours, and then more in maintaining/updating these articles. They are

motor specific, HOWEVER if you are having a diagnosis issue, my Trouble Shooting

article covers MANY more aspects that may help you diagnose your issue.

CLICK

HERE for access to that

article.

OMC (Johnson and Evinrude) utilized a lot of parts interchange between models and HP of closely associated motors in those days as it was simple to create "Families" of near HP size motors using the same parts.

General Observances : These 4.5hp 2 cylinder 2 cycle motors were made from 1980-1983 (in the US) which utilized the newer (at that time) exhaust housing/lower unit for that small size motor, and the twist throttle unit used the cable type with a kill button on the throttle end as found on the later models. This motor utilized the to later become standard 3 years later on the 6 and 8hp exhaust housings, transom clamp assembly, shifting and gearbox assembly. It still used a shear pin at the rear of the prop.

This motor seems to be a morphodite in that for the HP, it is

a heavy motor. Maybe it was a short lived design to come up with a

motor requirement of less than 5hp for some lakes? It surely is not one of

Evinrude's Lightwins.

If you look up a parts list, the 4.5 and 7.5 hp motors of these

years are lumped together, however these 4.5hp motors used a totally different powerhead. I am not really sure why both are listed as this family,

unless it was because they both used the same midsection/lower unit, as the 7.5hp

powerhead is not anywhere near the 4.5hp. However the lower unit of the 4.5 is almost identical to the later 1984-1991 6 and 8hp

but it uses a different prop.

The first major difference of the US model was the 4.5hp Johnson that i worked on used an integral plastic type fuel tank under the upper cowling basically using gravity feed. The second main difference in that the carburetor has a built-in fuel shut off valve on the outer inlet side of the carburetor, activated by rotating the choke knob. And the third main difference is the starter. I can not find a thermostat for this 4.5hp, which may not be bad as most of these small motors are run a a low trolling speed anyway. One more thing, the spark plugs are tucked up under the fuel tank so far, that there is no possible way to access them UNLESS you use a spark plug wrench.

Essentially, again even though these two motors (the 4.5 and the 7.5 hp) of these years are listed as a family, they are indeed individuals because of a different powerhead and fuel system. As mentioned above, the exhaust housing, lower unit (using a gear ratio of13.29 for both) and the transom clamps are all the same. Maybe that is why the factory lumps them together on the service manual. Even the upper motor cowling is the same, with the exception of the internal fuel tank filler hole on the 4.5hp.

In the parts manual, it also lists the 4.5 hp as having a external tank, so maybe that was an option??? Later I now have acquired a 1984 4.5hp Evinrude made in Canada (E5RHCRV) which has the external tank and cowling of a 7.5hp, only a smaller powerhead. And this is not even listed in the US parts lists, however it seems to be pretty much the same as the US 1983 4.5 hp motors.

| Here you see the rear view of the Johnson with the only HP designation | Here you see the rear view of the Evinrude |

|

|

|

Year of Manufacture : This is important in any repair, for obvious reasons. Prior to 1979, Johnson used the last 2 digits of the year in the model number. Here is a LINK to help you determine any of the Johnsons. And here is the LINK for the Evinrudes. For those of you readers outside of the United States, here is another LINK that may better help with your motors.

After 1979, OMC's manufacturing year code, which included Evinrude, is the word "INTRODUCES", with each letter equating to a number ie: I=1, N=2, T=3, R=4, etc. as illustrated below. As before, the last 3 letters are what you are looking for. Then in this case, disregard the last one, as it pertains only to a model revision that only on specific cases may be reverent to a marine repairman if problems arise. A code of J5RCSS would equate to Johnson, 5hp, with no other letter, meaning a 15" shaft, CS = 1980, and the S could be a model revision, so this motor would probably be made in the very last part of the year. For more detailed information on worldwide production, CLICK HERE

|

DATE CODE |

I |

N |

T |

R |

O |

D |

U |

C |

E |

S |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

0 |

Using this code system, if the motor was sold as an Evinrude, then the first letter would have been an E instead of the J for Johnson. Then you can encounter motors made in or for other countries, which will have some added letters as mentioned later in this article.

There should be the model and serial number on riveted on 1” X 2” aluminum ID plate on the LH side of the transom mount bracket (looking forward). Sometimes this ID plate can get removed. If this happens, you can still usually tell which motor it is by looking at the 25 cent size soft plug in the upper rear RH side of the block. The model and year are stamped in this soft plug also but probably only up to 1979. You may find that the plug numbers do not match any of the codes, as the factory changed things as time went on.

Exploded Parts Lists : For a internet link to a marine parts seller CLICK HERE that has exploded views as shown below in this article. From this business, you can identify the numbered parts ad purchase parts online from them.

Internal Engine Parts :

This engine has a bore and stroke of 1.5625" x

1.375" with a ring width of.0625" and a displacement of 5.28 Cubic Inches. Both the center main bearing and the connecting rod bearings

are non-caged needle bearings riding in a stainless steel liner. These

bearings are not interchangeable as the center main bearing is larger than the

rod bearings.

Flywheel / Electronics : To get to the electronic ignition which are under the flywheel, you will need to pull the flywheel off the tapered shaft of the crankshaft. Removal of this nut needs a 11/16" wrench for the 4.5hp. If it is so tight that you can not loosen it normally, then try to tap the wrench with a medium hammer to jar the nut loose initially. If that does not work then you will have to resort to a air impact gun, but it should not be tightened this tight.

Most times if you just loosen the flywheel nut a few threads, (leaving it about even with the shaft end) then hold onto the flywheel by wrapping your arm around it and lift up enough to put a lot of strain on (almost holding the motor upright) then rap the nut HARD with a HEAVY brass mallet, the flywheel should pop off the crankshaft taper. The reason for the brass hammer is so it does not damage the nut or shaft threads. You could get by with a regular hammer if you are careful. One hard rap is better than a dozen love taps.

If this does not pop the flywheel loose, then you will have to resort to a flywheel puller as shown in use on my 6-8hp article. These usually have 4 slots milled in the top flange to accommodate the bolts to be threaded into corresponding threaded holes in the top of the flywheel. Here we will be using only 3 that are spaced evenly. This puller could be also use if only 2 opposing holes were there. The large bolt in top is threaded into the puller boss. In use you thread the 3 smaller bolts into the flywheel so that they will allow the puller to set evenly on top. You then tighten the large bolt into the puller, which puts pressure on the crankshaft end, pulling the flywheel up. If it comes really tight, then with the large bolt's pressure on the crankshaft, rap the large bolt head with a hammer, which usually will help and pop it off.

Electronics :

In the photos below you see the flywheel and

the electronics system

| Here you see the bottom side of the 4.5hp flywheel | Here is the CDI electronics on the 4.5hp timing plate. |

|

|

|

Recommended Fuel / Oil Mix : On these 2 cycle motors you have to mix the oil with the gasoline to lubricate the internal parts of the motor, so you need to know how much gas you will be needing, add the oil before you fill the fuel tank so that the oil mixes better than just dumping it in after you fuel up. Here you need to fill a totally separate tank with the mix and then add what you need into the motor's tank. This way you can refill a partly full tank with the known amount of oil.

Fuel/oil mix on all the OMC motors that have needle roller bearings (this motor included) is 50-1 of TCW-3 standard outboard oil. However I have found that since I troll much of the time, other than getting there and back, I like to use a mix of 75-1 but of a SYNTHETIC blend oil instead of the standard oil. This gives me at least the same or better motor lubrication, plus it gives me less smoke at a troll and the spark plugs last longer before fouling.

A quart has 32 ounces of oil in it. So for a portable two gallon tank to fill it using the 50:1 ratio would take 5 ounces.

The formula shown below will be on all modern 2 cycle oil sold

in the last 30 years or so. On most all of the pints and quart plastic

bottles of TWC-3 oils there will be a narrow clear vertical

window on the edge of the bottles. On the sides of this window will have

numbers representing ounces and Milliliters for other parts of the world.

Or you can purchase special measuring containers showing different ratios and

the amount of ounces needed.

|

FUEL MIXING TABLE |

||||||

| Gallons of Gasoline |

Gasoline to Oil Ratio |

|||||

|

Ounces of Oil to be Added |

||||||

| 16:1 | 24:1 | 32:1 | 50:1 | 75-1 | 100:1 | |

| 1 | 8 | 5 | 4 | 3 | 2.5 | 2 |

| 2 | 16 | 11 | 8 | 5 | 4 | 3 |

| 3 | 24 | 16 | 12 | 8 | 6 | 4 |

| 4 | 32 | 21 | 16 | 11 | 8.5 | 6 |

| 5 | 40 | 27 | 20 | 13 | 10 | 7 |

| 6 | 48 | 32 | 24 | 16 | 12 | 8 |

The official OMC fuel/oil mix for most outboard motors in this year ranges has for years been 50:1. This means 50 parts of regular gasoline to 1 part of outboard motor oil. Remember that this was before unleaded gasoline or even possibly an octane rating that was listed at the pumps. Now the recommended fuel is 87 octane gasoline.

Early on for the 2 cycle motors the recommended oil was regular automotive 30 weight motor oil, then the outboard industry came up with any TWC oil, which finally evolved into the latest which is TWC-3 outboard motor oil. You probably will not see much of the older TWC-2 oil out there anymore. You can spend your money and purchase OMC oil for about $6.50 a quart, or buy a name brand quart for $3.59. Sure the manufacturers want you to buy their oil, and for a new motor under warranty, it may be advisable to do so. But the consensus from many experienced boaters is to use any good brand of oil, as long as it has the TWC-3 rating, it meets or exceeds the manufacturers specifications. The TWC-3 represents, Two cycle, Water Cooled, type 3 formula. The formula 3 has decarbonizing additives designed to be more compatible with the newer non-leaded fuel.

So from the above information, you can see that fuel and oils have changed dramatically since these motors were first brought out in 1966. In this instance, times have changed for the good, as we now have a better gasoline along with way better outboard oils.

DO NOT use oil designed for your weed whacker or chain saws as these air cooled motors run a lot hotter than the water cooled outboards. The water cooled outboards require the specially designed TWC-3 oils.

Carburetor : For those of you unfamiliar with small outboard

motor repair, to remove this carburetor, unscrew the three top bolts holding

down the top plastic silencer/breather cover (29) in the illustration below.

The "Rich/Lean" idle knob can be pulled straight forward and off it's splined

shaft. Make a mental picture of which way the indicator

pointer is pointing so you can re-install it the same.

Then unscrew the retainer screw holding on the choke knob

(outside front of panel) and remove this knob. The rear of this

plastic choke rod connects to the carburetor choke arm by a small headed pin.

On some motors you may find the pin's head either on the outside of the

connector or inside. Remove this unthreaded pin. Now you can

withdraw the choke rod rearward and through it's hole in the lower plastic body

(#28). From there, the lower breather body can be lifted up and away

from the carburetor.

There should also be a foam rubber seal (#26) that may be

sticking the breather to the carburetor, if so, a bit of wriggling of the

breather body should dislodge it.

The carburetor itself is held onto the intake manifold by two

1/4" SAE nuts, one on each side (#33) (which uses a 7/16" wrench).

| Here the 4.5hp carburetor with the combo choke/fuel shut-off |

|

|

|

In the center of the

cowling is the Slow-Speed (idle) knob & combo choke/fuel shut off on left |

Here the Canadian combo lettering |

|

|

|

The carburetors used on

these motors varied with size of the motor and the year of manufacture. The early metal top ones

(1980-1983) are rather simple

units and quite reliable with a fixed main jet, otherwise called the "High Speed Orifice Plug" #24.

The hole size for the 4.5hp is #35. This numbers

relate to drill bit sizes. These early models have a metal bottom

float bowl, while the later ones can have a plastic bowl.

The slow speed idle jet screw (#15 in the

illustration below) has many small spline serrations on the outer end that mate

with splines in the hard rubber knob. The placement of this knob on the

front cowling makes for only 180 degrees of rotation. In doing any fine

adjustments after final assembly on the motor, if you can not get the knob to

rotate as far one way or the other to get a smooth idle, pull the knob straight

forward and off the shaft, rotate it 180 degrees so you get a better chance to

tune the motor. Then once I get this "sweet spot", I like to pull it

off again and position the pointer on the knob straight down, this gives me s

then known return position and about 90 degrees of movement either way if my

fuel ratio changes.

The normal number of

turns out from lightly bottomed out for the low speed (idle jet) #15 is 1 1/2

turns as a start setting. Many motor like 1 1/4 turns out.

The 4.5hp carburetor does not use a silencer as seen in the LH photo above.

On the RH photo below, the float bowl is plastic and you can see the makings of the "fuel pump", the bladder is the red part, held in by a plastic threaded nipple to the vacuum line. The upper nipple is the actual fuel line attachment.

|

The slow speed idle jet screw (#9 in the illustration above) has many small spline serrations on the outer end that mate with splines in the hard rubber knob. The placement of this knob on the front cowling makes for only 180 degrees of rotation. In doing any fine adjustments after final assembly on the motor, if you can not get the knob to rotate as far one way or the other to get a smooth idle, pull the knob straight forward and off the shaft, rotate it 180 degrees so you get a better chance to tune the motor. Then once I get this "sweet spot", I like to pull it off again and position the pointer on the knob straight down, this then gives me a known return position and about 90 degrees of movement either way if my fuel ratio changes.

The normal number of turns out from lightly bottomed out for the low speed (idle jet) #15 is 1 1/2 turns as a start setting. Many motors like 1 1/4 turns out.

Recoil Starter : This recoil starter uses a unique rotating/pivoting vertical gear that when the rope was pulled, the gear unit pivots up engaging the flywheel ring gear teeth which are on the under side, engaging the flywheel ring gear teeth which are on the under side, not outside of the flywheel. This version was initially used on the earlier 4hp motors and later used on these 4.5hp motors.

This starter assembly that is ALMOST impossible to assemble off the motor (like most others can be), as it has to finally preload the spring. It had to have been done at the factory, but they had the right equipment.

| Side view of the 4.5hp Johnson starter unit. |

One unique thing on the 4.5hp Johnson is that if the twist grip throttle handle is

advanced to FAST, the ratchet disengages and will not allow the motor to

be started. This featcher is not an the Evinrude.

In working on this one, try NOT TO let the rewind spring get out of the cage. It is not anywhere near what you may have encountered before, and you will have an experience.

It can be removed from the powerhead without taking the powerhead off the midsection/lower cowling as it just has enough room to get a wrench on this starter pivot bolt head. With that said, there is a trick to install this unit back on. In initially removing it from the powerhead, it may be best to BEFORE you start, to get yourself a 5/16" NC nut, so you can captivate this unit, by installing the nut on the rear of the center bolt as you remove the unit to keep the spring from unraveling. Upon reinstallation, be very careful to squeeze and maintain pressure as you start the center bolt and do it's final tightening.

In all

probability, if you have to replace the rope the rewind spring will not

stay contained, here is a description of how to rewind the spring.

If you have an original OMC service manual the last chapter tells you

how to install the spring. here let us assume you don't have that one. Read this a few times before starting, as I'm

probably leaving out some of the obvious stuff.

Before you start clean all parts in paint thinner and then

give everything a good coat of new light grease. And be sure the 3

Nylon bushings AND the flat washer in the spring cup are in place on the shaft to pivot,

otherwise it will not operate properly.

At the back of the spring cup there is a slit where the spring enters

into the cup and retains the spring's end loop when assembled.

If you had to let the recoil spring unwind in

order to get the outer tail end in the proper slot in the spring

housing, wind a few wraps in the housing, locate this exit slot in the

housing and get the spring going out (there will be LOTS of

uncaptivated spring outside) the housing now.

This starter pull cord goes on clockwise from

the outside, OR off the bottom of the spool.

FYI, someone said the length is

68", NO -- about all I can get on the spool is 54". With the recoil spring removed, wrap

(RH) the pull cord all the

way on it's pulley and then take an elastic band, or masking tape, and

place it on so the pull cord stays in the pulley.

In the initial assembly, the spool and outer cover needs to

have the small gear located between the 2 ears/stop tabs of the rear

spring cup.

You will see a hole in the casting looking at you where the

pivot for the small gear is. Fit a snug fitting drill bit in the

hole. This is designed to use the force the drill bit up so the

small gear stays meshed in the flywheel teeth. You now need to cut a

wooden wedge that will go between the top of the lower pan and up tight

against this drill bit, forcing the small gear into the flywheel ring

gear teeth. It has to be tight, otherwise the gears will un-mesh

on the final spring tightening.

| Here you see wooden wedge described above |

|

Once you get everything aligned and the unit bolted to

the powerhead, take a socket wrench on the flywheel nut and start

turning the flywheel clockwise (with spark plugs removed).

As you turn the flywheel the spring will commence winding

into the cup. Once the entire spring is in the cup go one

and a half turns more. Keep pressure on the drill bit (as

mentioned above) to ensure

gears stay meshed and the spring stays wound on and in place. You can remove the rubber band

or masking tape. Take the loose end of the rope out from the

spool, feeding it off the bottom and feed it out of the cowl, pull

enough extra and tie a slip knot on the outside of the cowl. Put

the handle on the rope's end and release your knot, and the rope should

wind back into the recoil. If you need it tighter, it is possible

to wind the rope one, or more times onto the spool, however it may

be easier to remove the flywheel to accomplish this, as you can now feed

the rope through onto the spool to tighten the spring and retract the

starter pull handle.

One thing that I have

found, the aftermarket 1/8" dia. starter rope is slightly tight in the

spool and may not want to allow the rope to fully recoil at first.

Here you may have to judiciously use some course steel wool to remove

the newness.

TIP --- Wear old clothes as I always end up filthy during recoil

work. And it my be best to have a few anti-depression pills

handy. And I challenge you to end up with a bright clean new

rope when you are done.

Remember, it is easier to preassemble it,

(held together by a 5/16" nut on the pivot shaft) then mount onto the powerhead.

| Exploded view of the 4.5hp starter unit. |

Cable Type Throttle Linkage : This 4.5 hp motors used a push/pull cable throttle linkage system. The routing and attachments are completely different on these two motors. Adjustment in the throttle positioning is accomplished by unbolting and screwing the outer plastic either in or out if you want to readjust the indicator pointer to the speed letters.

If this

twist handle seems hard to twist or to not want to move, the cable may be dry and binding inside,

or the timing plate may also be dry and dragging. To test this, removing

the end of the cable at the timing plate, now see if the handle will now

twist. If not, then the problem is in the cable. You may be able to

remove the cable, then get some penetrating oil in to lubricate it.

To disassemble this handle unit, you will notice two small round holes 180 degrees from each other top and on the bottom. You need to use a couple of punches, depress both of these at the same time, while pulling the handle off front-wise. A helper can be useful in this instance. Inside this plastic is a dual rotating cam slot which a cross-pin enters into spacers and rollers which is in turn attached into the cable end. When disassembling these be careful to not loose this pin.

After much usage the embossed Slow-Start-Fast indicators may get worn, however usually the start position is on top. The start raised rib on the twist handle is usually aligned with what may have been the Start position on the handle. When twisting the handle, the cable moves in or out.

The photo below shows the multi -function idle/kill button on the end of the twist knob. This style handle is activated by a internal cable from the handle to the carburetor. Inside the outer rotating knob, which is a low speed adjustment, is also a push button kill button. This rotating button/end knob when used for an low speed adjustment does not have any carburetor adjustment, but is used mostly by trolling fishermen who want a preset low speed other than having to each time they twist the handle to any other position, and want to go back to their preset slow position. In essence this is just a fine tuned low speed setting. The knob can be turned in or out. Out will usually come to a stop after a few turns, where in, once it has passed the few threads on the large inner section of this knob, will just keep rotating, but do nothing because it has simply ran out of threads.

If you can not get it to adjust, the cable to the linkage to the timing plate by unbolting it there and screwing the outer plastic either in or out if you want to readjust the indicator pointer to the speed letters. This can become frustrating. However they are a PITA to get really adjusted so most fishermen just forget it and visually adjust the low speed by ear and as seen on the twist grip handle.

| To disassemble, push in on the 2 plungers simultaneously (top & bottom) & pull the twist handle forward. This reveals the slider cams which engage a cross-pin which activates the in/out cable movement. |

|

In the photo below on the right, you will see the black plastic threaded outer cable attachment bolt on the thermostat housing and the pivot bolt at the end of the inner cable/ timing plate arm. You will also see a spare prop shear pin electrical taped to the plastic outer cable end.

| Here the RH side view of the 4.5hp motor showing the throttle cable coming from around & under the powerhead to the side of the carburetor above the powerpack & the fuel tank | |

|

|

Midsection & Trim / Tilt

:

There is a black

flatish knob, (shown in the photo below) located

close to the transom clamps of engine. When put in one position, it locks

the motor to the cross shaft, effectively locking it in that position, when the

knob is turned to the opposite position, it allows the motor to freely tilt up

or down. It has the words RUN on one side of this flat knob and TILT on

the other, indicating it can be raised, but the

wording or sketch usually get worn off so that it is hard to tell which way is

which and many heavy handed loggers may break off this plastic/Nylon knob.

This lock needs to be in the lock position if you use the reverse gear on the

motor so it won't kick up. However, if you plan on using the motor for

trolling in the shallows where you could drag the skeg, leave it unlocked.

This knob is made of black plastic and it it gets gunked

up, or sticky AND the operator is not sure which way it needs to be moved, the

thin outer part of this knob can become broken off. At this stage of the

game, TS, no factory replacement is available. And the owner now does not

know which way to move it, (which is usually locked into the NON-TILT POSITION).

The only way to get it unlocked from the housing (when mounted on the boat) not tilted or to access the inner part of this

knob shaft is to pull the adjustment pin (#23) in the illustration below.

This is the part that the lock fastens onto, so by pulling it out, you can now

raise the motor, inspect, lubricate things, maybe even remove the knob

shaft for repair.

This model is not designed with a tilt lock system as used on the later 6 and 8hp series. So if you need to keep it raised while running with your main motor, you may have to cut a 8" piece of wood about 1 1/4" square and place it between the midsection leg and the mounting bracket of this motor in the UP position.

|

Here you see the Red-Neck tilt lock assembly in use |

|

|

The clamp screws are 5/8" diameter and standard National Course threads. The upper and lower motor mounts are made of rubber and are the same interchangeable part. They appear to be very durable, plus easy to get to.

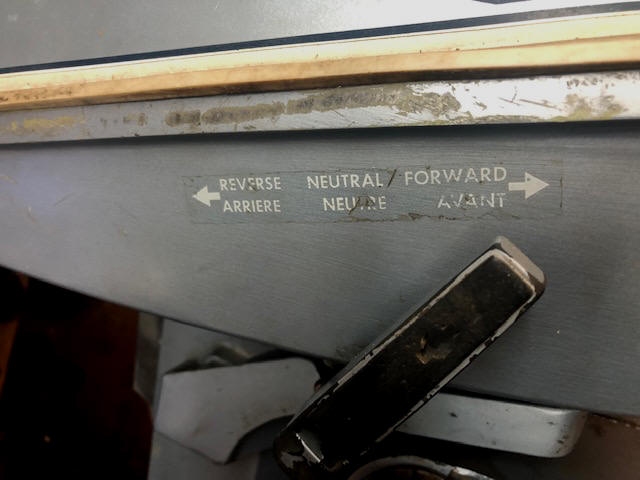

Canadian Inscriptions : The decals from the Canadian 4.5hp gear shifter lever include both English and French.

| Here you see the Canadian shifting inscription |

|

Shallow Water Drive /: There is a shallow water drive provision on the RH side of the pivot/mounting unit #65 in the parts illustration below. With the tilt knob activated so that the motor can be tilted up, lift the motor up slightly, move this #65 lever so it goes over center and you now have the lower unit held in a position about even with the bottom of the boat.

There is a fold out carrying handle tucked into the front of the clamping bracket as on the later 8hp series.

|

Here the twist knob is shown top LH and the lifting / carrying location is under the front base |

|

|

|

Mid-Section exploded view of the later 6 7 8hp series, with the only difference this 7.5hp does not utilize the tilt lock system (part #93 & 94 |

|

|

Water Indicator : These motors have the tell tale water indicator system common with most of the later motors. Here the 4.5hp is simply a small 5/32" hole on the bottom rear of the block, diverting this indicator water straight rearward and down. These seem to be a bit more trouble free as related to plugging up as the outlet hose to the overboard tell tale takes off the side-plate cover near the top instead of the bottom. This helps a bit in that it is less susceptible there to less debris plugging a outer tube. The Canadian motor has the same, but it diverts the water into the muffler (mentioned below), which then only has a mist exiting from the muffler's holes.

The 7.5hp would be similar to the 6-8hp article.

Muffler : These motors have a small plastic cover that covers the upper exhaust vent on the rear of the midsection (#80 in the above illustration). The name has been changed numerous tines. This does muffle the motor some, but in reality it was called a "water outlet" on these earlier models, it is also called an exhaust baffle on others. This muffler/outlet allows for some outlet water to mix with the exhaust gasses to cool the housing and at the same time allows only a small amount of exhaust with some spitting water, as an indicator of sorts, some may call it second exhaust port, however in actuality, in these smaller engines you could say it is an idle bypass, because at idle speeds there is not enough exhaust pressure to overcome the under-water pressure out the larger hole near the prop.

So if you see a slight amount of blackish oil coming out of the bottom of this, it is normal.

Water Intake : These motors main water supply to the water pump comes from a screened tube right behind the prop in the exhaust outlet which was carried over from earlier motors. Water is forced into the screened intake to the water pump by the prop thrust. Some users report that when running these motors in a barrel, (usually a small one) that the prop has to be installed and usually in gear as apparently they need to get more water pushed to the water pump by the prop to get enough to cool when running at over an idle.

There is no stainless steel intake plate on the left side above the cavitation plate like the previous versions. Aftermarket flush kits for this motor are obsolete and rather scarce. There is really no provision currently available for a easy muff system to run this motor out of a tank. But there is hope. I think that I may be able, (by tearing mine down) to figure out a way to drill/tap/modify the lower unit near the water pump to where I may be able to utilize the later screw in flush adapters on this motor. But that is a project in itself.

Overheat Problems at Troll or in Tank : If you happen to have the motor overheating at slow speeds, you might consider looking at the water intake screen tube which is situated in the lower unit directly behind the prop. This is placed here so that the prop thrust pushes fresh water into this slotted screen tube. This slotted screen could be inadvertently blocked enough that these holes could partially block water intake at a slow speed.

This slotted screen is made of plastic which would be hard to remove and save after many years, plus it is expensive to replace. So using a small nail or similar tool, you should be able to carefully clean any debris from the holes clear enough to make a difference.

When using this motor in a tank, always run it in forward gear as the water pickup tube is directly behind the prop, with the idea the prop will help push water into the pickup tube. If the tube is partly plugged and the motor is ran mostly in neutral, the motor may not be getting enough cooling water and overheat.

Water Pump/Impeller : These motors utilize a different shifting system. To disassemble this for water pump impeller replacement, there is a difference in the shifting rod from any previous motor of this size. It rotates instead of moving vertically as seen by the #10 & #78 bevel gears (located under the carburetor) shown in the midsection exploded views below . The upper end of the lower unit shifting rod is machined to match the #78 bevel gear coupler, which should just slide out and down when you drop the lower unit. The whole shifting rod then drops down and then out the bottom with the lower unit. This is a lot simpler to disassemble than the previous years.

Replacing it back into the midsection housing and re-aligning it after replacing the impeller may prove interesting. This CAN all happen without having to remove the powerhead, however it may take a bit of jiggling to get things to slide back together. The first part to align is the water tube, which slides into the long upper snout of the housing. This snout is considerably longer than most, so it helps get the tube started while you can still see inside the midsection from below using a flashlight. The tube's lower end is cut on a angle to help facilitate easy entry into the grommet in the upper end of the snout.

Second the driveshaft and finally the shifting rod. Initially I was worried about the shifting rod's re-alignment, but that was easy. The hard part was to align the driveshaft. It took a lot of eyeballing for the lower unit's upper mating surface to be even with the midsection's lower mating surface. After the driveshaft slid into the splines by slightly rotating the flywheel as you push up, the lower unit slid up to within about 3/8" then it went into the shifting rod gear easily. You can not see the shifting rod as it goes up inside it's own pocket, but it must have a internal tapered area at the top because things just slide in fine.

One thing that I have noticed on this type of impeller that uses these SHORT vanes, is that if left sitting for long periods of time, it will take a set, as compared to the older longer vaned versions.

OMC / Bombardier #0389576 water pump impeller $18.00, or Sierra #18-3091. This impeller fits Evinrude and Johnson 4hp, 1980-1992; 4.5hp and 7.5hp, 1980-1983; 5hp, 1996-2005; 6hp, and 8hp from 1984 to 2005 2 stroke engines.

| Water pump impellers, worn out & new | Water pump kit |

|

|

The experts say to not reuse a lower water pump plate if it is scored. Well this one had a couple of deep circular partial grooves in it. I disregarded the smaller diameter one near where the seal ridge of the impeller rubbed. But there was one larger wear groove out farther and near the outer edge. Not wanting to wait for a replacement, I took it to my band-sander and using a worn 240 grit belt, sanded this stainless steel plate from all directions to removed minute metal as evenly as possible. OH yes, you will need to dip into water after each sanding, as it gets HOT.

Thinning this plate should not have any effect on reliability as long as it was smooth, and this plate uses a gasket both on top and bottom, and the pump housing bolts on top. Maybe not recommended, but it worked.

The stainless steel cup looked in better condition so nothing was needed on it.

Lower Unit : They have a unitized gearcase accessible from the rear instead of the previous gearcase that split horizontally at the prop shaft line. The prop is driven on by a stainless steel shear pin 3/16"dia. X 1 1/4" long for both motors. There is a prop shaft nose cap on the rear is not screwed on, but a slip fit that is retained by a 3/32" cotter pin.

The new rotating shifting shaft cam in the lower unit, pushes a internal spring loaded rod that is in contact with the shifting clutch dog.

Remember that when you check/change gear oil, it is recommended to replace the drain plug plastic washer (#0311598) as they seem to be the most likely point of a leak.

The water intake is in the exhaust tube right behind the prop as used in the older smaller OMC engines as seen by the screen #24 hanging down in the exploded drawing below. And it offers no real opportunity to attach a currently made flushing attachment.

One thing they made provisions for was a recessed location in the lower unit to install a zinc anode, #47 in the exploded views below.

One thing I may warn you is that when you try to reinstall the lower drain/fill plug, is that IF the plastic washer remains in the hole, you may very easily NOT be able to start the threads straight. And this threaded hole sets at a slight angle with the outer housing when it is tightened in tight. If it looks like it is going in crooked, stop before you ruin what threads are left.

If the unit is full of oil, you may be able to lay it down enough to be able to remove the plug without a lot of oil draining out. A 3/8" X 16 NC tap can be ran in VERY CAREFULLY to clean up the slightly cross-threaded threads. AGAIN, VERY CAREFULLY and square with the hole.

| Here is shown the actual gear-case/Lower Unit |

Here the Lower Unit is in

exploded view for from 1980 to 1991 for 6, 7.5 & 8hp with the long & extra long shaft spacers being on the upper left |

|

|

|

To remove the lower unit on these motors there is one bolt in front that is quite visible (#5 for a short or extra long shaft, or #58 for a long shaft in the illustration above). There are also two more bolts underneath, above the prop (#56). Removing all three of these should allow the lower unit to be withdrawn from the exhaust housing and down to where you can remove it to access the water pump housing (#24).

If this does not allow the lower

unit to drop down, possibly some previous mechanic did not grease the upper

driveshaft splines and it is stuck in the crankshaft.

If this is the case, wooden

wedges driven equally around the midsection/lower unit may be your alternative.

Propeller

:

The

prop is a NON THRU THE HUB type.

The prop has a shear pin and the rear plastic

bullet nose is just a retainer that is held in place by the cotter-pin.

These props have a rubber hub bonded to the prop along with to the bronze hub.

On my prop the rubber must have gotten some corrosion between the prop and the

inner hub, forcing the hub forward about 1/16". This made it very hard to

get the shear pin in place while still having the brass spacer #54 shown above.

I tried to press the hub rearward, but no avail as the rubber was still bonded

(or stuck), so I simply chucked the prop in

the lathe and removed that amount off the rear of the prop to allow the spacer

to be in place and to accept the cotter pin #53.

The prop shaft is .531" or 17/32".

why this odd dia. ? Well my guess is that since most roller bearings and seals are actually made in

metric sizes, this .531 equals 13.5mm, so the seals would be more readily

available.

Prop Specifications ;

The 4.5hp prop is OMC / Bombardier #0391096,

a 8" X 7", 3 blade. The 7.5hp uses a 8 1/2" X 9" prop.

Paint

: OMC / Bombardier paint, spray can, Ivory #173744, Evinrude

light blue #173457.

Copyright © 2014 - 2023 LeeRoy Wisner All Rights Reserved

Back to the Main Ramblings Page

Originally stated 09-20-2014, Last Updated 01-21-2023

Contact the author

I have had numerous inquiries about a

simple cheap upgrade from the 6 to 8hp motors indicating the removal of a

restrictor plate behind the carburetor. Well in Europe, it was common to downgrade a

larger motor, the information I have, this would have been on the 15hp made from

1974 until probably 1992. However the only motors I have heard of doing

this, used a restrictor plate between the carburetor & the manifold was the

15hp, economically dropping it to about 10hp to comply with local HP

restrictions.

The only articles that I write about are ones that I personally have worked on that motor, so you may see gaps in my articles. However I have had a lot of requests for information on these older small motors, therefore this is info that I have found on OMC parts lists is as follows.

A lot of parts interchange between models and HP of closely associated motors in those days as it was simple to create "Families" of near HP size motors using the same parts.