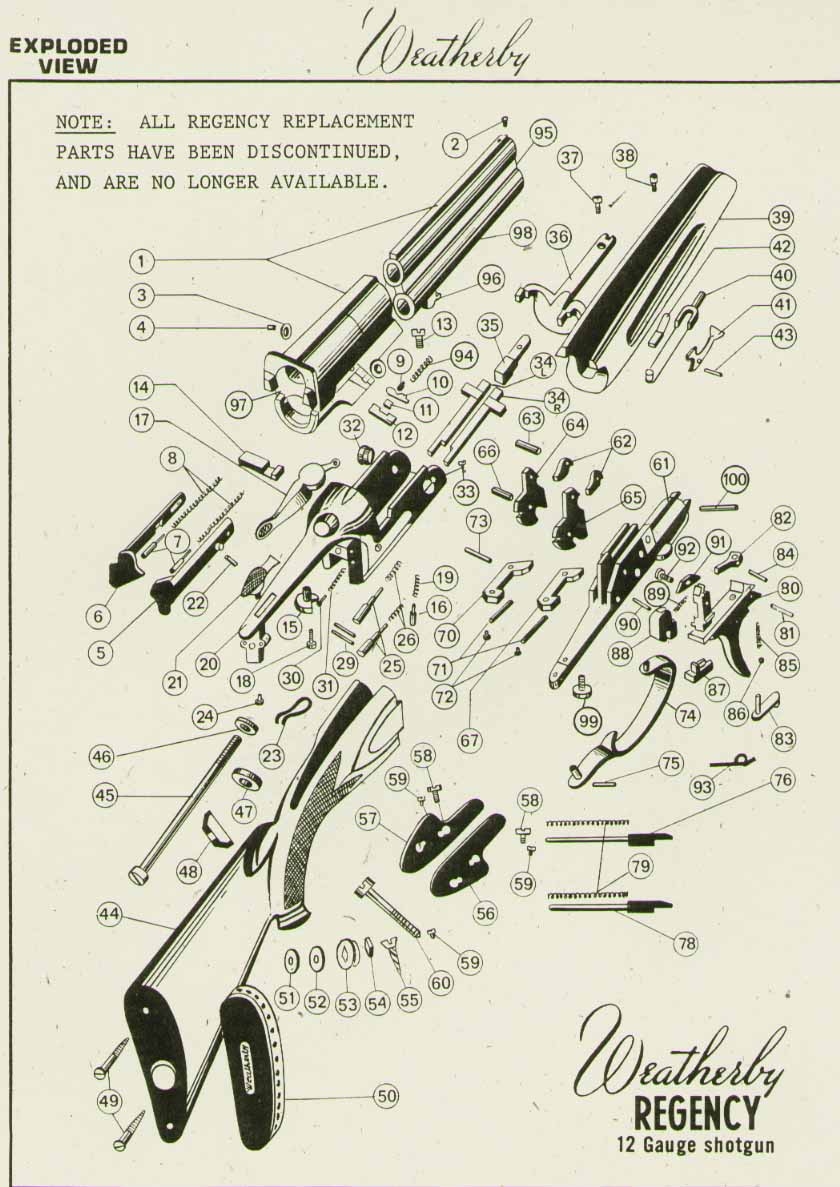

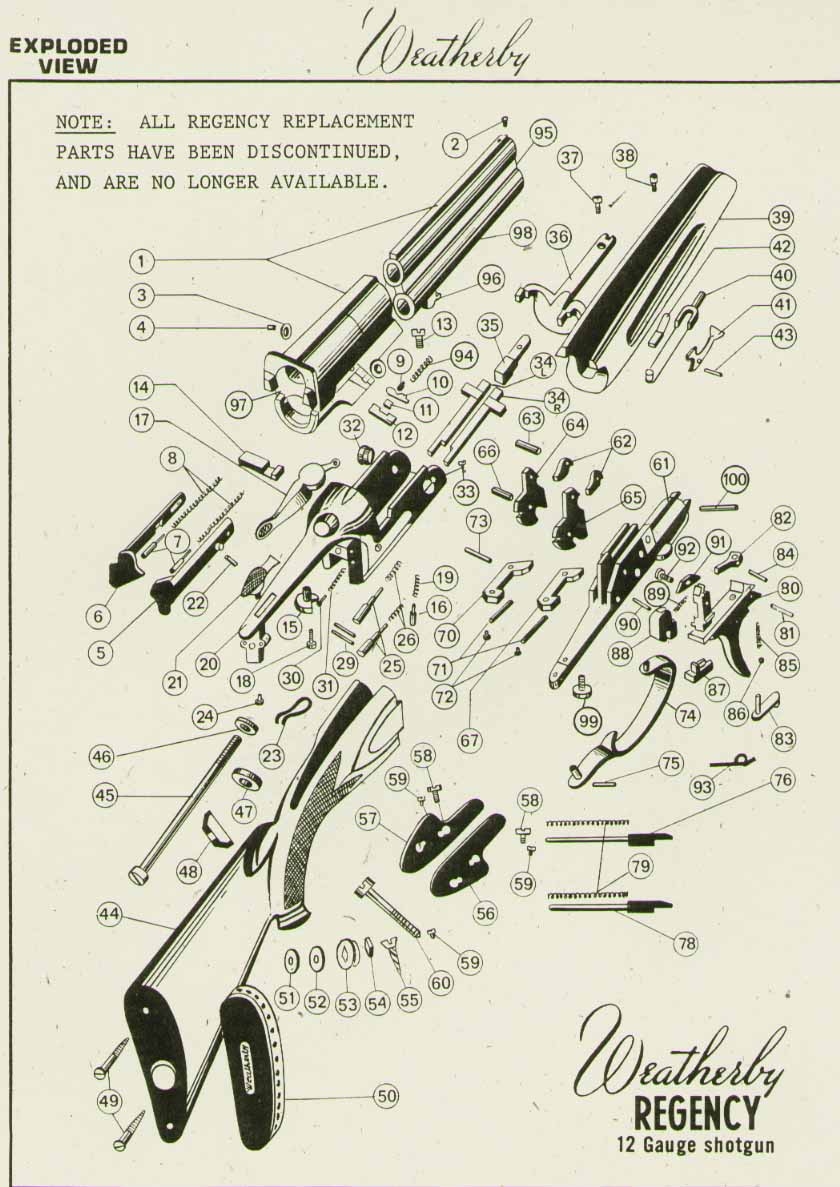

We thank Weatherby for supplying the above scanned picture

Weatherby Regency

Parts List

These illustrations were scanned off from Weatherby factory catalogs, and

ARE

factory ID and part numbers. This is important

as about all obsolete parts suppliers use

ONLY

factory or closely associated numbers

where ever possible so everyone is on the same page.

We thank Weatherby for supplying the above

scanned picture

Weatherby Regency O/U Shotgun

|

The parts listed below are for your

identification purposes only. The author of this website DOES NOT have any parts. |

Illustration #

35, Cocking Rod cam O/S

12 ga.

#3403.91

Illustration #

35, Cocking Rod

cam N/S 12 ga.

#3403.92

Illustration # 25,

Firing Pin 12ga. #3459

WEATHERBY REGENCY -

These guns were made by Angelo Zoli of Italy &

sold to Weatherby.

Not to be confused by his brother Antonio Zoli.

Angelo has been out of business for MANY years & Antonio's guns,

(sold under the Zoli name) were NOT the same.

So NO spare parts are available, as the "factory"

made these pretty much on order and had very few spare parts

left even when the gun was discontinued.

These

guns however, in reality were not all made by the same manufacturer. As it was a "Cottage Industry", in that MANY small

independent gunsmiths participated in this venture. Some shops may have made the barrels, others the receivers,

still others the wood &/or engraving.

And

who knows the assembly, with probably no one person or shop doing the complete

gun.

GUNSMITHING THESE GUNS - It is not known whether these numbers shown on the above illustrated parts breakout are ID numbers OR part numbers.

The common thought is that firing pins are bad if miss-firing occurs.

This is not the case many times.

The

mainsprings will take a set after time. Also if reloads are being used & the primers happen to be

upset when being seated, the primers are slightly desensitized & with the

weak mainsprings this can lead to a miss-fire problem.

Mainspring

plunger end (MS pilot) has changed from the factory parts drawing. The parts drawing shows a non captivated unit.

All that I have seen are the threaded together captivated unit. These

units are made for RH & a LH in that they need to be installed on the pivot pin

so that the upper part of the hammer has clearance when cocked.

If

miss-firing is encountered, first look at the mainspring rebound to see if

someone has had it apart & inadvertently threaded the plunger unit together

enough to shorten it. You can lengthen this unit (unthread it) so that the force

of the mainspring is still applying at the point where the hammer is bottomed

out.

If this does not solve the

problem, then you can make a spacer to go behind the front threaded end to

increase the mainspring tension.

This

is a fine line as you

will have to experiment with the thickness of this spacer to where the hammer

will still cock with the spacer installed.

The

hammers are basically a rebounding type stopped by the cocking rods.

If the above spacer still does not solve the problem, you can make firing

pins about .025 longer on the rear.

You

are essentially making them longer

&

somewhat converting the gun to non-rebounding hammers.

But these can't be too long in that they have to start to retract enough

when the gun is opened, so that they do not interfere with the opening of the

gun by dragging the firing pin tip out of & across the fired primer.

The

above situations are because, I

have not found any replacement mainspring that is strong enough.

The cocking rod cams are driven into a dovetail in

the rear of the forearm iron.

There

appear to be 2 different sizes as to width.

Information is not available from the factory as to serial numbers

when this

change took place.

On one gun using

the old style cocking cam has a #1 stamped on top rear of the cam.

#3403.91 COCKING

ROD

CAM - (Old Style .287 wide) appears to be the earlier version.

The

new style is a beefed up version in thickness and width.

#3403.92 COCKING

ROD CAM -

(New Style .376/.383 wide).

These

dimensions are taken on the widest part of the dovetailed end. The cams have a

small round hole going almost all the way thru in the middle of the dovetailed

section.

This is a removal indent.

You use a pin punch that will just fit the hole & drive the broken cam

rearward out of the dovetail.

In

fitting new cams, you may need to file the sides to fit a SNUG fit.

At this time

do not file much off the rear as this governs the overall length that

pushes against the pushes against the cocking rods.

They should be long enough so they cock the gun but do not leave the

opened gun hanging on this cam, as it needs to "Bottom Out".

Some replacement cams may need to be fitted as to OAL & rear

thickness for clearance to eliminate the chance of bumping the lower front of

the receiver.

There

are a few unique designs in this model.

One

is that the hinge pivot trunions are replaceable.

The reason is that they could not mill into a corner of the barrel's

mono-block.

They hollow end milled

this section from the outside, then made a ring that went over the now, center

peg, this ring was held in place by a small set screw.

The

matching receiver recess for this pivot ring was bored clear thru the receiver

sidewalls.

There is then a plug

inserted into partial depth of this hole & again using a small set screw to

hold it in place.

It appears these guns were only made with 2 3/4" chambers.

The

guns seem to be very well made & the only known problems appear to be the

cocking rod cams & the weakening mainsprings.

This page under construction &

the parts listing may be added later

Copyright © 2004 - 2015

LeeRoy Wisner with credit given for original illustrations. All

Rights Reserved

Back to the Main Ramblings

Page

Originated 05-17-04 Last updated

11-08-2020

Contact the author