| Weatherby Centurion & Centurion II |

|

|

|

Weatherby Japanese Semi-Auto Shotgun |

FIREARMS INFORMATION

This will cover the Centurion, Centurion II, and 82 semi-autos

made from 1972 thru 1989

These semi-auto shotguns

are

discontinued and have been for years, with most parts being obsolete.

We will deal primarily with the semi-autos here, however the pumps may be

mentioned, as they a are a parallel

gun to the semi-autos as they utilized many of the same parts. All

these guns have the model designation engraved on the LH side of the receiver.

You

may want to take a look at the exploded views page

CLICK

HERE as much of the nomenclature used by Weatherby on these

guns do not match what we normal associate with US made forearms.

They call the recoil spring links, carrier extensions, and the breech bolt

carrier, simply a carrier.

The one part that seems to give the most trouble, is the slide assembly

on the semi-autos, this will break, and

welding

usually is not successful. The main reason

I believe, is that there was no provision for a recoil buffer in this

firearm. Also we have found that possibly on a batch of slide arms

that the factory may have manufactured them by cutting the material cross grain

instead of with the grain of steel, resulting in a weaker part.

These

firearms were made by 2 different manufacturers, with even a phase-in / phase-out

overlap. We have not been able to find any differences in parts between

the 2, as the firearms appear identical except the serial number prefix.

| Weatherby Centurion & Centurion II |

|

|

Centurion ;

These

guns used a aluminum receiver, ventilated rib barrel, had a nicely

finished checkered walnut stock that had a white line spacer between the

rosewood grip cap. They used a non compensating gas system which

used only the recoil spring in the buttstock to absorb recoil without a stop

buffer in the rear receiver. The locking system and operating handle was

quite similar to the Remington 1100. Fixed chokes in the

barrels. The early versions used a single cast carrier extension

that was slotted down the center allowing the hammer to extend up thru the

extension when firing.

The

wood forearm front was counter-bored to accept the magazine cap so the cap was not

protruding from the wood. The magazine cap had detent notches on the rear

side that a spring loaded detent in the forearm counter-bore interacted with to

keep it from backing off.

Intermediate

Centurions, as with s/n A04905, used the newer carrier machined for the (2)

stamped extensions with a carrier extension that used two of the later single

type ones.

But they had a rivet at

the rear holding the two extensions together.

This configuration appears to be an intermediate version between the old

one piece cast extension but fitted to the new carrier that had a machined

spacer section to separate the extensions.

However the way the riveted extensions are made, they could have been an

early retrofit for the cast extensions IF a spacer was also used at the front.

The

later carrier extensions were simply a stamped out sheet steel, formed as

to made a RH and LH extension, with spacer (mentioned above) between

then at the pivot point where they are attached to the carrier. This

spacer separates these extensions so the hammer can move between them.

These slide arms have only (1) set of alignments pin,

while others have (2) at the silver solder

joint to the dog-bone.

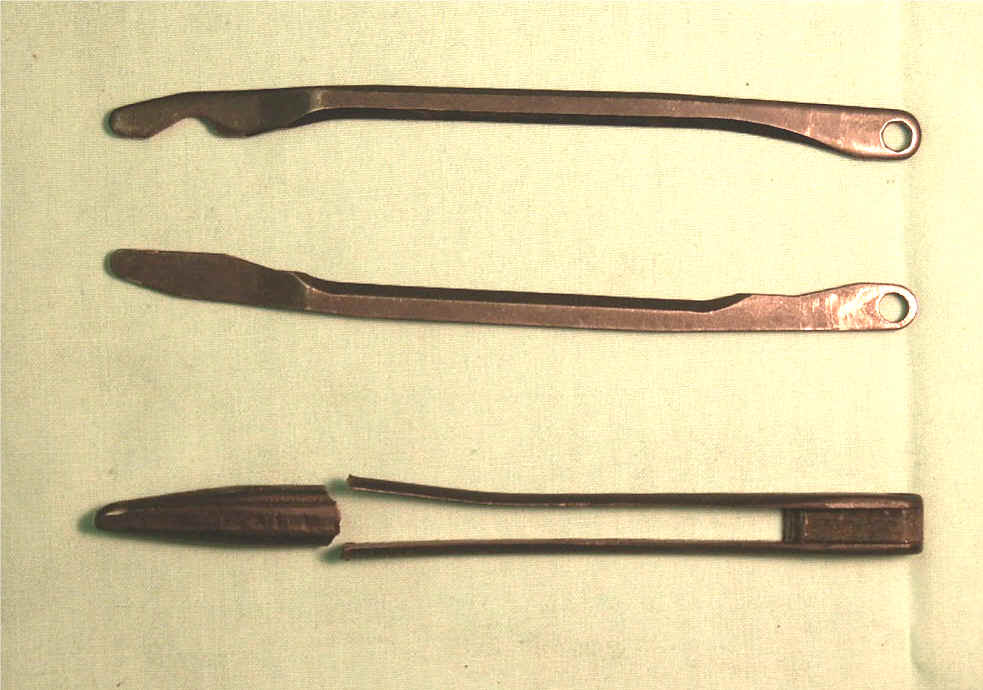

In

the picture below, the bottom illustration shows a broken EARLY one piece cast

Centurion carrier extension. The middle one is for a Centurion or

Centurion II. The top one is for a model 82 as evidenced by the cut

out in the LH end. This will be explained in the 82

section. You will note that these lower 2 have bevels on both

edges. These extensions are shaped and beveled so they will slide

inside the spring tube housing.

| Different carrier extensions | Shown on top is Wisner's conversion unit for the Centurion & model 82 |

|

|

| Shown immediately above is a broken slide assembly off a model 82 |

Wisner’s Inc. , was making replacement Centurion slide assemblies.

The Centurion II and 82 have a completely different slide assembly.

Wisner’s makes a carrier that when used in conjunction with the

Centurion slide assembly, will allow this Centurion slide assembly to fit and

function in the Centurion II and the Model 82.

They also make locking blocks, extractors, firing pins, operating handles

etc. for these firearms, and some other discontinued Weatherby models.

The

slide tubes for the Centurion have an overall length of just the tubing of

5.14". Some

early slide tubes have (3) equally spaced holes of .203 dia., back .600 center line

from the front of the tube.

The

thought here was that it may act as an initial gas bleed off, however the gas is

trapped in the piston, but this may have been a secondary relief, as the later

tubes were about 1/8 shorter.

The

gas piston has no writing on it so can be installed upside down, however the

forearm can not be totally assembled if in this manner.

The

gas tube has a .065 dia. x .750 long retainer pin 1.535" in front of the

tube's base that screws into the magazine tube.

This pin keeps the gas piston from falling off during disassembly.

The hole for this pin is in line with the (2) gas port holes.

The

barrel for the 2 3/4" ammo has two (2) #37 gas holes. The magazine

cap uses a bleed of representing a cross with the arms .095" wide and

.330 overall length.

Centurion Action

Slide Bars ;

It has

been noticed that the notches cut out on the bars (normally .500) on a few guns

is a longer dimension

.555+-.

Known guns with the longer notches are s/n NA0094X, and another s/n

NA0268X.

One customer who has

one of these low numbered guns and it is still unfired in the box, says it

does not have a model on the end of the box, just “automatic”.

These s/n would have put them as transition Centurions make by Nikko,

while they were also being made by KTG, during 1973.

It is not known exactly when the change may have been made to the later

more common

.500 dimensions.

Also

on these early guns the slide bars were radiused on the rear.

The Patrician used a LH slide bar that was angled off on the rear to act

as a slide stop.

This necessitated

the need for 2 different bars in production.

Later they simply used the Patrician bars on both the guns.

However we have found that the first Centurions with the wider notch apparently

needed the shorter radiused LH bar end.

| Slide assemblies for 82, Centurion II, & Centurion | Differences

between |

Good Centurion on top, center & bottom are damaged units |

|

|

|

|

In the photos above on the LH bottom is a Centurion slide

assembly with a original carrier in position. Above it in the center is a

model 82, on top is a Centurion II slide assembly. Center

photo shows the Centurion on the bottom, the newer type Centurion II and

model 82 on top. On the RH photo you can see a good Centurion slide

assembly on top with two broken ones below. The bottom one is

actually off a model 92 as evidenced by the flat angled rear and the notch on

the bottom on the RH bar. Most of the

Centurion breakages are one or both slide bars will break off at the rear

notches as shown above.

| Bottom view of carriers, both semi-autos & pumps | Top view of carriers, both semi-autos & pumps | Centurion II gas system with forearm removed |

|

|

|

|

In the above Bottom Views photo, the top LH part is

Wisner's conversion carrier which in addition to a Centurion slide assembly,

converts to the Centurion II and model 82. Again in LH photo, left middle

is a original carrier for the

Centurion II and the model 82. Bottom

of same column is an original Centurion carrier. Note the shallow

groove lengthwise of it. This is the pad that cocks the hammer when

the action cycles rearward.

On the

RH side of the same photo are a broken model 92 on top with a original Patrician

on the bottom. The part that is broken on the 92 is the thin web that is

missing on the upper RH part of it.

In the above center views photo, the same parts are shown in same sequence as on the LH photo are shown, except flopped 180 degrees showing the top side view.

The RH

photo shows the gas system of a Centurion II, with the forearm removed.

Centurion II ;

The

Centurion IIs have the same receiver configuration as the regular

Centurions abd will have that model engraved on the LH side of the

receiver. Internally they are basically the same as the regular

Centurions, with the exception of an "improved" slide

assembly.

This

improvement is not really improved except it was easier for them

to make out of stamped parts. The tube was lengthened from to 6.14", was silver soldered to the slide arm stamping. The normal breakage here is that the the stamped metal slide bars will break at

or near the rear bend where they form a bridge and are connected to the

carrier.

This

gun also used a spacer of .233 front to back thickness with 1.157 dia. on the

magazine tube, against the receiver's front.

It appears this spacer acted as a dual stop, abutting against the rear of

the slide assembly tube and the front of the receiver.

This was timed so that the action bars are stopped at the same time the

rear of the carrier hits the inside rear of the receiver.

The forearm had a thin dual thickness C shaped metal liner of .500"

glued into the rear of the wood.

The

dual thickness involved the thinner part to blend in with the forearm's inner

hole and the rear thickness had a close fit over the above mentioned spacer.

The carrier was changed to match this

new stamped out slide assembly. The hammer was also changed to match the

combo of the slide assembly and carrier. The hammer was made lower from

the cocked notch to the cocking pad that the carrier rides over during the

cycling action. A Centurion hammer (being taller) installed into a

Centurion II trigger group will not allow the slide unit to move to the rear far

as it can not go deep enough in the II housing and will bind things to a stop.

The

Centurion II was made in either 2 3/4" or 3" barrels. The

2 3/4" barrels are the same as the corresponding Centurion barrels. We can not find any

difference in the gas system between the 2 chamberings other than possibly the

size and number of gas holes in the barrel for the 3".

The ejector is slightly different than the regular Centurions in that it's tail

was shorter by .200 and it does not have longitudinal grooves of the #3205.

The reason for the shorter ejector tail was apparently because these guns could

have been had in 3" where this one part could function for either depending

on the barrel it was fitted with.

| Model designation on receiver of Centurion II | Top illustration is a model 82, with the bottom being from a Centurion & Centurion II |

|

|

Model 82 ;

These

guns were introduced in 1982, so possibly the reason for this model

designation??? These were made in either 2 3/4" only or 2

3/4" & 3" chamberings, with screw in

chokes while still using the ventilated rib barrels. The 2 3/4"

barrels use two (2) gas holes of #45 size while the 3" barrels use one (1)

size #45 hole. Both use the same magazine cap which has a

.250" dia. gas bleed off hole in the center. Barrels

appear to be available from 26" to 30".

The screw in

chokes were installed into a swaged up bore to accept the threading for these

chokes. These barrels are swaged up from about .830 (depending on

the length) to .905" at the muzzle to accommodate the internal threading

for the screw in chokes.

The 82 receiver was

again made of aluminum, but was slightly modified to a semi

hump-backed rear. Stocks

were pretty much the same configuration and design as the Centurion series

however they appear not quite as bulky. The forearm was shortened allowing

the magazine nut to protrude forward, which made it easier to take down as

compared to the Centurions.

The

slide assembly was again "improved" but again using the stamped, bent

sheet steel of the Centurion II but utilized a floating tube held in place by a

wedge. The tube was shortened to 2.50" long. It is common for

these slide assemblies to break at the pivoted wedge. Here the best

repair is to silver solder the tube to the bar unit.

Extractors

were the same as the Centurion series, however the plungers and springs were

made smaller. Firing pins and springs were also changed.

| Year | Mfg Weatherby model Serial Number range Gauge |

| 1972 - 1974 | KTG Centurion Auto AO00001 - A07405 12ga 2¾” |

| 1973 - 1975 | Nikko Centurion “ NA00400 - NA10091 “ “ |

| 1976 - 1979 | Nikko Centurion II “ NA10884 - NA17754 12ga 2 ¾” |

| 1976 - 1979 | Nikko Centurion II “ NA10884 - NA17754 12ga 3” |

| 1979 - 1981 | KTG Centurion II “ A17755 - A18878 “ “ |

| 1982 - 1989 | KTG 82 Auto 82-00001 - 82-11527 12ga 2 ¾”/3” |

| 1972 - 1976 | KTG Patrician Pump SO00001 - S05089 12ga 2 ¾” |

| 1973 - 1975 | Nikko Patrician “ N00001 - N00011 “ “ |

| 1973 - 1975 | Nikko Patrician “ NS00500 - NS12863 “ “ |

| 1976 - 1981 | Nikko Patrician II “ NSI2922 - NSI8148 12ga 2 ¾”/3” |

| 1982 - 1989 | KTG 92 Pump 92-00001 - 92-11990 “ “ “ |

We have recently seen pictures of a

Nikko Super Express 7100 12ga in serial number range of J0039X that

appears to be an almost exact copy of the Weatherby Centurion.

The author does not have any source of parts for any of the firearms listed above

Copyright © 2004 - 2023

LeeRoy Wisner with credit given for original illustrations. All

Rights Reserved

Back to the Main Ramblings

Page

Originated 01-15-2006

Last updated 04-13-2023

Contact the author