| Breech bolt from a 1891 Sideloader | Here are the 1891, 1892/1897 & late 1897 breech bolts shown from the bottoms | The same bolts as pictured on left, but shown from the top, note FP tip width differences |

22 RF model 1892 &

32 RF model 1891 |

|

|

|

|

|

|

Marlin Lever

Action Rimfire |

FIREARMS INFORMATION

The Marlin lever action 22 rifles were

invented by L.L. Hepburn and first introduced as the model 1891, (which had 2

series).

These were hammer type

firearms typical of the period when they were introduced. The 1891 did not

have any model numbers stamped on the upper tang like the following models did.

It seems that many of the early firearms companies, when they first came up with

a new model, that they never envisioned improving it, then changing the model

number for the newer model. The model 1892 and 1897 continued simultaneously

until 1915 when the factory tooled up for military contracts for WW I.

The model designation for 1892 and 1897 was changed to just model 92 and 97 in 1905.

After the war, the company reformed in 1922 and the model 39 emerged.

Then in 1936 the model 39A appeared as a further improved version yet.

Some parts do interchange from the older guns, BUT?

No guns were made from 1942 to 1944 during WW II.

There were lots of changes and different variations between 1939 and 1988.

Ordering replacement parts can get

confusing, since many of the parts are shared with different models as the

transgression progressed as improvements were introduced.

Then there is the fact that the factory probably utilized as many parts

as possible on the later guns until the old parts were exhausted. So there

could be an overlap.

Or scavenged parts off any close model (some will interchange but not be the correct vintage) could have been acquired by previous owners.

The serial numbers did not start with 0

even for the original model, as the factory mixed serial numbers with ALL other

models being made at that time.

In ordering parts, the part number on the

older catalogs had a number and a letter.

The numbers usually did not change from catalog to catalog of different years,

however the letter would.

So you

could see a 57G in one catalog, the next years catalog COULD be 57F for the

same part. Many catalogs simply requested the user to supply model,

caliber and serial number of the firearm in question. A later

intermediate catalog, then utilized a model number prefix added to the part

number, as 39-57 for the same previous part. However some lists have a number different.

This part number following the prefix COULD have been taken from the previous

non-prefixed catalog, but not always.

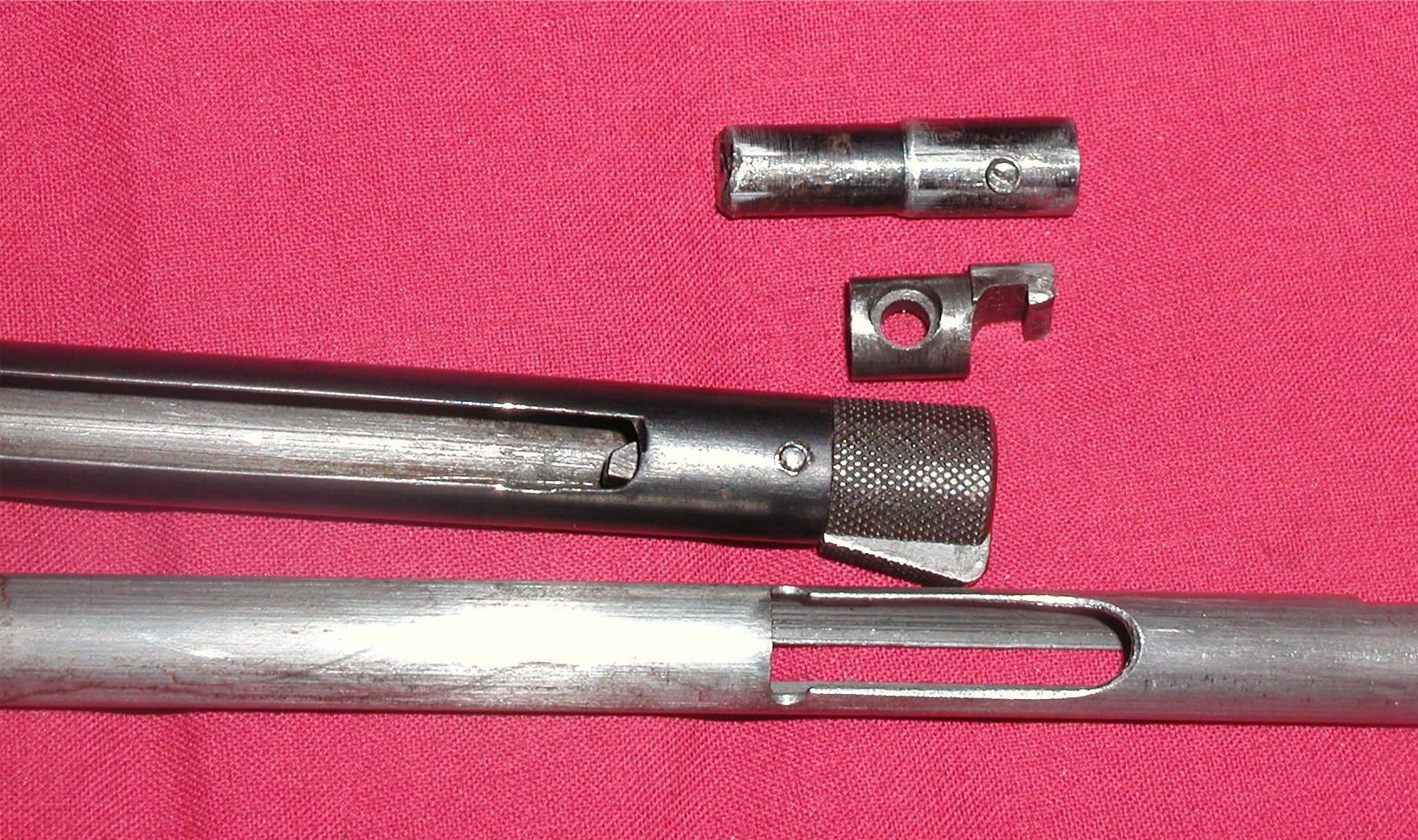

Firing pins were totally different for the 1891 and 1892, (except for possibly a overlap during the 1st year of the 1892) as compared to the 1897 and 39 series. The firing pins have a notch with extensions both front and rear of this notch. The notch is where the upper end of the finger lever rides to move the bolt forward and back. This part of the lever rides in this notch which also retracts the firing pin. If the wrong firing pin is placed in a bolt, the lever may well bind.

As time moves on and you get into the model 39 series, the factory used letters in addition to numbers added to the part numbers. These letters were usually "A" either as a prefix or suffix to the model followed by the part number. However they did not see far enough in the future that the next model would become the 39A. Since there was already an "A" behind the model number, they then placed it as a prefix in addition to the already used suffix. Therefore you can see a A39A-32 part number.

Notice on the LH picture below, the bolt has no slot on

the RH side, as compared to the other bolts in the other pictures. The

early 1891 firearms did not have this feature. This slot on the later guns

also has a matching protrusion in the frame at the rear. This was designed

so that if you take the sideplate off, or take down the gun, that the breechbolt

will not just fall out. It has to be positioned to the proper

location before it will come out of the receiver.

To help identify the 2nd from the left illustration below, the center breech bolt, as compared to the RH one. Viewing from the bottom, the round hole shown is where the 1/2 round retainer portion of the extractor fits. This hole being a retainer for the extractor as well as a means of removing a broken one, goes all the way thru the breech bolt. The extractors for the 1891, 1892, and early 1897 were #25G. On the LH picture, the RH bolt uses the later #39A-26/27 extractor that has a separate spring. There appears to be some slop over as to which extractor fitted which gun in the transition of the 97 / 39, whether this happened in a transition period or possibly the breech bolts could have been changed somewhere in the firearm's life.

The 3rd from the left picture shows the same bolts as in the LH picture. The 1891 firing pins have a narrower tip than the later models. Note the face of the bolt where the firing pin protrudes is a different width on all 3 bolts. Also note that the firing pin slot hole that goes thru the bolt about midway has a shorter slot for the model 91. Here you can see the differences of the slots for the extractors, with the 91 bolt having the extractor still in it. The RH 97 bolt has been broken and brazed back together. Later bolts were machined differently to eliminate this weakness.

| Breech bolt from a 1891 Sideloader | Here are the 1891, 1892/1897 & late 1897 breech bolts shown from the bottoms | The same bolts as pictured on left, but shown from the top, note FP tip width differences |

22 RF model 1892 &

32 RF model 1891 |

|

|

|

|

|

The

firing pins for the late 92, 97 and 39 should all be interchangeable, however

there were 4 different versions of the tip section. The last version

will function with all the previous ones. The extractors of

course have to match the corresponding vintage breech bolt.

On the RH picture above, it shows the differences between the 1892 22RF, showing the longer slot for the firing pin as shown in the other pictures, as compared to the wider front for the 32 caliber and the shorter firing pin slot of the model 1891. The extractors are the same for both calibers as evidenced by the distance between the extractor slot and the firing pin slots.

Model

1891 Sideplate Version :

The first this series of rifles was introduced as the model 1891 in 22RF

only.

The 24" barrel could have

been had in either round or octagon. It was a side eject 22 Long Rifle,

that utilized a side loading gate thru the RH sideplate. This sideplate

was removable to access the internal parts after unscrewing the thumbscrew.

The magazine tube was under the barrel that was shorter than the later

versions.

The trigger and sear were 2

separate parts with a lever disconnector much like the Winchester model 94.

This trigger disconnector was what Marlin used and

advertised as the "Marlin Safety",

which was engraved on top of the receiver.

It could have been had in either a straight or semi-pistol grip style.

The extractor was made so that a 1/2 of a circle protrusion was on the

side of the shaft, holding it into the breech bolt.

The ejector was a spring with a rounded flat ball on the rear, which had a

hole in this ball end that a screw went thru which was screwed into a slot on the LH

side of the receiver.

The side loader 1891 was replaced with the

more commonly seen 1891 tube loader

after about 5,000 guns.

All of

the model 1891's used as a cartridge stop, a flat twisted spring that was

screwed into the upper part of the sideplate.

They did not utilize a cartridge cut-off so only 22 Long Rifle ammo could

be used.

| Model 1891 Sideloader |

|

Model

1891, Standard Version :

This model used

the same 2 piece trigger as used on the sideloader model.

The regular tube loader is different than we are used to

today, in that the outside tube pulls out to allow you to load ammo into the

inner tube.

It was a machining

nightmare in that there are lengthwise slots about the full length of both the

inner and outer tubes.

The magazine

latch was a knurled lever on one side of the magazine plug.

The knurling on both the lever and plug matched. When the tube

loader 1891 was brought out, they also added a 32 caliber version.

This 32 caliber was made so that either a 32 RF or a 32 Colt center fire,

could be fired in the gun by simply exchanging the firing pin.

This version of the magazine tubes are very prone to malfunctioning. There is a small tab on the rear inner end that in conjunction with a tab on the follower allow the follower to be retracted forward by means of the lengthwise inner slot, when the outer tube is pulled forward revealing the loading slot in the inner tube. Things can easily get bent or broken between this tab, the follower's corresponding tab. Then when it is disassembled for repair, things DO NOT go back in exactly reverse order, again bending or breakage can occur. Many times this old tube can be repaired by a COMPETENT gunsmith.

| Standard magazine tubes, inside & outside for 1891 standard version thru model the 97 |

|

The screwed in ejector gave way to a "double spring"

type in 1897.

This double spring

version utilized a separate flat spring that was staked into the back side of

the new ejector, quite similar to the Winchester model 12 shotgun ejector.

The 22 ejector was longer than the 32 ejector to accommodate the shorter

case.

The extractor was the same part, (different part numbers

on some) for the 22 and 32 calibers.

The breech bolt for the 32 had the extractor slot milled outward the distance to

accommodate the 22 extractor with the slot being lower allowing the 22 extractor to

ride nearer the center of the 32 rim.

A cartridge guide was utilized in the upper LH side of

the receiver.

It was a flat twisted

spring, that laid in a recess in the receiver, which was held in by a screw but used

only on the 22 caliber firearm.

To accommodate the 32 caliber in a 22 frame, they

machined a recess out on part of the inside of the LH receiver, about the same

on the inside of the sideplate to accommodate the larger case rim.

The case then being longer, they had to lengthen the lever throw.

This was accomplished by milling out a slight amount of the receiver

immediately in front of the lever.

This allowed the lever to have more forward movement after they made a relief

cut on the rear of the lever to give clearance for the takedown screw in this

longer throw.

The 32 caliber guns used a “double spring” ejector,

which was very similar to the model 1893 centerfire rifles, only that it was

slightly narrower.

Receivers had a rounded top with the word “Marlin

Safety” prior to 1903 when the Hepburn Rocky Mountain combo Peep/Vee rear sight

was introduced.

Then it had a flat

top to accommodate this peep sight.

This model did not have a cartridge stop, so could only

function with 22 Long Rifle cartridges.

As said before, the model 1891 serial numbers did not start with 0. It however appears s/n's are as low as 47,889 have been observed to as high as 77,943 with a total of 18,643 made.

The model 1891 was made in both the straight or 1/2 pistol grip style stocks. Mainsprings and tang screws will be different for these 2 different versions, also the buttstock of course.

Model

1892 :

The model 1892 used the same removable sideplate as the 1891, but the gun was still full length, non takedown.

The first year production 22 caliber still used the screw mounted ejector of the 1891. After that the spring type ejector was utilized, which also could be interchanged, substituted into the older screw type mounting slot. Then in 1907 the newer ejector system now used on the model 39 was introduced. This type is totally different, being inset into a milled slot on the LH side of the receiver, held in place by 2 small screws from the outside.

The model designation was changed in 1905 from model 1892 and or 1897 to just the model 92 or 97.

The cartridge stop of the 1891 was carried over and a

cartridge cut-off was added to this model.

Approximately the first two years of production saw the screw type

ejector used.

Then the

"double spring" ejector appeared only to be replaced in 1907, by the

newer "2 screw ejector" that is still used in the current model 39A's.

The 1892 also came in either the 22 or 32 calibers.

The early models were prone to loosing the complete

breech bolt unit and firing pin if the sideplate was removed or the takedown screw

came loose. So the later versions had a lip machined on the back side of

the breech bolt that engaged into a recess in the lower receiver/TG unit.

This allowed the breech bolt to remain in the disassembl

The magazine assembly of the later 1891 was carrier over and used on the 1892 and 1897.

A cartridge stop was added, so the gun could function with 22 Short. Long or Long Rifle ammo.

| Model 1892 32 caliber, non-takedown, note recess in back of receiver to accommodate wider bolt protrusion | Model 1897 shown taken down, with patent date visible |

|

|

|

Model

1897 ;

When the 1897 came along in that year, it was what we know as the true

“Take Down”, as loosening the sideplate screw allows the firearm to be

disassembled into 2 halves with the barrel and front receiver unit in one unit,

while the buttstock and trigger housing unit being in the rear unit.

The 1897 was made only in 22 caliber.

The model designation

was changed in 1905 from model 1897 to just the model 97.

The magazine tube assembly was the same as with the 91 and 92’s, except for the last 2 years of production, which utilized the same basic magazine except it had a button at the front for the release.

| Shown here is Wisner's magazine conversion assembly #39-49/50, replacing the original 91, 92, 97, & 39 22 RF magazine units with the new style tube unit, as used on the 39As. Wisner's inc also supplies a new replacement ring |

|

|

|

|

Model 39 :

The model 39 was born in 1922.

It was identical to the pistol grip, octagon barrel model 97 version.

The 24” octagon barrel

was

all that was available.

The rear of

the pistol grip lever had the slight S curve to it where it met the lower tang

as did the model 97.

Top of the

tangs were all marked

Marlin/MOD

39.

Some of the top tangs were also

marked with a * which indicated that the gun was a near perfect as it could be.

Breech blocks were still made in the configuration as previously and were weak enough that breakage could occur if using Hi Speed ammo. These were identified by either no prefix to the serial number or a prefix of “S”. In 1932 the machining was changed where it was then acceptable for and recommended to be used with Hi Speed ammo, the serial number prefix of HS was then added.

Magazine tubes were a carry over from the late 97 model.

| Magazine tube locking system for late model 97 & 39 |

|

Model

39A :

The magazine unit on the 39A was changed to the

removable bayonet type retainer shown above, that we normally see now on most

all the 22 rifles.

No guns were made from 1942 to 1944 during WW II.

In 1945 the receiver was changed from a case hardened color to simply a

black oxide type finish.

It boasted a round barrel, beavertail forearm and a

classic pistol grip.

In 1961 a

deluxe PG version was introduced.

There was a “Mountie” version with a straight grip also in the mix.

The later 39A (2nd variation) had the lever

support lug integral with the LH side of the receiver.

The cartridge stop, which is located in the upper top section of the LH receiver consisted of initially as with the earlier versions, a twisted flat piece of spring that was screwed into the receiver at the rear. Then a machined square bar that had a coil spring behind it to apply tension. Then finally it was eliminated all together.

In 1983 the 2,000,000th model 39 was made.

Model

39AS :

In 1988 the “S” version was introduced

as an improved version of the 39A.

This was the addition of a hammer block safety and a rebounding hammer,

which no doubt was brought into being by the thought from the factory's legal

department that a safety was needed, even though the hammer and the shooter's

mind had done this for a considerable length of time. Got to make it safe

to avoid a law suit.

Copyright © 2004 - 2020

LeeRoy Wisner All Rights Reserved

Back to the Main Ramblings

Page

Originated 05-11-04 Last updated 11-28-2020

Contact the author